Filling device for emulsion explosive production

An emulsion explosive and filling device technology, applied in explosives, explosives processing equipment, offensive equipment and other directions, can solve the problems of poor filling safety and stability of emulsion explosives, and achieve the goal of improving blasting safety and stability, reducing damage and reducing extrusion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

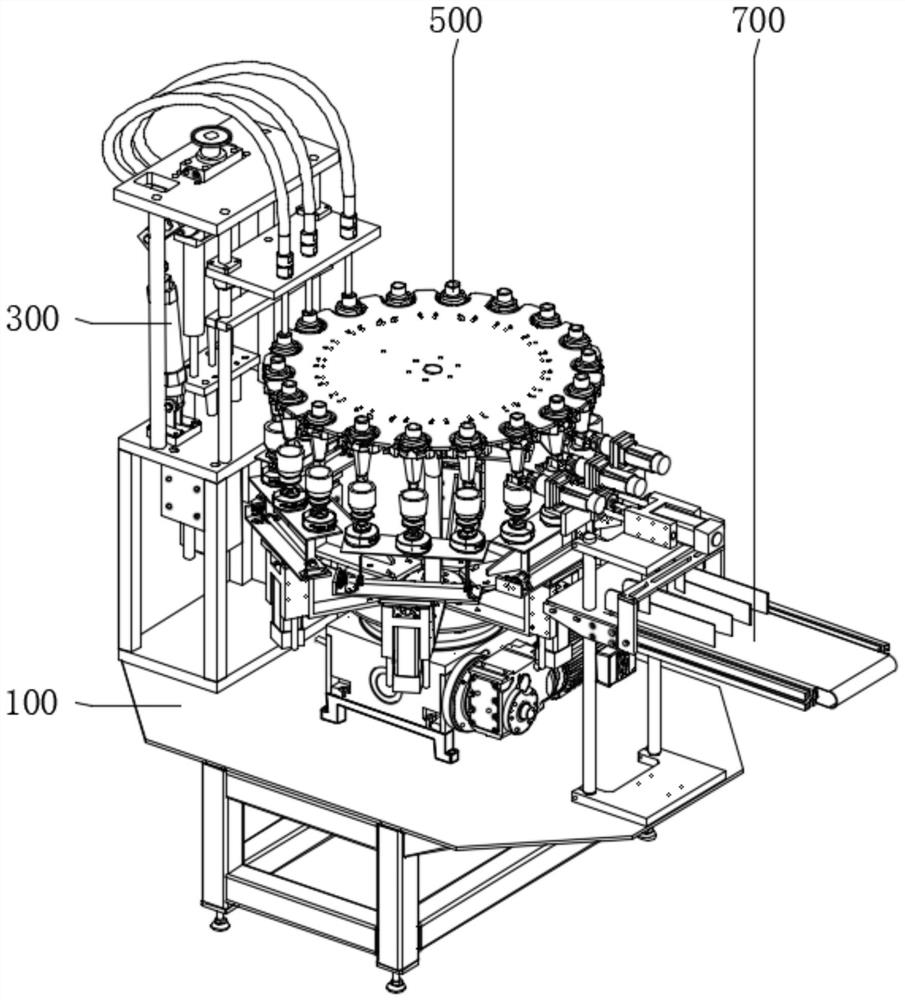

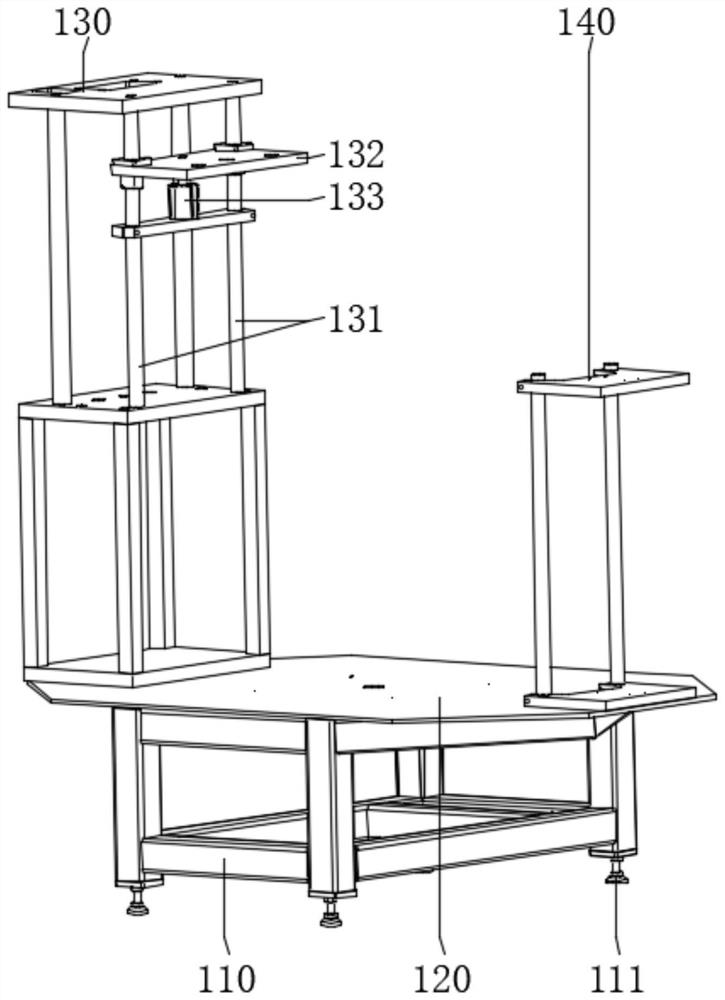

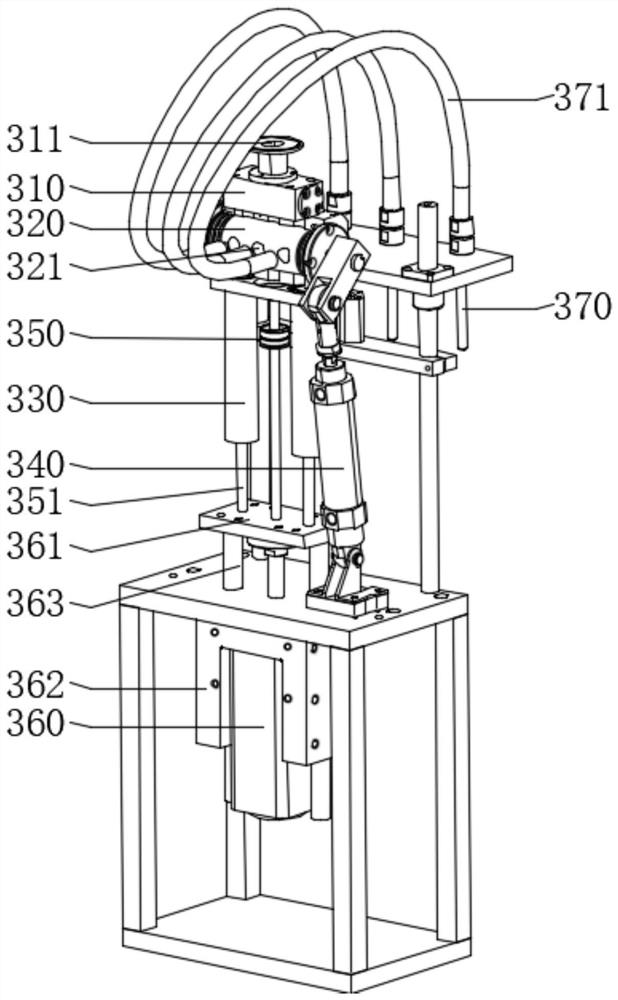

[0040] see figure 1 , the present invention provides a technical solution: the filling device for emulsion explosive production includes a support assembly 100, a filling assembly 300, a packaging assembly 500 and a discharge assembly 700, the filling assembly 300 is installed on one side of the support assembly 100, and the discharge assembly 700 is installed on the other side of the support assembly 100, and the packaging assembly 500 is installed between the filling assembly 300 and the discharge assembly 700. The support assembly 100 supports the filling device, and the filling assembly 300 accurately and seamlessly measures the emulsion explosive through piston metering. Squeeze filling, the packaging component 500 performs automatic sealing and automatic process rotation transportation on the upright plastic film drug roll, and the discharge component 700 performs vacuum upright adsorption on the plastic film drug roll and turns it over for transportation.

[0041] see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com