A ton-packaging umbrella-type filling head and a ton-packing method for the umbrella-type filling head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with embodiment the present invention is described in further detail:

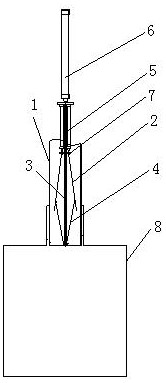

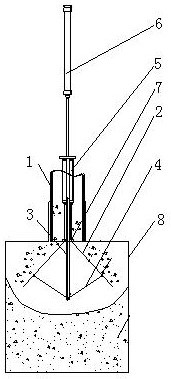

[0023] A ton packaging umbrella type filling head, such as figure 1 , 2 As shown, it includes a feeding pipe 1 connected to the silo. An umbrella retractable device is arranged in the feeding pipe 1. The umbrella retractable device can move up and down in the feeding pipe and can extend to the bottom of the feeding pipe 1. The umbrella cover retractable device comprises a tapered umbrella cover 2, and the umbrella cover retractable device makes the umbrella cover form different feeding angles, and the feeding angle varies with the degree of opening of the umbrella cover 2. After falling material falls on the umbrella surface 2, it enters the ton packing bag below. The invention evenly distributes the falling materials in the packaging bag, and the density distribution is more uniform during the filling process, avoiding the problem of insufficient filling of the packaging bag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com