Cold-rolled non-oriented silicon steel low in iron loss and production method

A technology of oriented silicon steel and low iron loss, applied in the field of low iron loss cold-rolled non-oriented silicon steel and production, can solve the problems of complex process, reduced yield, and thick steel plate thickness, and achieves economical process, reduced iron loss, and yield of finished products. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in detail below:

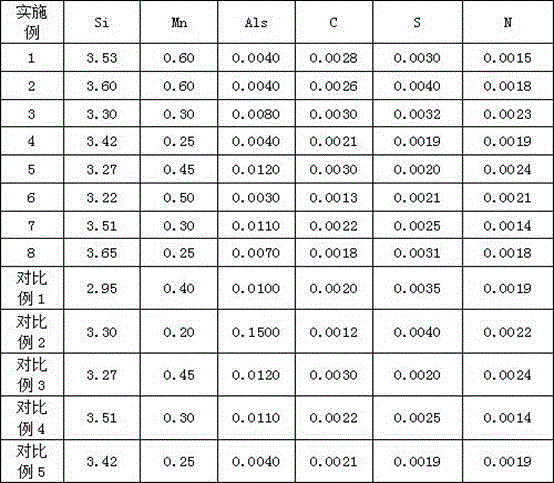

[0035] Table 1 is each embodiment of the present invention and comparative example composition value list;

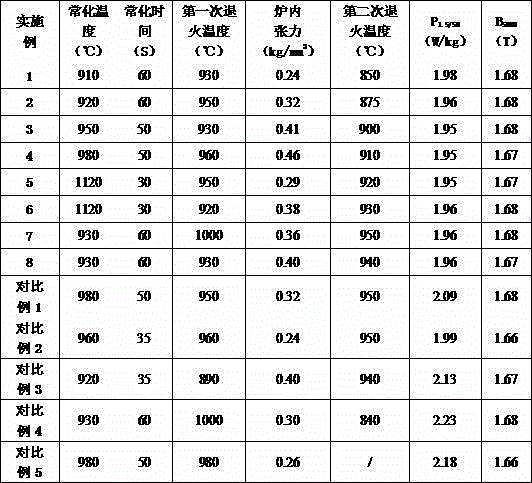

[0036] Table 2 is a list of main process parameters and corresponding magnetic properties of each embodiment and comparative example of the present invention.

[0037] Each embodiment of the present invention is produced according to the following steps:

[0038] 1) Steelmaking, vacuum smelting and continuous casting into billets;

[0039] 2) Heating the slab, the heating temperature is controlled at 1050-1150°C, and the holding time is controlled at 60-120min;

[0040] 3) Carry out hot rolling, and control the finishing rolling temperature at 800-900°C;

[0041] 4) Carry out normalization, the normalization temperature is controlled at 900-1150°C, and the normalization time is controlled at 20-150s;

[0042] 5) After conventional pickling, it is cold-rolled and rolled to a finished product thickness of 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com