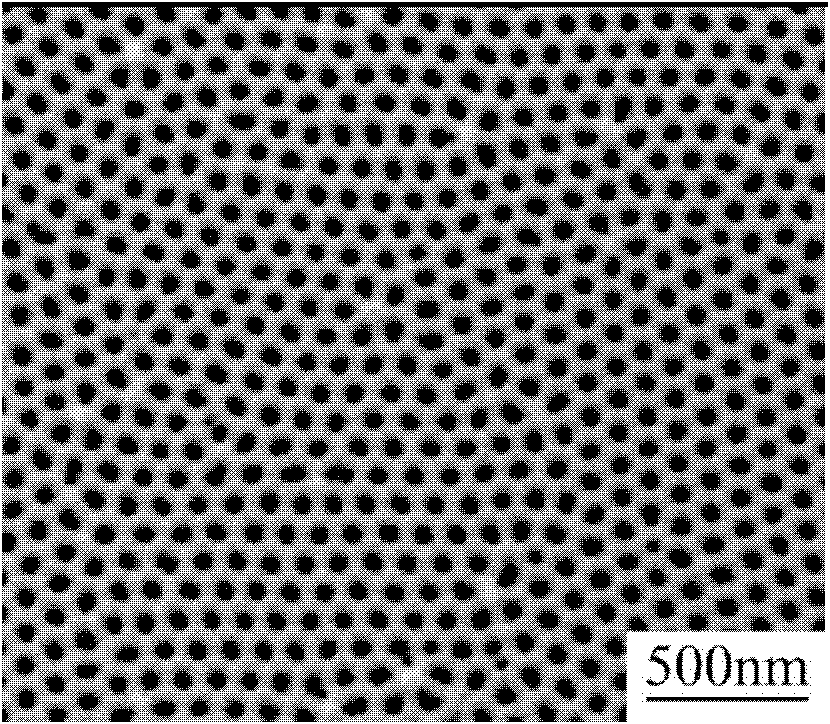

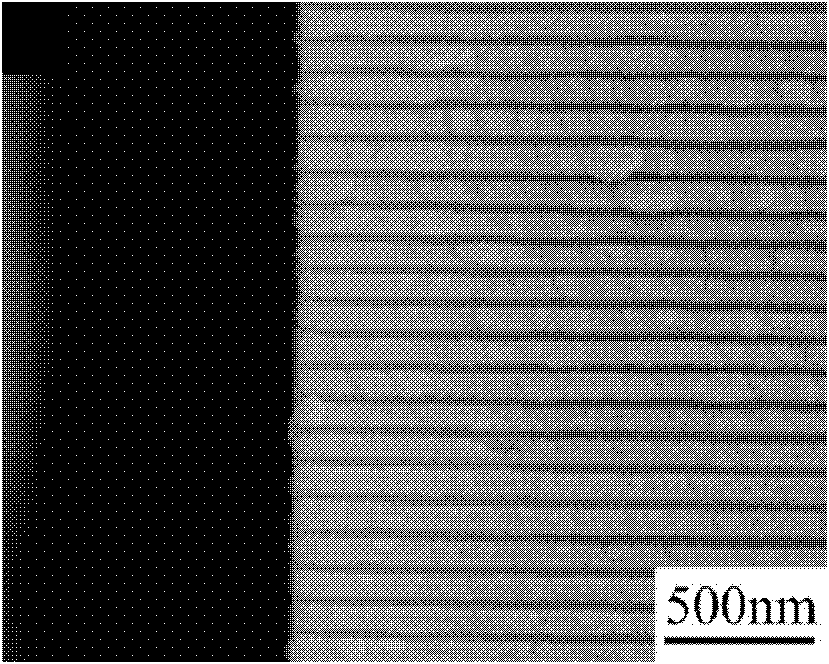

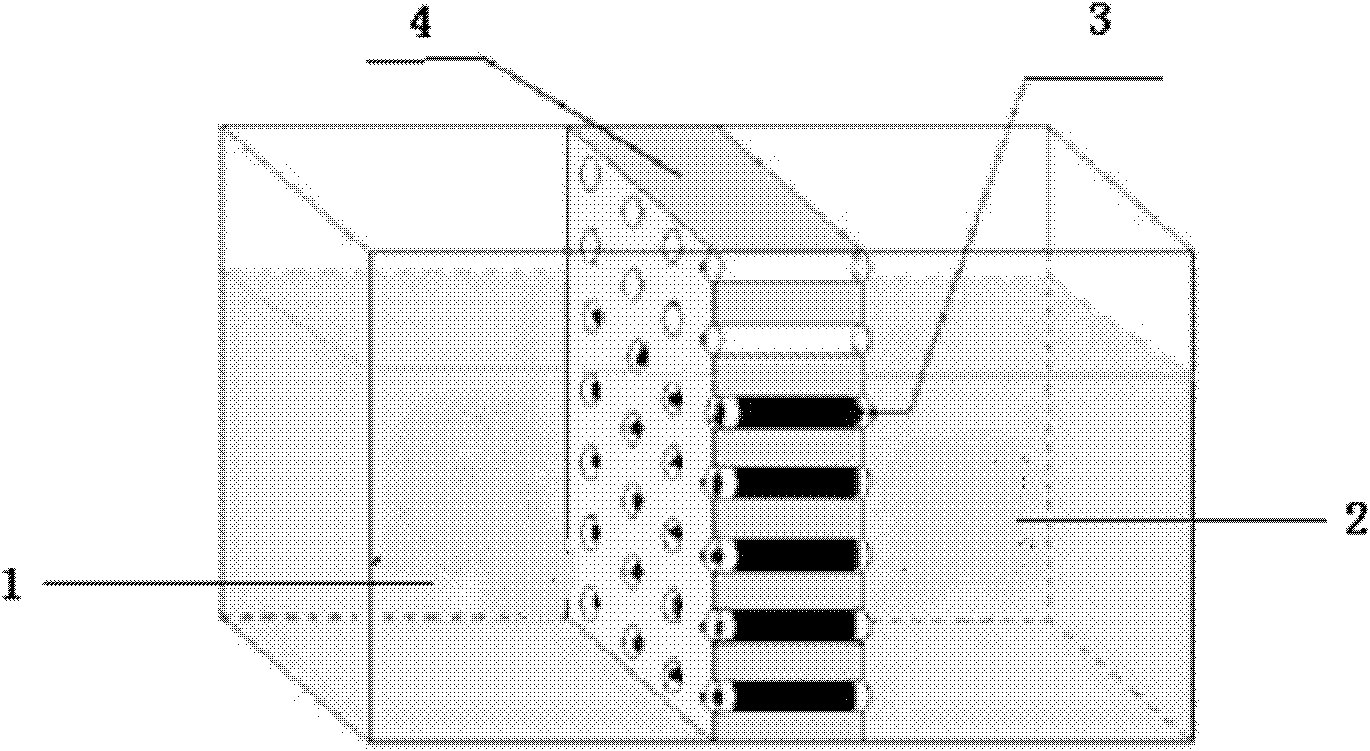

Method for preparing silver nanowire array in ordered porous alumina template

A technology of porous alumina and alumina templates, which is applied in the field of preparing silver nanowire arrays, can solve the problems of high requirements for experimental equipment, high cost, and difficult control of experimental conditions, and achieve low requirements for experimental equipment, simplified preparation process, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Annealing: Anneal the high-purity aluminum sheet with a purity ≥ 99.99%, hold it at 500°C for 5 hours to eliminate the stress caused by the shearing of the aluminum sheet, and take it out after cooling to room temperature with the furnace.

[0041] 2. Ultrasonic cleaning: immerse the annealed aluminum sheet in pure acetone, ethanol and deionized water in sequence, and ultrasonically clean it for 3 minutes respectively to remove stains on the aluminum surface.

[0042] 3. Remove the natural oxide film: immerse the cleaned aluminum sheet in an 8% NaOH solution (at a constant temperature of 60° C.) for 2 minutes, then take it out and clean it with deionized water to remove the natural oxide film.

[0043] 4. Electrochemical polishing: put the aluminum sheet on the electrolytic device (the anode is connected to the aluminum sheet), and immerse in the electropolishing solution (95vol%H 3 PO 4 (85%)+5vol%H 2 SO 4 (97%)+20g / L CrO 3 ), and use a stirring device to stir t...

Embodiment 2

[0059] 1. Annealing: Anneal the high-purity aluminum sheet with a purity ≥ 99.99%, hold it at 500°C for 5 hours to eliminate the stress caused by the shearing of the aluminum sheet, and take it out after cooling to room temperature with the furnace.

[0060] 2. Ultrasonic cleaning: immerse the annealed aluminum sheet in pure acetone, ethanol and deionized water in sequence, and ultrasonically clean it for 3 minutes respectively to remove stains on the aluminum surface.

[0061] 3. Remove the natural oxide film: immerse the cleaned aluminum sheet in an 8% NaOH solution (at a constant temperature of 60° C.) for 2 minutes, then take it out and clean it with deionized water to remove the natural oxide film.

[0062] 4. Electrochemical polishing: put the aluminum sheet on the electrolytic device (the anode is connected to the aluminum sheet), and immerse in the electropolishing solution (95vol%H 3 PO 4 (85%)+5vol%H 2 SO 4 (97%)+20g / L CrO 3 ), and use a stirring device to stir t...

Embodiment 3

[0071] 1. Annealing: Anneal the high-purity aluminum sheet with a purity ≥ 99.99%, hold it at 500°C for 5 hours to eliminate the stress caused by the shearing of the aluminum sheet, and take it out after cooling to room temperature with the furnace.

[0072] 2. Ultrasonic cleaning: immerse the annealed aluminum sheet in pure acetone, ethanol and deionized water in sequence, and ultrasonically clean it for 3 minutes respectively to remove stains on the aluminum surface.

[0073] 3. Remove the natural oxide film: immerse the cleaned aluminum sheet in an 8% NaOH solution (at a constant temperature of 60° C.) for 2 minutes, then take it out and clean it with deionized water to remove the natural oxide film.

[0074] 4. Electrochemical polishing: put the aluminum sheet on the electrolytic device (the anode is connected to the aluminum sheet), and immerse in the electropolishing solution (95vol%H 3 PO 4 (85%)+5vol%H 2 SO 4 (97%)+20g / L CrO 3 ), and use a stirring device to stir t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com