Compressor

a compressor and liquefied natural gas technology, applied in the direction of positive displacement liquid engines, container discharging methods, lighting and heating apparatuses, etc., can solve the problems of large motors and substantial power consumption, and achieve the effect of reducing size and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

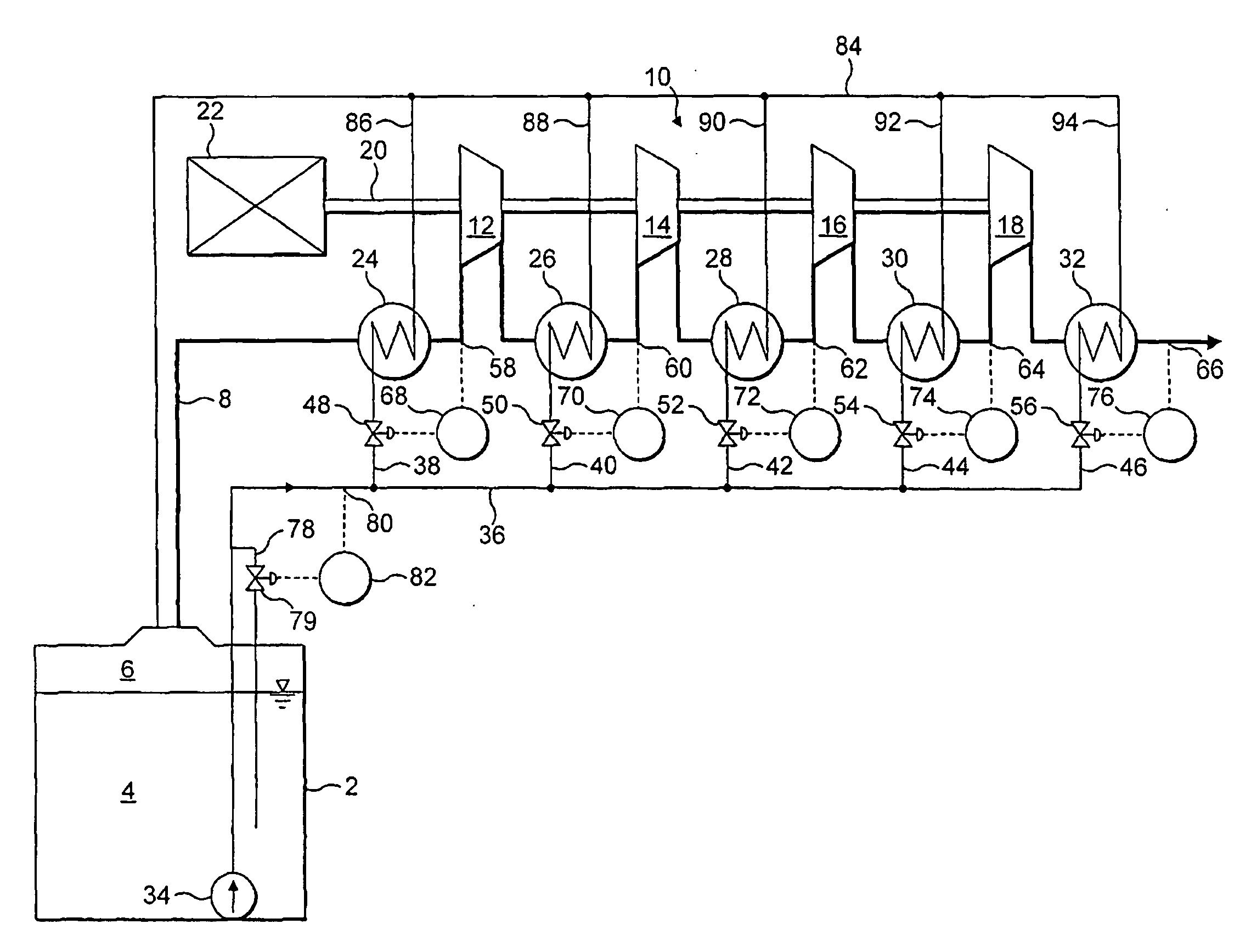

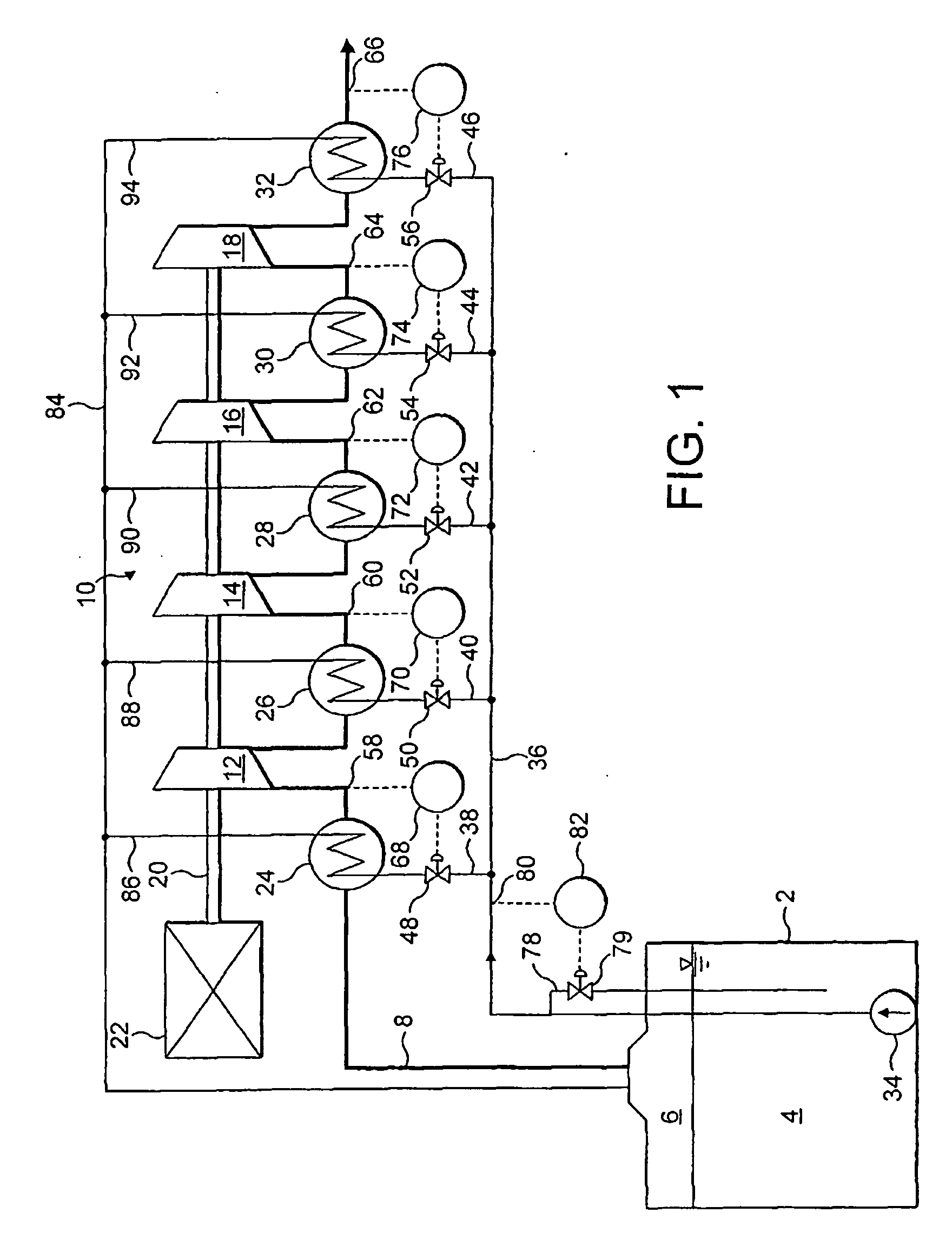

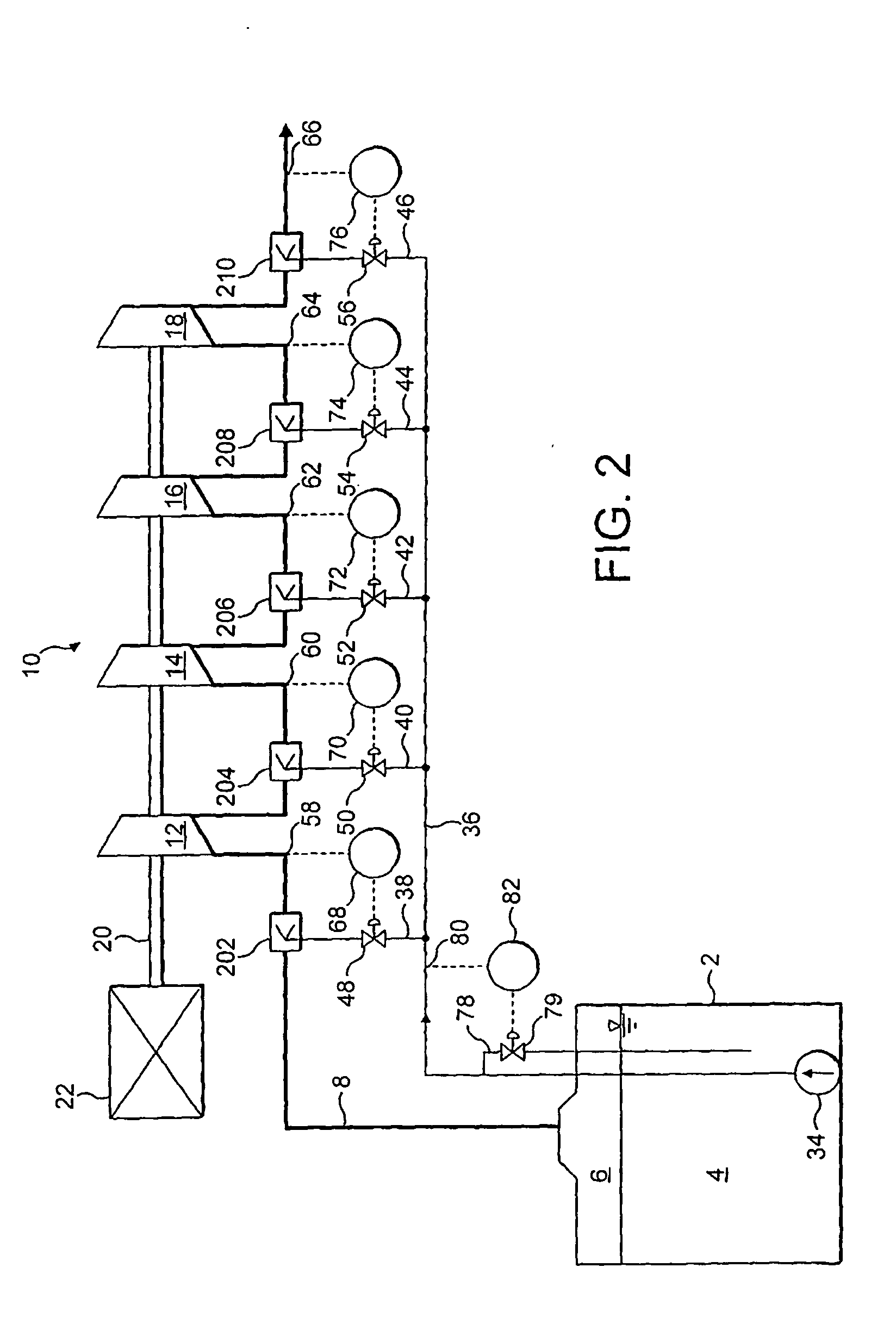

[0019]Referring to FIG. 1 of the drawings, there is shown an LNG storage tank 2. For the purposes of ease of illustration, various pipes and valves associated with the tank 2, for example, its fill pipe and its LNG discharge pipe, are not shown in FIG. 1 and the other drawings. The configuration and operation of such LNG tanks is however well known in the art. The tank 2 is typically located on board an ocean-going tanker (not shown). The tank 2 is shown containing a volume 4 of LNG. There is an ullage space 6 above the surface of the volume 4 of LNG in the tank 2. The tank 2 is vacuum-insulated or has another form of thermal insulation associated therewith so as to keep down the rate of flow of heat from the ambient environment into the liquid 4. Since LNG boils at a cryogenic temperature, notwithstanding the thermal insulation of the tank 2, there is continuous adsorption of heat by the LNG from its surroundings and hence continuous evaporation of the LNG into the ullage space 6. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com