A closed low filling rate parallel tank filling method

A filling rate and closed technology, which is applied in the pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as inability to accurately fill storage tanks, affect the balanced discharge of parallel storage tanks, and deflection of the center of mass of satellites. Achieve the effects of simple filling method, safe and reliable filling process, and reasonable filling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only some structures related to the present invention are shown in the drawings but not all structures.

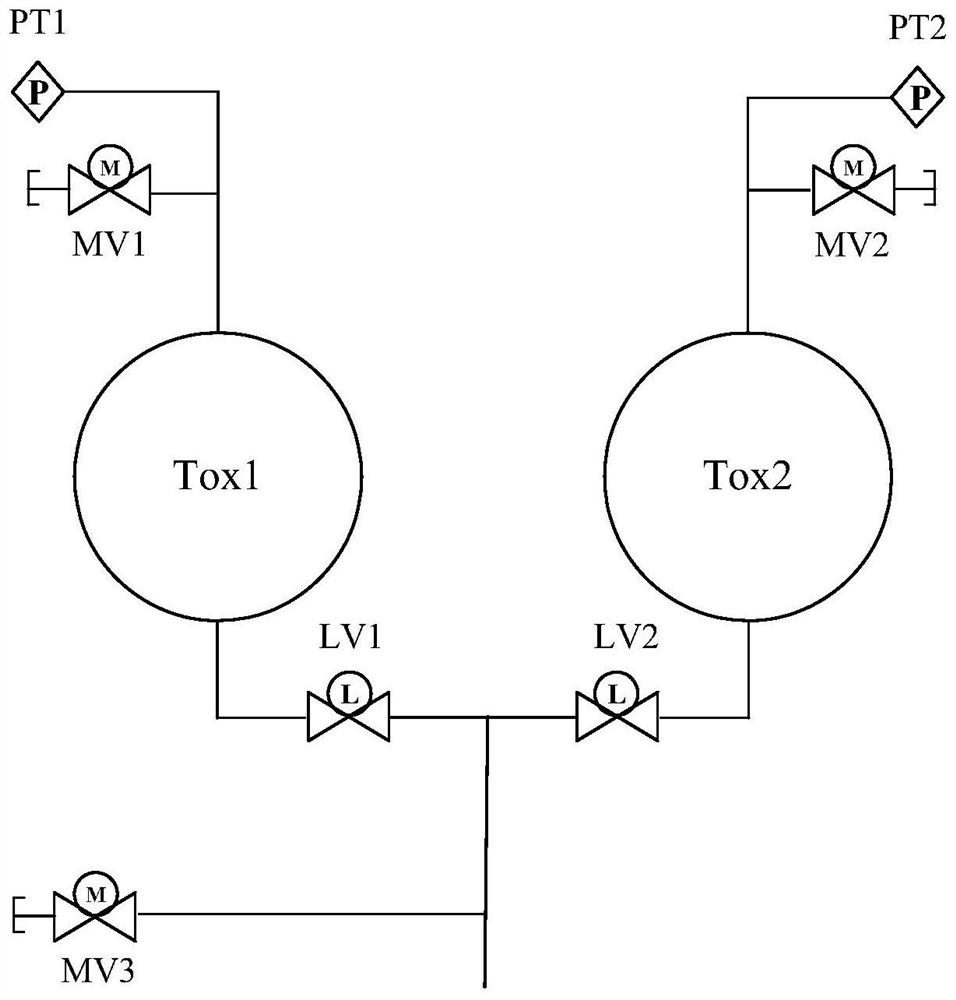

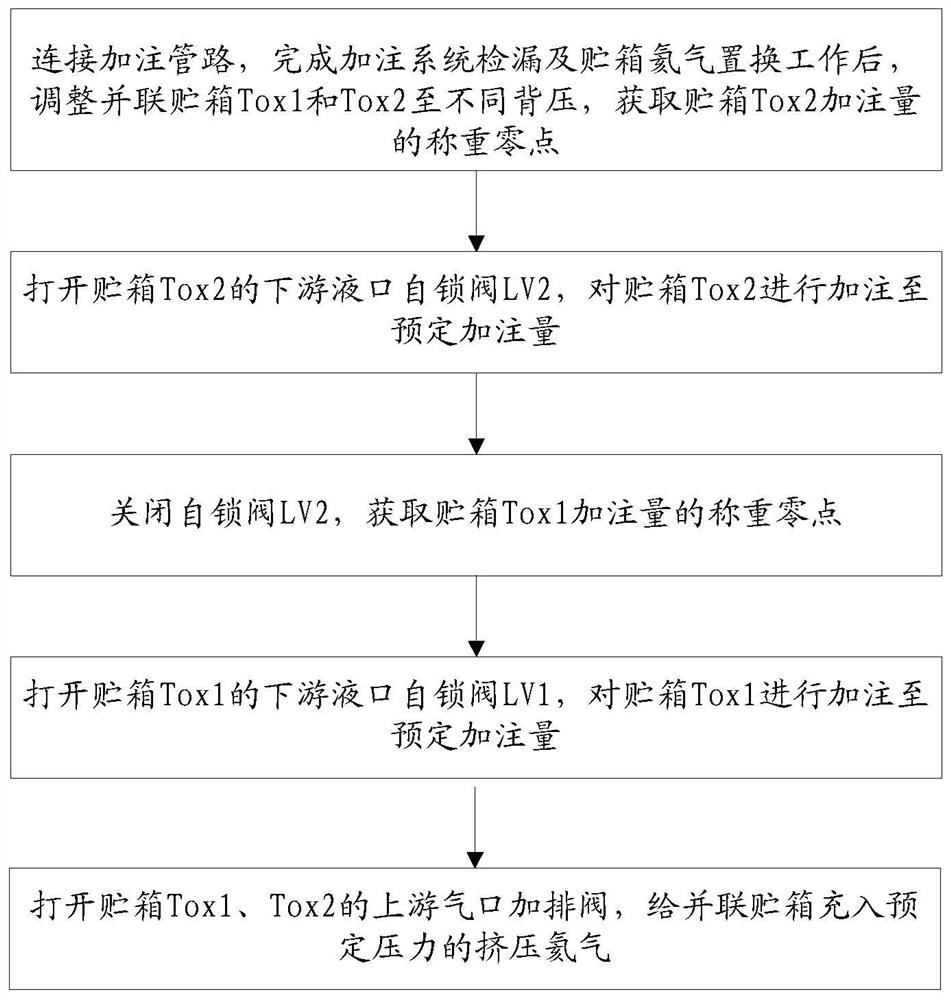

[0030] figure 1 is a structural diagram of the parallel storage tank system in the embodiment of the present invention, such as figure 1 As shown, a typical parallel tank system structure consists of 2 propellant tanks (Tox1 and Tox2), 3 filling and discharging valves (MV1, MV2 and MV3), 2 pressure sensors (PT1 and PT2) and 2 self-locking valves (LV1 and LV2).

[0031] Tanks Tox1 and Tox2 both include air inlet and outlet and liquid inlet and outlet, the air inlet and outlet are located at the top, and the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com