Alloy filling device for pipe bending and filling method thereof

An alloy and pipe bending technology, which is applied in the field of equipment for pipe bending, can solve the problems of easy separation of pipes and low-temperature alloys, large solidification shrinkage of low-temperature alloys, and easy fracturing of pipe bends, so as to achieve small bending deformation and waste pipe bends. The effect of low rate and difficult separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

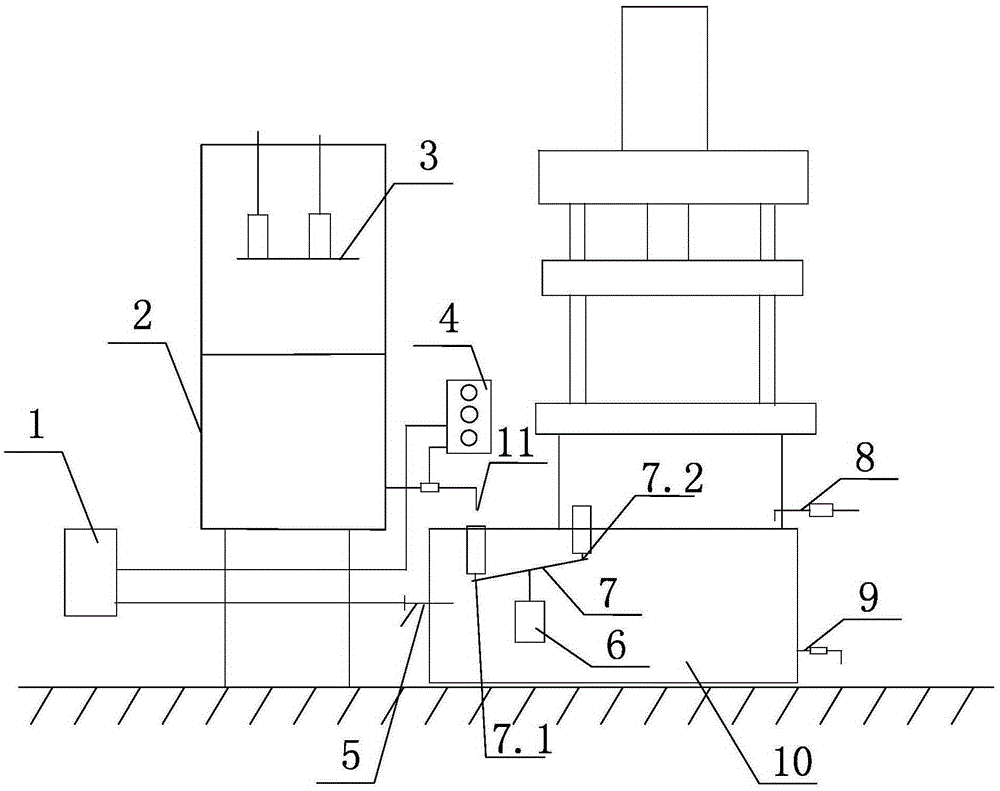

[0015] like figure 1 As shown, an elbow filling alloy device includes a control system 1, a low-temperature alloy molten pool 2, an alloy filling device, a water bath device including a water bath 10 whose water temperature is controlled at 30-35°C, an indexing workbench 7 and a pressure machine, the alloy filling device includes a connecting pipe connected to the bottom of the molten alloy pool and a discharge port 11, and the discharge port 11 is electrically connected to the control system 1 and used to control the flow rate of the low-temperature alloy Switch 4, the indexing table 7 is arranged obliquely, and the angle between the plane where the indexing table 7 is located and the horizontal direction is 15° to 30°, and the indexing table 7 is driven by the motor 6 Drive rotation; the indexing table 7 is provided with a plurality of stations for pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com