A kind of multi-color bulk powder molding machine and molding method

A molding machine and block technology, applied in the direction of material molding presses, presses, manufacturing tools, etc., can solve the problems of large deviation, flying dust net content, etc., to achieve stable net content, maintain environmental hygiene, and avoid damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

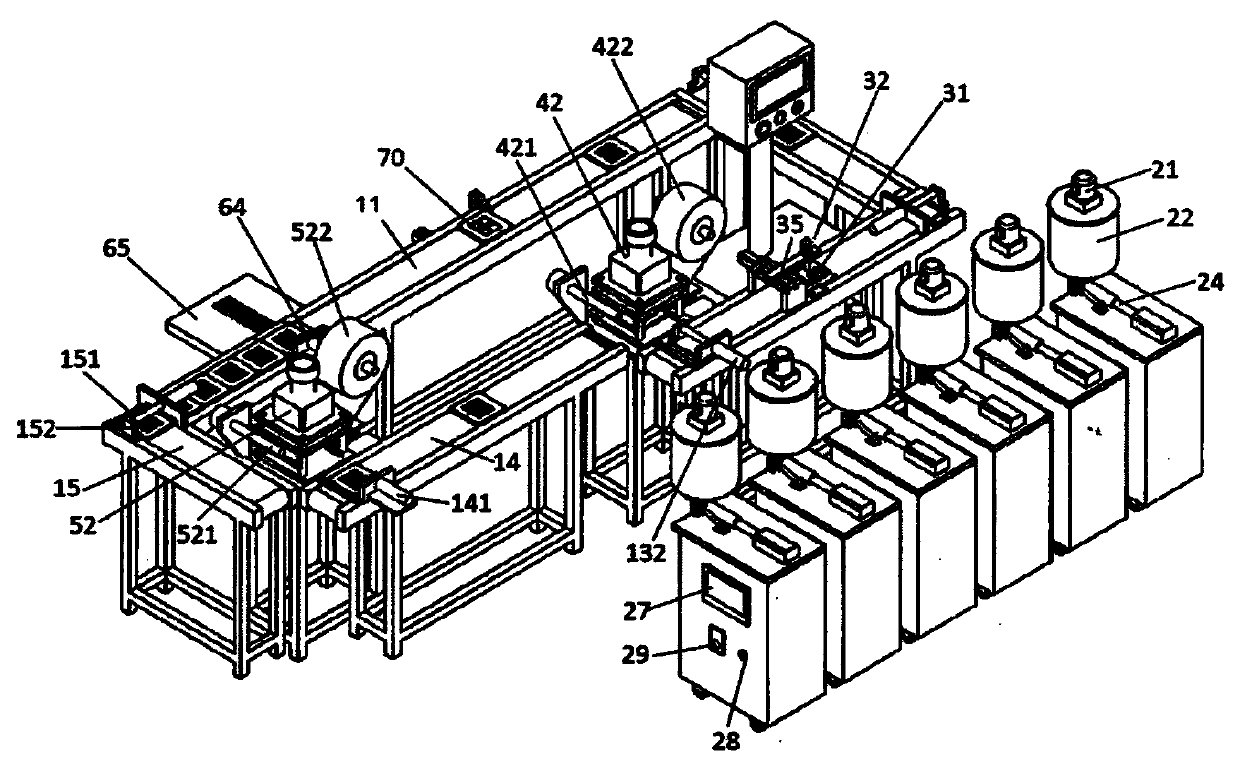

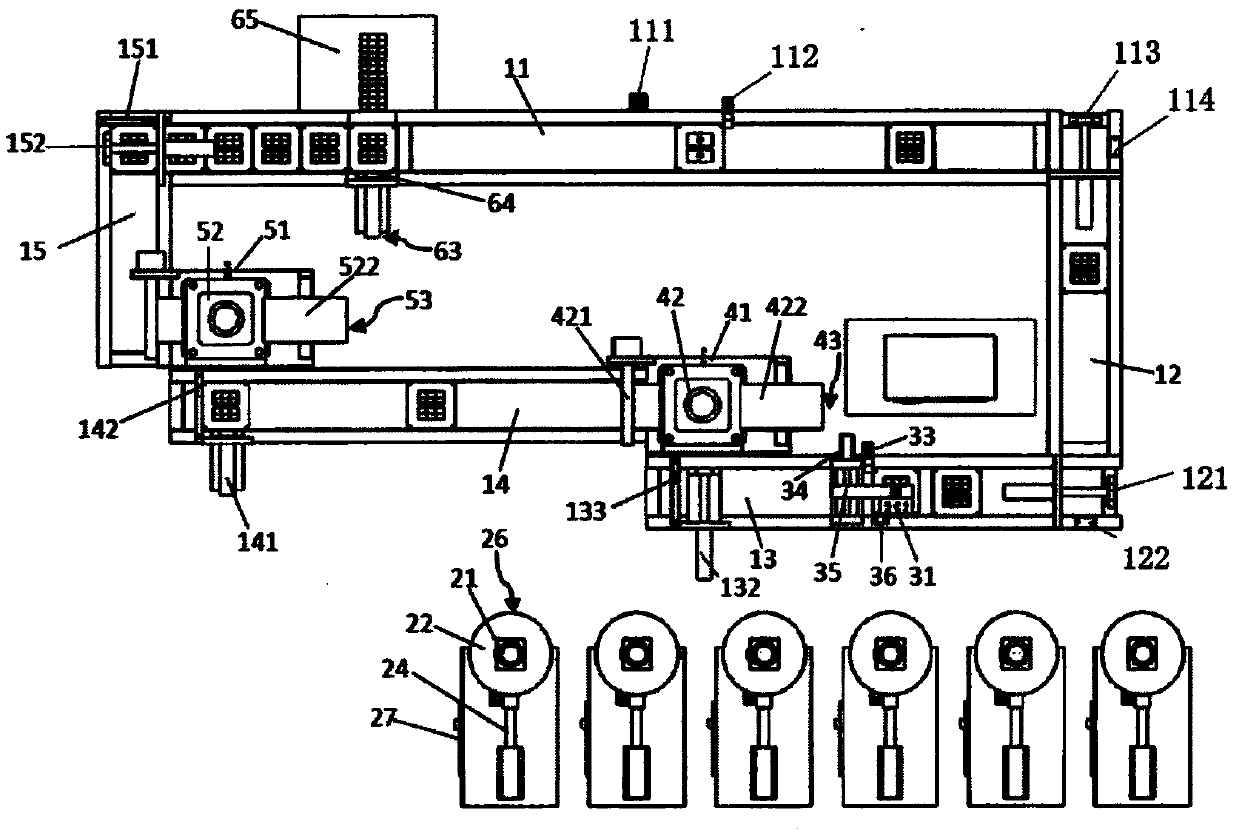

[0055] like figure 1 and figure 2 Shown, multi-color bulk powder molding machine of the present invention comprises:

[0056] A conveyor system, which includes 5 conveyor belts, capable of sequentially conveying the bottom mold carrying the inner tray to the filling unit, the initial pressure unit, the final pressure unit and the product output unit;

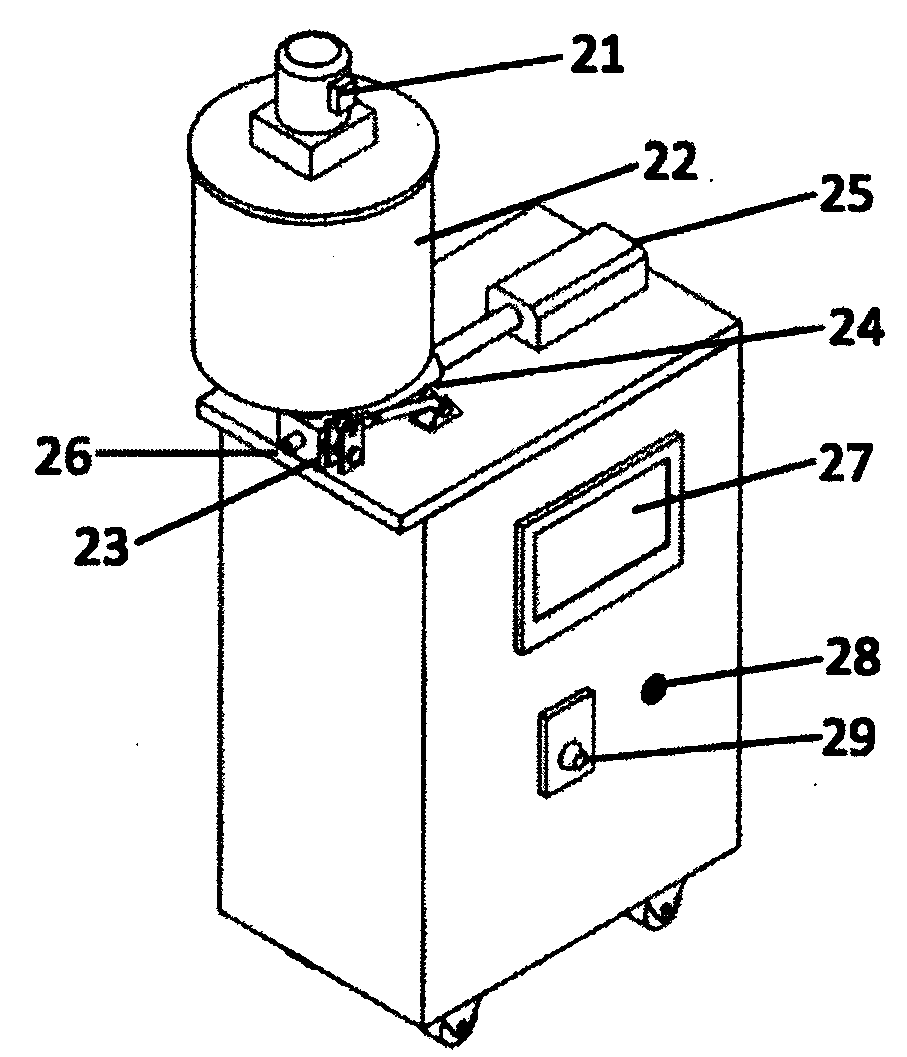

[0057] A filling unit, which includes 6 filling hosts capable of filling materials of different colors into the filling unit;

[0058] A filling unit, which can simultaneously fill materials of 6 different colors into the inner tray;

[0059] An initial pressing unit, which can initially press the material in the inner tray into multi-color block powder;

[0060] A final pressing unit, used to further press the multi-color block powder in the inner tray;

[0061] And a product output unit, used for outputting the inner tray filled with multi-color block powder.

[0062] Described conveying system comprises 5 conveyer belts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com