Application of trehalose as signal molecules in starch metabolism process of tobacco leaf baking process

A technology of metabolic processes and signal molecules, which can be used in applications, tobacco, tobacco preparation, etc., and can solve the problems of introducing microbial metabolites, affecting reducing sugar components, and affecting the quality and availability of tobacco leaves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

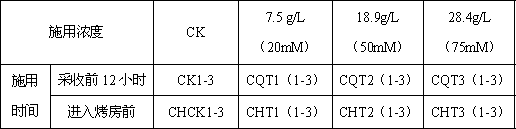

[0016] Field experiment: The variety was Zhongyan 100. 12 hours before harvest, 50 tobacco plants with good growth and consistent yellowing of the middle leaves (10th leaf position) were selected, sprayed at three concentrations, and the control was mixed with distilled water; Once after harvesting and before entering the curing barn, the tobacco field of the plot was selected as the sample the day before, 15 rods with the same degree of yellowing were selected, and the same three concentrations were used for leaf compounding, and distilled water was used for control.

[0017] Application concentration: 7.5 g / L; 18.9 g / L; 28.4 g / L three concentrations, corresponding to 20, 50, and 75 mM respectively.

[0018] Sampling: On the second day of baking (the temperature of the baking room is about 40℃), enter the baking room when the amylase activity is high, take a piece of tobacco from each rod, and after quick freezing in liquid nitrogen, bring it back to the laboratory to test the amyl...

example 2

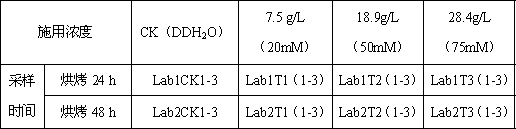

[0025] Laboratory experiment: The variety is China Tobacco 100, and the tobacco leaves are the upper part of the tobacco (the uppermost three pieces of tobacco). Choose 1,000 well-growing and consistent yellowing top leaf positions; transport them back to the laboratory as soon as possible after harvesting. Using the same three trehalose concentrations as in Example 1 plus a clear water control, 100 tobacco leaves (one tobacco clip) were treated for each concentration, three replicates, and the control treated with the same amount of distilled water, three replicates. After the treatment is completed, use a small laboratory oven to bake in three stages. Samples were taken at 24 h and 48 h after baking. The amylase activity was measured after quick freezing in liquid nitrogen. After the baking, the cured tobacco was taken to determine the starch and reduction. Sugar content.

[0026] Table 4 Laboratory experiment of trehalose reducing starch in tobacco leaves

[0027]

[0028] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com