Numerical control machining process design system and method of aircraft complex components facing process object

A technology of processing technology and process design, which is applied in the field of computer-aided design system of numerical control processing technology of aircraft complex components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

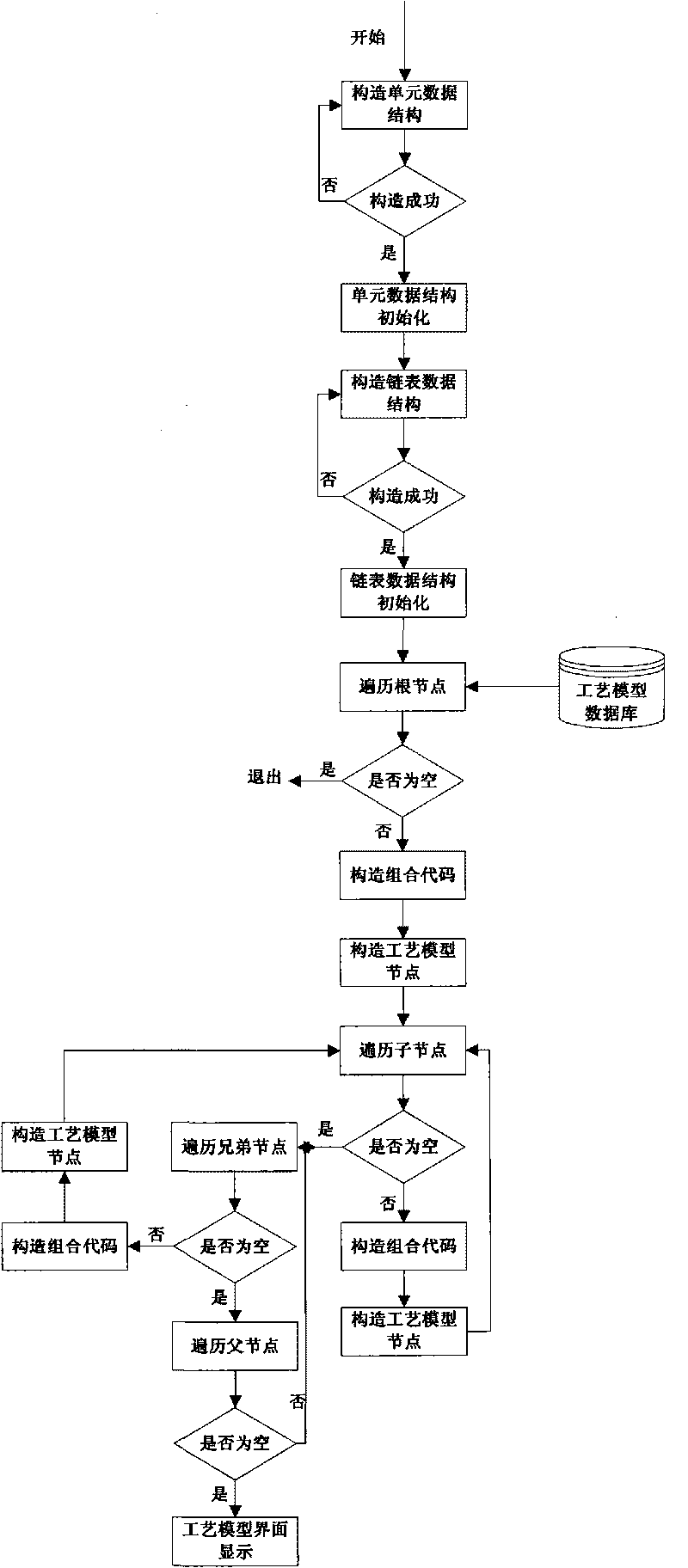

[0094] The implementation process of the present invention will be described in detail below in conjunction with the accompanying drawings.

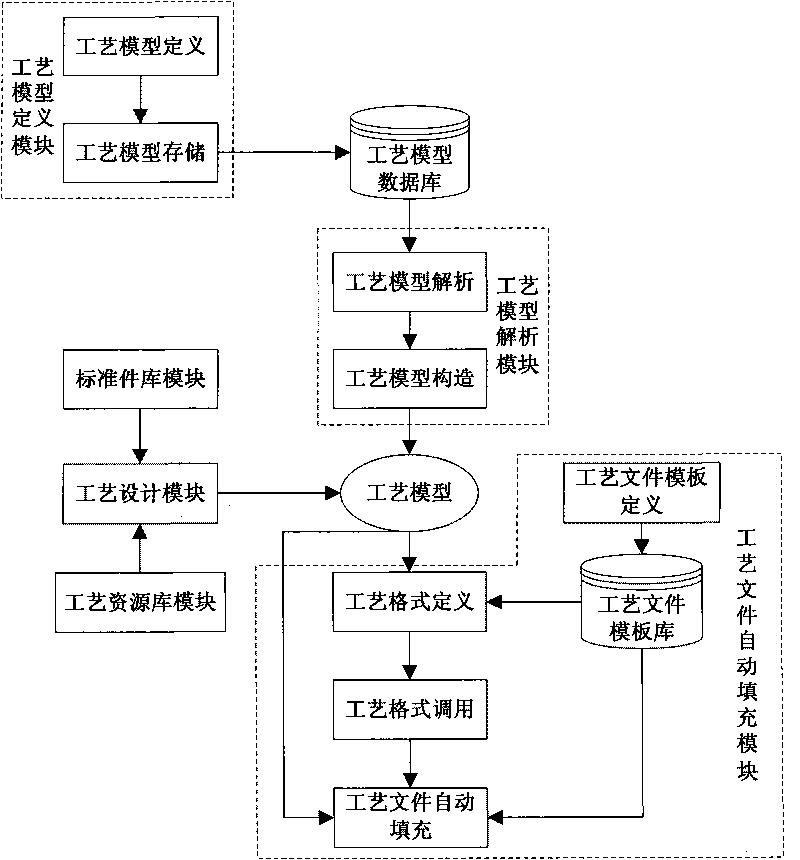

[0095] Such as figure 1 As shown, a technology object-oriented NC machining process design system for aircraft complex components, including:

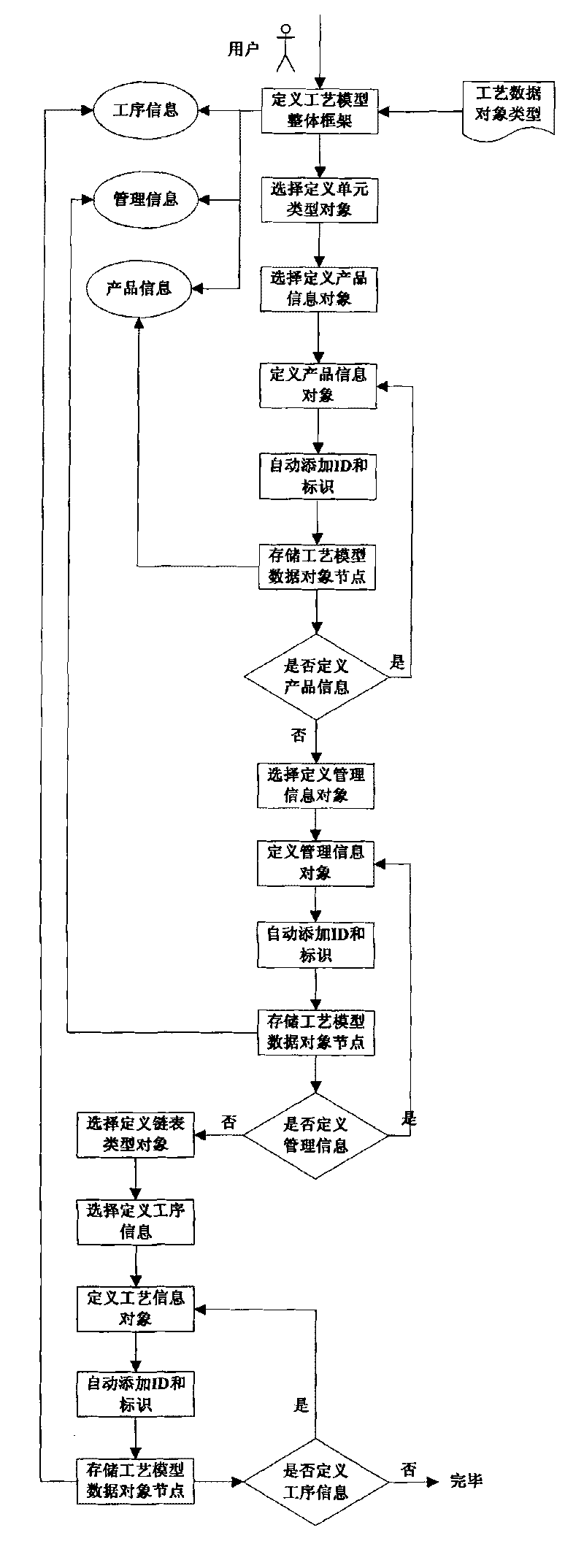

[0096] Process model definition module: define the process model according to the process data objects designed in the process design process, and build a process model database to store and manage process model data in a unified manner; specifically, the process model definition module is to complete the manufacturing process of product parts or components, etc. Process data, as well as auxiliary information for production management and process statistics are summarized, abstracted and analyzed to form data objects for product parts or component process design. Parts contain (1) part information, such as part name, code, quantity, drawing (2) Management information, such as document number, cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com