Filling method of phase-change material in phase-change heat pipe

A phase change material and heat pipe technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of tube shell burst, failure to meet design requirements, melting of phase change materials, etc., to ensure safety and reliability. , The effect of reducing the fluid damping coefficient and increasing the filling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

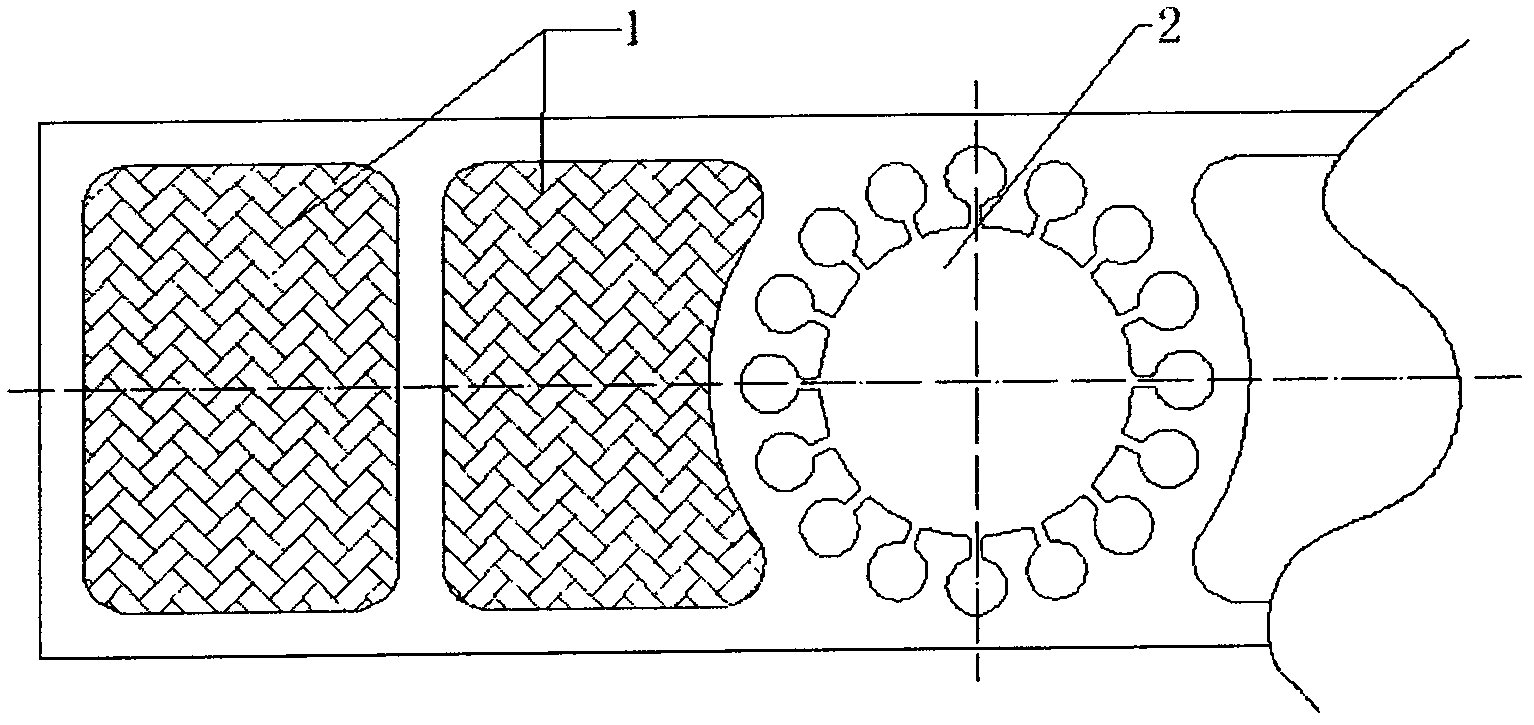

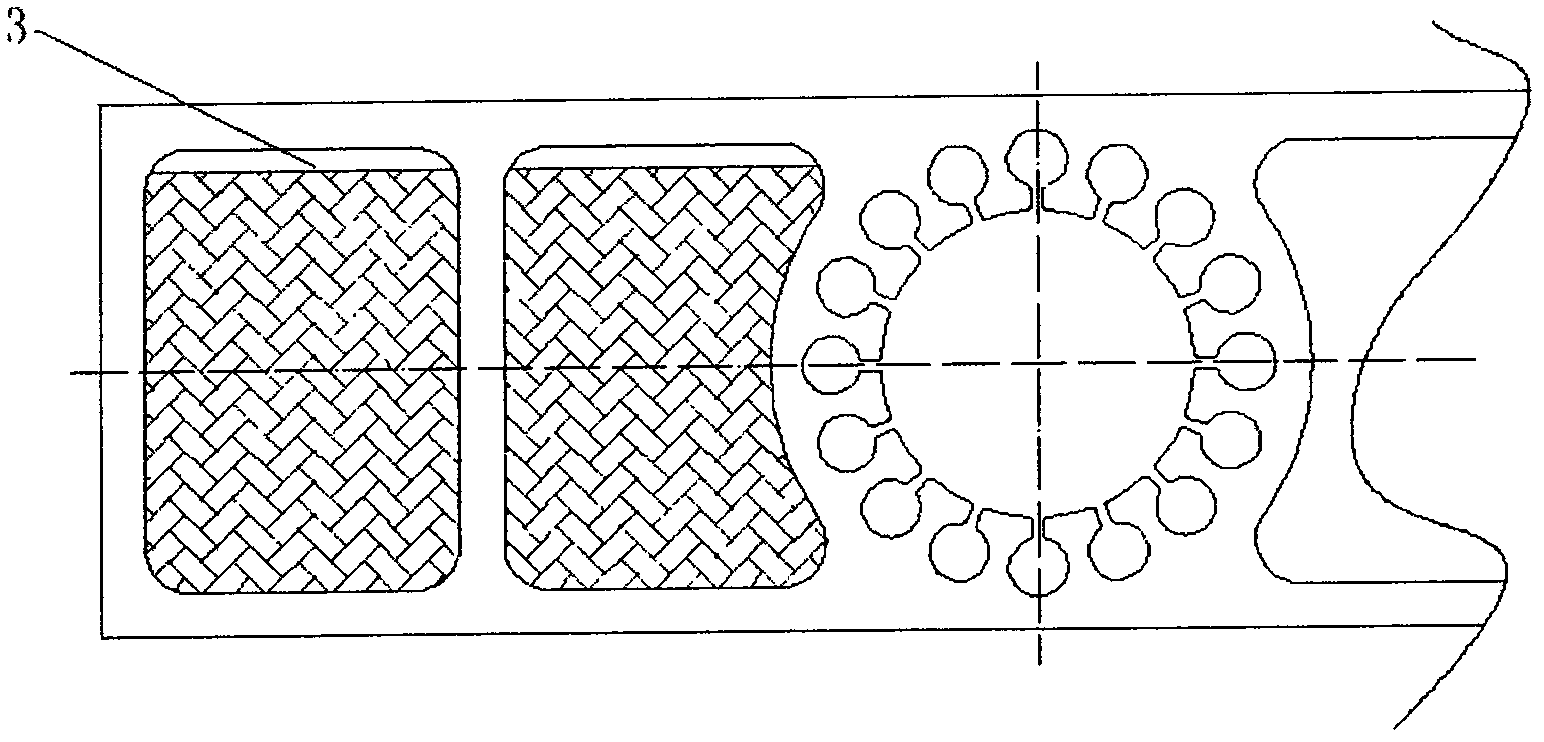

[0012] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments. These examples should be understood as only for illustrating the present invention but not for limiting the protection scope of the present invention. After reading the contents of the present invention, those skilled in the art can make various changes or modifications to the present invention, and these equivalent changes and modifications also fall within the scope defined by the claims of the present invention.

[0013] The new filling method of the phase change material of the phase change heat pipe provided by the preferred embodiment of the present invention, the phase change material is 18 alkane, on the basis of the traditional filling method, the temperature of the phase change material during filling is increased to reach above 90°C . When filling, the phase change material is already in a liquid state, and the filling can be complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com