Co3O4 nanometer array super-hydrophobic material coating and preparation method thereof

A nano-array and super-hydrophobic technology, applied in textiles and papermaking, fiber treatment, carbon fiber, etc., can solve the problems of high equipment requirements, high equipment requirements, and poor applicability, and achieve wide applicability, economical process and easy operation. Solve the effect of harsh preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

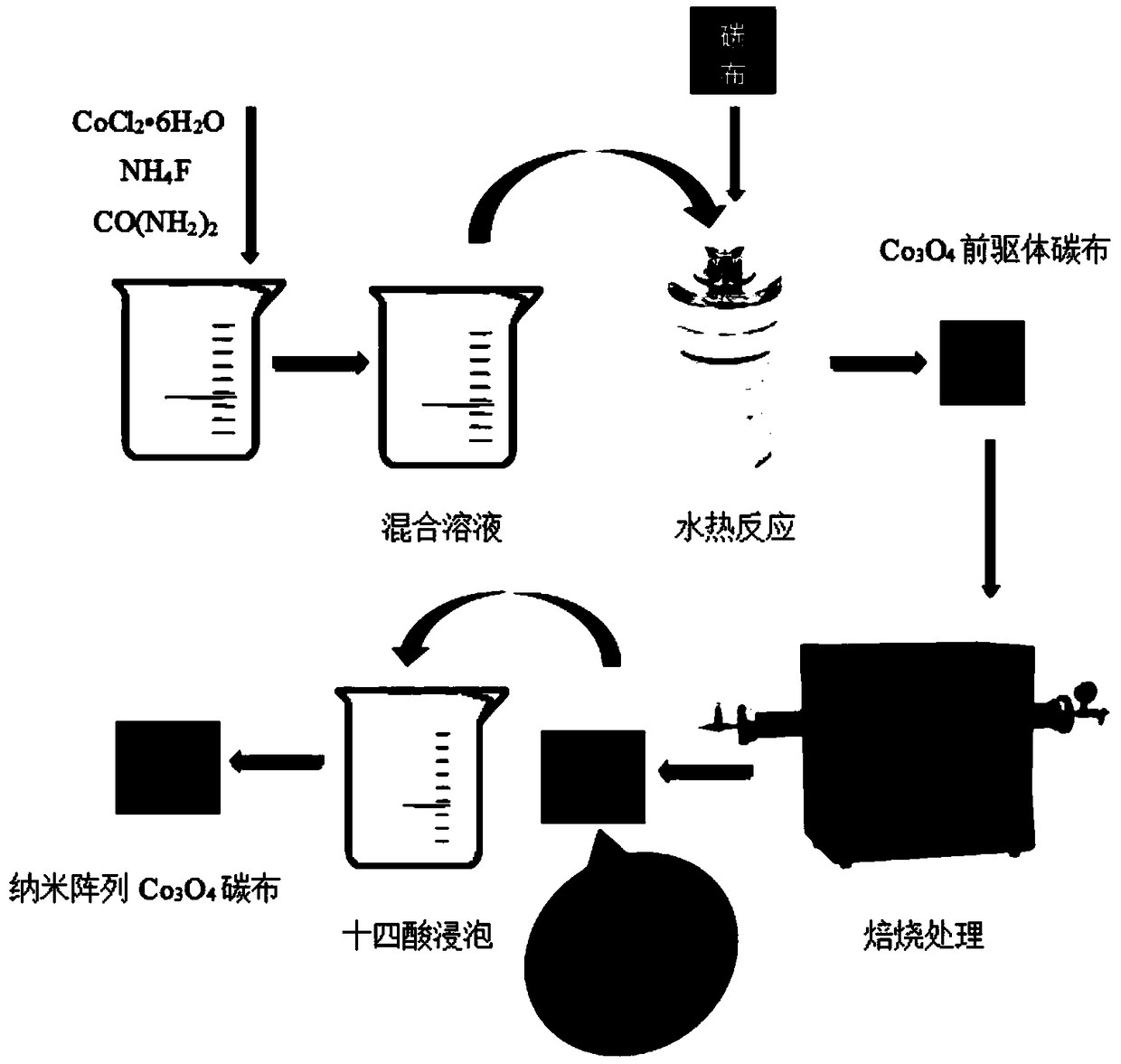

[0022] Reference attached figure 1 process, a Co 3 o 4 A preparation method for a nano-array superhydrophobic material coating, comprising the following steps:

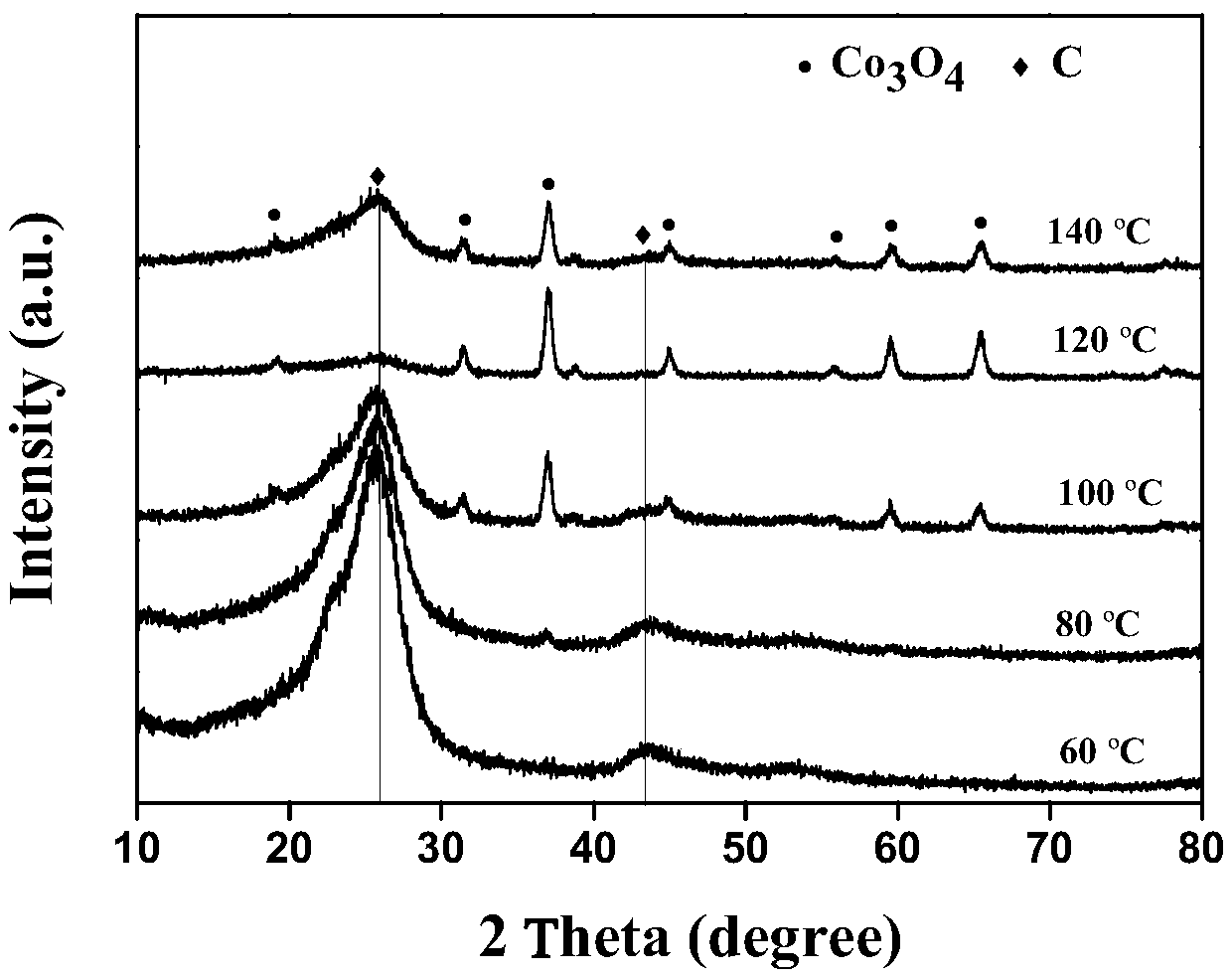

[0023] (1) Synthesis of cobalt trioxide nanoarrays: Put the pretreated carbon cloth into 20 mL of CoCl with a concentration of 0.08 mol / L after being ultrasonically cleaned with acetone and absolute ethanol for 5 min, and then washed and dried with distilled water. 2 ·6H 2 O, 0.112mol / LNH 4 F and 0.144mol / L CO(NH 2 ) 2 Then put the mixed solution immersed in the pretreated carbon cloth into the oven in the reaction kettle and heat it to 100°C for hydrothermal reaction for 12 hours. After natural cooling, cleaning and drying, the carbon cloth with pinkish-purple solid on the surface is obtained. That is, the precursor of tricobalt tetroxide; after that, wash with absolute ethanol and distilled water, dry the precursor of tricobalt tetroxide at 60°C, and then put it into a tube furnace for roasting at a temperatur...

Embodiment 2

[0026] Reference attached figure 1 process, a Co 3 o 4 A preparation method for a nano-array superhydrophobic material coating, comprising the following steps:

[0027] (1) Synthesis of cobalt trioxide nanoarrays: Put the pretreated carbon cloth into 20 mL of CoCl with a concentration of 0.09 mol / L after being ultrasonically cleaned with acetone and absolute ethanol for 5 min, and then washed and dried with distilled water. 2 ·6H 2 O, 0.126mol / LNH 4 F and 0.162mol / L CO(NH 2 ) 2 Then put the mixed solution immersed in the pretreated carbon cloth into the oven in the reaction kettle and heat it to 120°C for hydrothermal reaction for 12 hours. After natural cooling, cleaning and drying, the carbon cloth with pinkish purple solid on the surface is obtained. That is, the precursor of tricobalt tetroxide; after that, wash with absolute ethanol and distilled water, dry the precursor of tricobalt tetroxide at 60°C, and then put it into a tube furnace for roasting at a temperatur...

Embodiment 3

[0030] Reference attached figure 1 process, a Co 3 o 4 A preparation method for a nano-array superhydrophobic material coating, comprising the following steps:

[0031] (1) Synthesis of cobalt trioxide nanoarrays: Put the pretreated carbon cloth into 20mL CoCl with a concentration of 0.1mol / L after ultrasonic cleaning with acetone and absolute ethanol for 5min, and then wash and dry with distilled water 2 ·6H 2 O, 0.14mol / LNH 4 F and 0.18mol / L CO(NH 2 ) 2 Then put the mixed solution immersed in the pretreated carbon cloth into the oven in the reaction kettle and heat it to 140°C for hydrothermal reaction for 12 hours. After natural cooling, cleaning and drying, the carbon cloth with pinkish-purple solid on the surface is obtained. That is, the precursor of tricobalt tetroxide; after that, wash with absolute ethanol and distilled water, dry the precursor of tricobalt tetroxide at 60°C, and then put it into a tube furnace for roasting at a temperature of 360°C for 2 hours....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com