Full-automatic door leaf glass glue turning equipment

A fully automatic, door-leaf technology, which is applied in the direction of pre-treatment surface, device for coating liquid on the surface, coating, etc., can solve the problems of inability to seal fundamentally, low gluing efficiency, and reduced efficiency, so as to avoid The effect of uneven glue application, saving glue drying time, and saving glue application time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

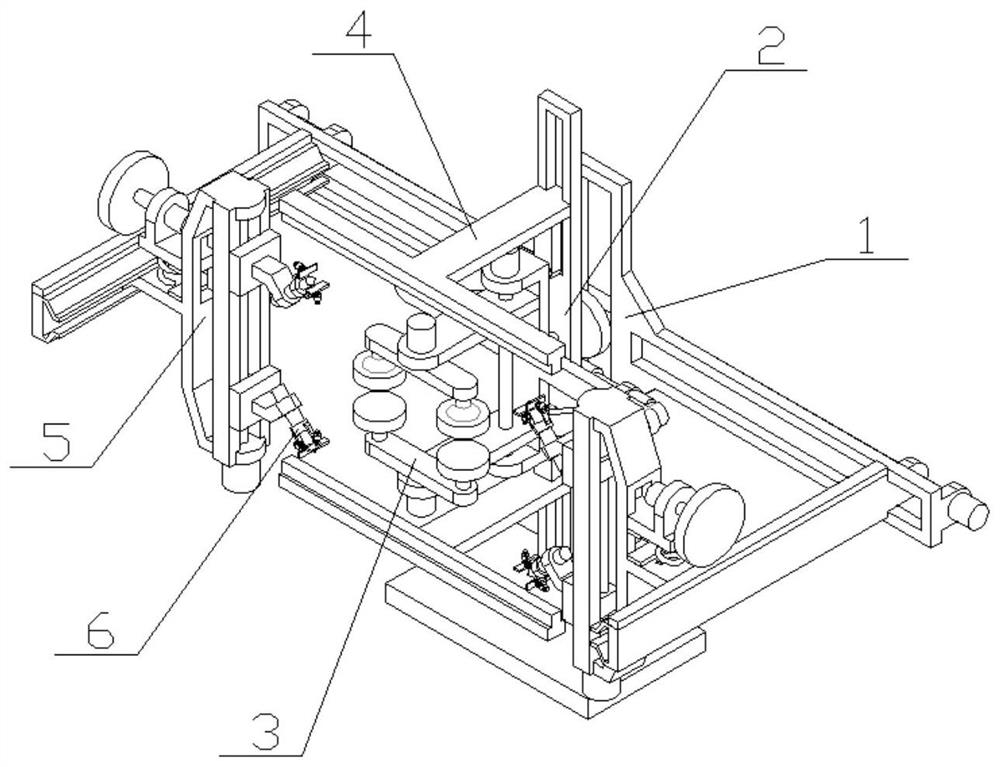

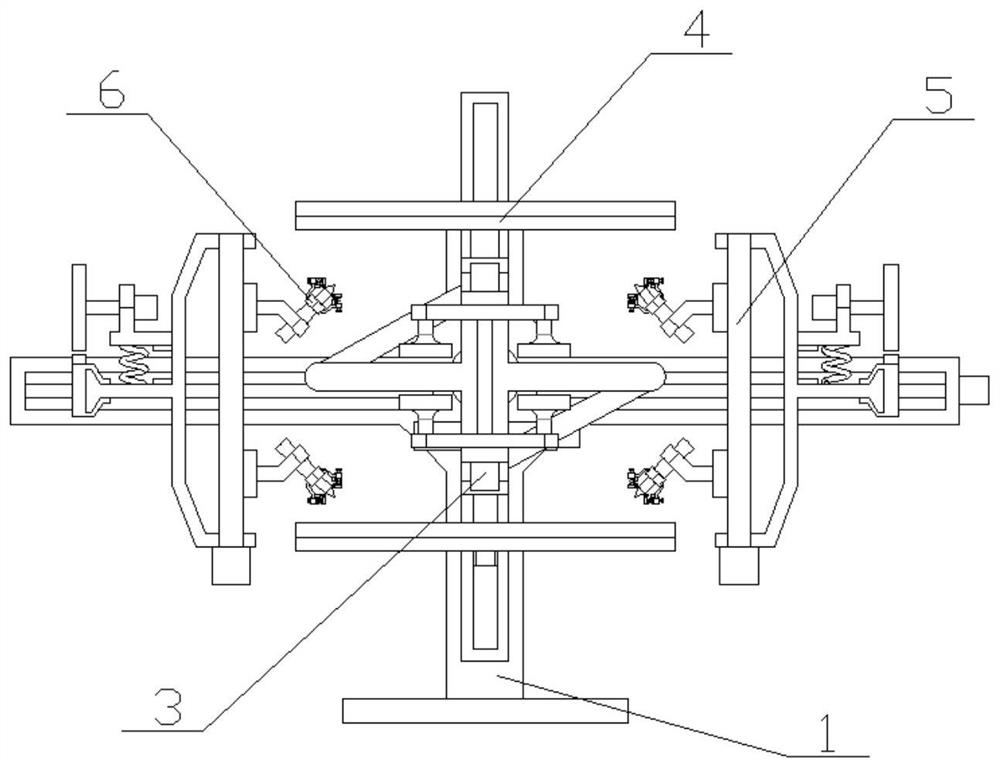

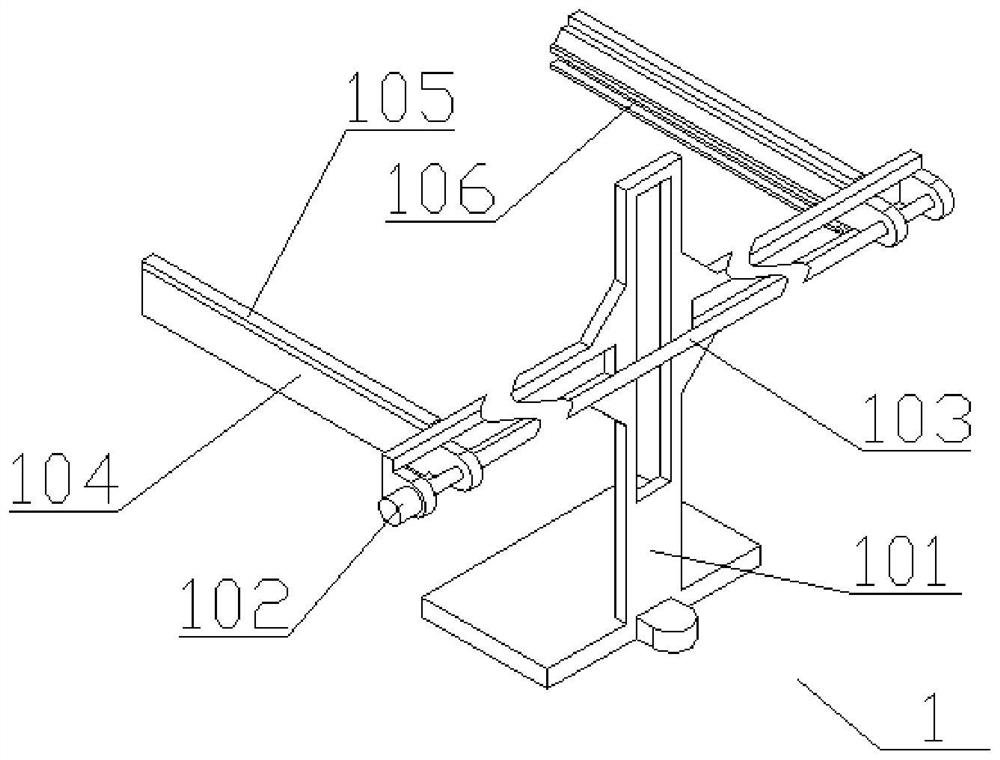

[0029] Combine below figure 1 -7 illustrates the specific implementation of the present invention, a fully automatic door glass turning device, including a supporting mechanism 1, a moving mechanism 2, a fixing mechanism 3, a heating mechanism 4 and a sealing mechanism 5, and the moving mechanism 2 is slidably connected to the On the supporting mechanism 1, the fixing mechanism 3 is connected to the middle of the moving mechanism 2, the two heating mechanisms 4 are respectively arranged on the upper and lower sides of the moving mechanism 2, and the two sealing mechanisms 5 They are respectively arranged on both sides of the support mechanism 1; compared with the traditional device, when the glass is in a vertical state during the flipping process, it can be combined with the glass rotation to perform simultaneous sealing on both sides of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com