Liquid and compressed natural gas dispensing system

a liquid and compressed natural gas technology, applied in the direction of container filling under pressure, container discharging methods, packaged goods types, etc., can solve the problems of inefficient liquid filling of multiple tanks, insufficient cooling and pressurizing, and insufficient cooling of cascades, etc., to achieve the effect of reducing the time of cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

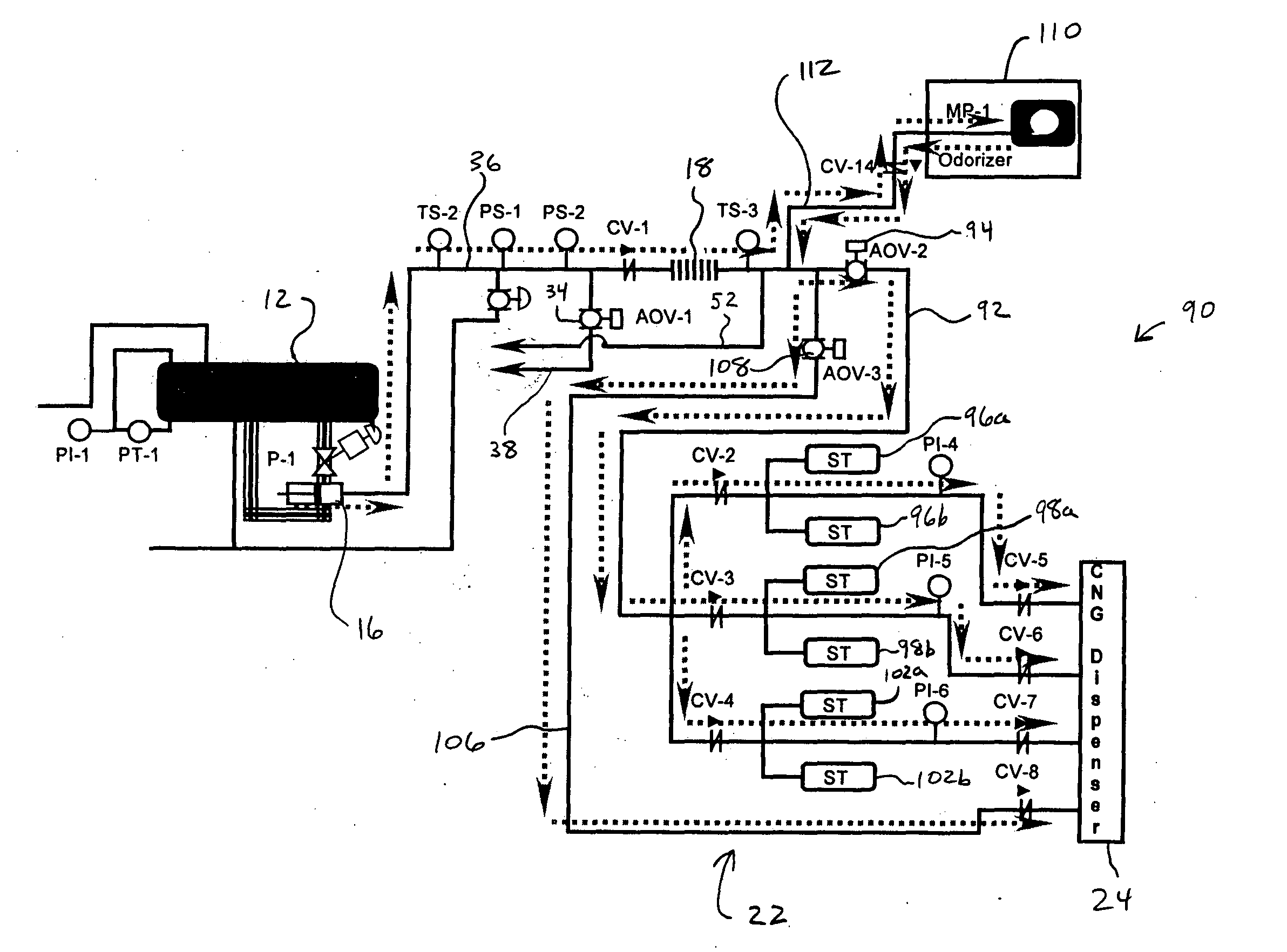

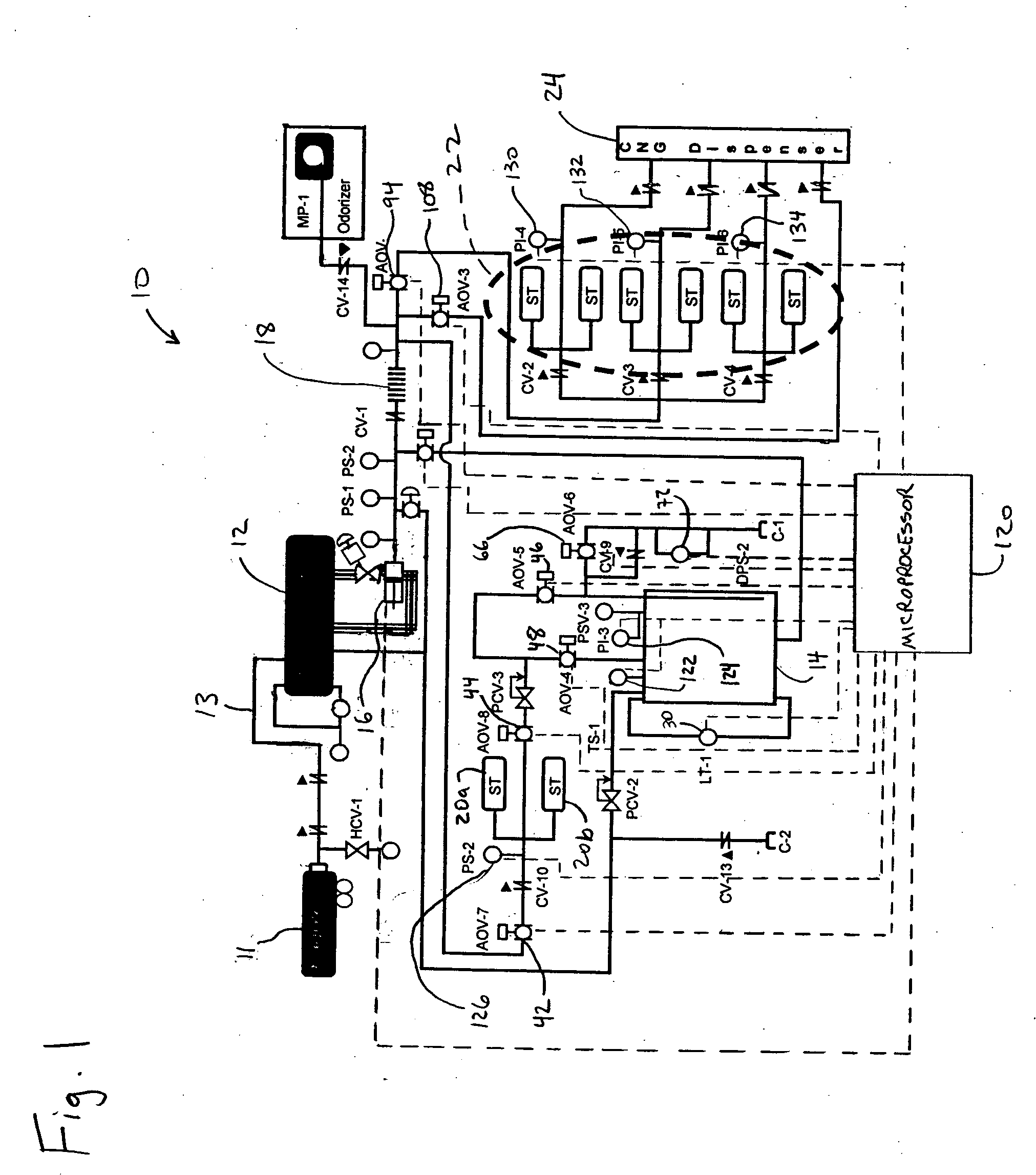

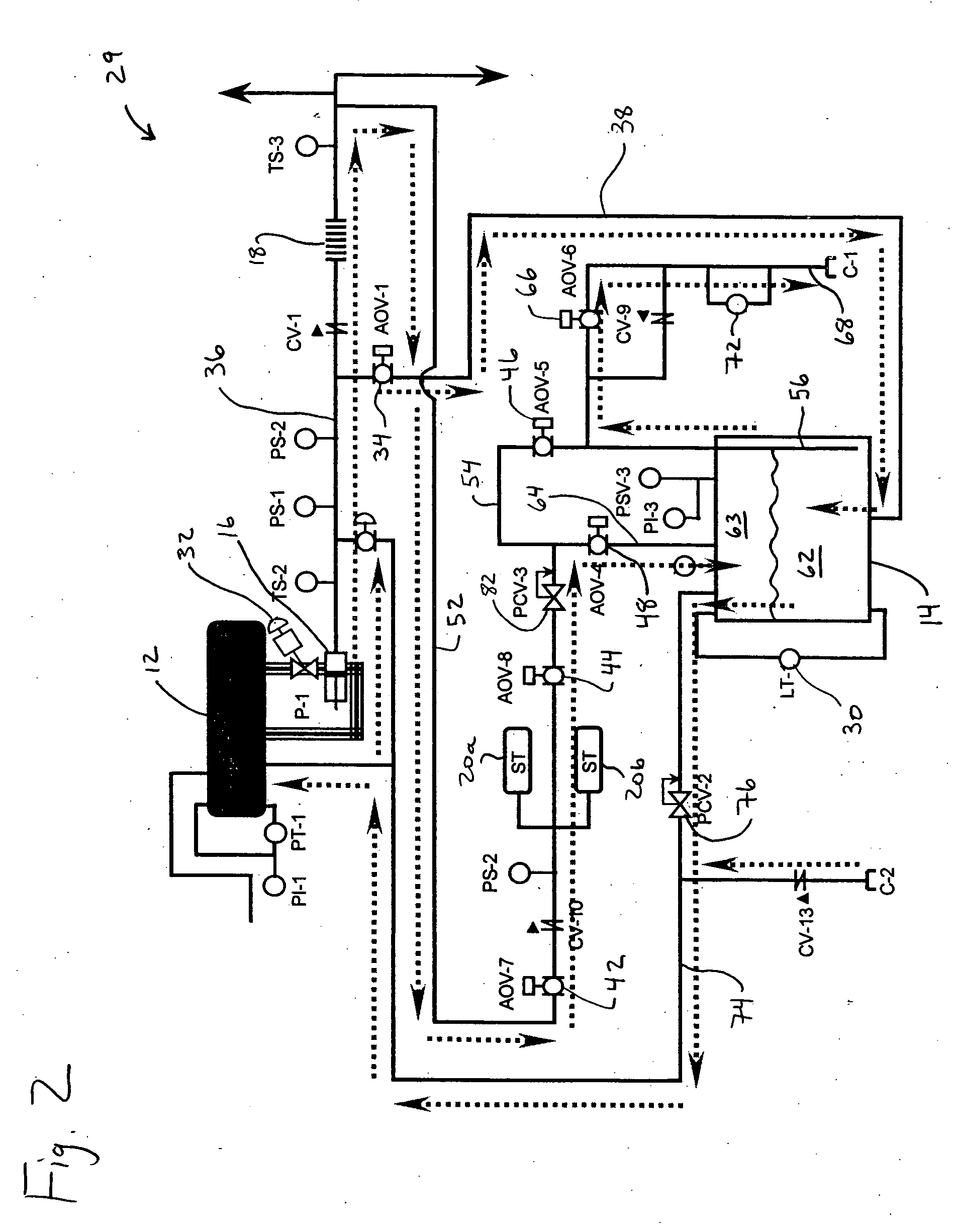

[0027] An embodiment of the system of the present invention is indicated in general at 10 in FIG. 1. The system 10 is self-contained and dispenses liquid natural gas (LNG) and compressed natural gas (CNG) from a horizontal cryogenic bulk tank, indicated at 12, at sites where limited height requirements are an issue. The system, including the bulk tank 12, may be housed, for example, within a 40 foot ISO container and thus may be rapidly installed at a site either temporarily or permanently. The system, as explained below, may also be easily automated.

[0028] While the system of the present invention is described below in terms of dispensing CNG and LNG to vehicles, it could alternatively be used dispense other types of cryogenic fluids to other types of use devices.

[0029] The bulk tank 12 of the system 10 preferably has a capacity of approximately 5000 gallons for storing LNG. It may be refilled by a transport 11 carrying a supply of LNG through line 13. The system 10 also includes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com