A water-cooled inverter ultra-pure coolant filling storage filling device and filling method

A filling device and cooling liquid technology, applied in bottle filling, liquid bottling, using back pressure filling, etc., can solve the problem that the conductivity cannot ensure that the cooling water is not polluted by the air, it is inconvenient to move, and the resistance and insulation of the cooling liquid are reduced To achieve the effect of changing the way of one-time use, ensuring that the quality does not change, and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

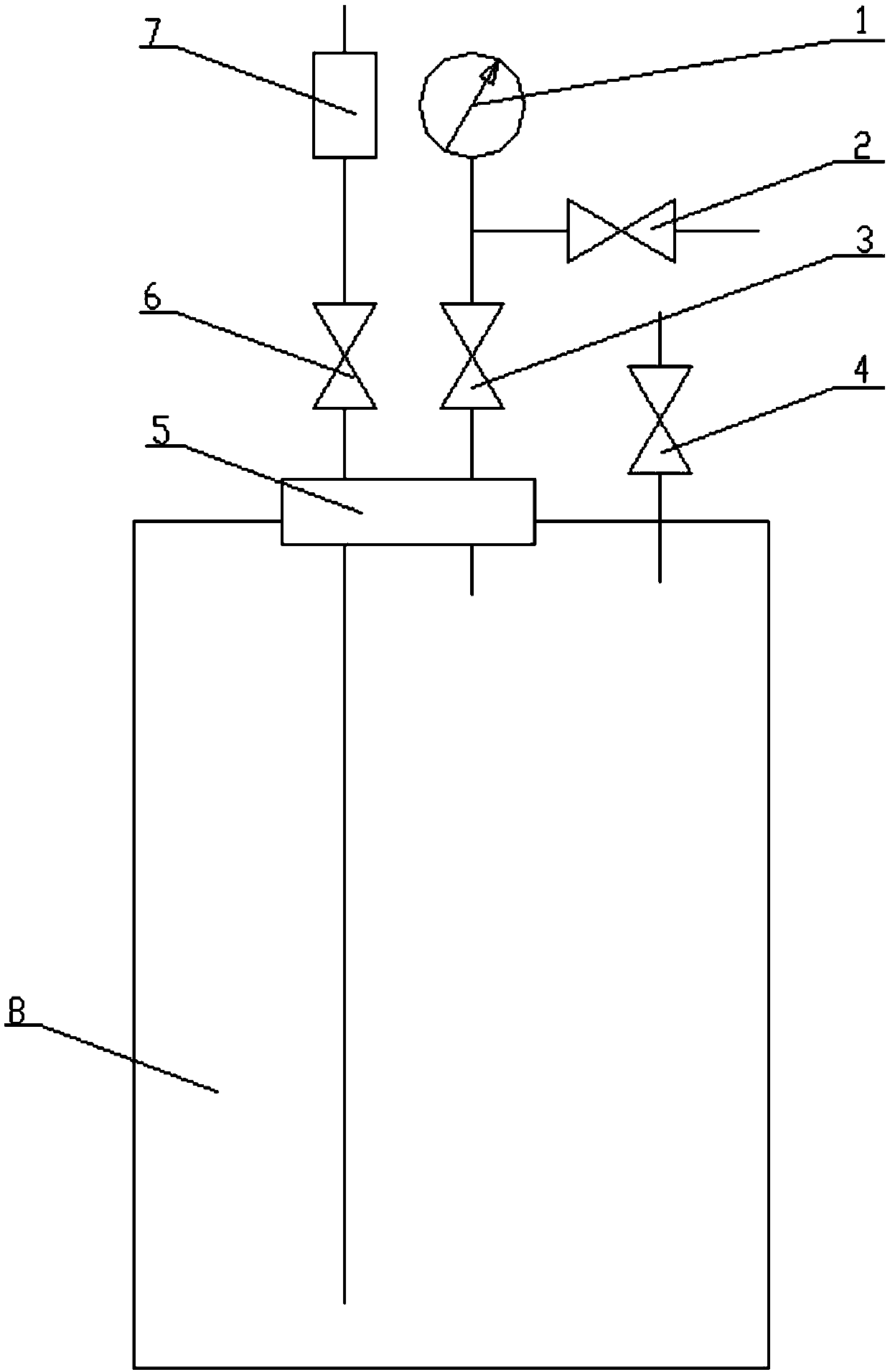

[0020] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] Such as figure 1 As shown, the water-cooled frequency converter ultra-pure coolant filling storage and filling device of the present invention includes a pressure gauge 1, a first two-way air valve 2, a second two-way air valve 3, a safety pressure relief valve 4, and a sanitary clamp-type barrel Cover 5, two-way liquid valve 6, liquid flowmeter 7, pressure container liquid tank 8; among them, the sanitary clamp type barrel cover 5 is installed on the upper part of the pressure container liquid tank 8, and the liquid pipe and gas pipe pass through the sanitary clamp type The bung 5 extends into the liquid tank 8 of the pressure container, the gas line pipe is connected to the second two-way air valve 3 and is arranged on the top of the liquid tank 8 of the pressure container, and the liquid line pipe is connected to the two-way liquid v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com