A corrugating machine upper rubber roller glue discharge control device

A control device and corrugating machine technology, applied in the field of corrugating machines, can solve the problems of high processing cost, high processing difficulty, low precision, etc., and achieve the effect of uniform glue output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

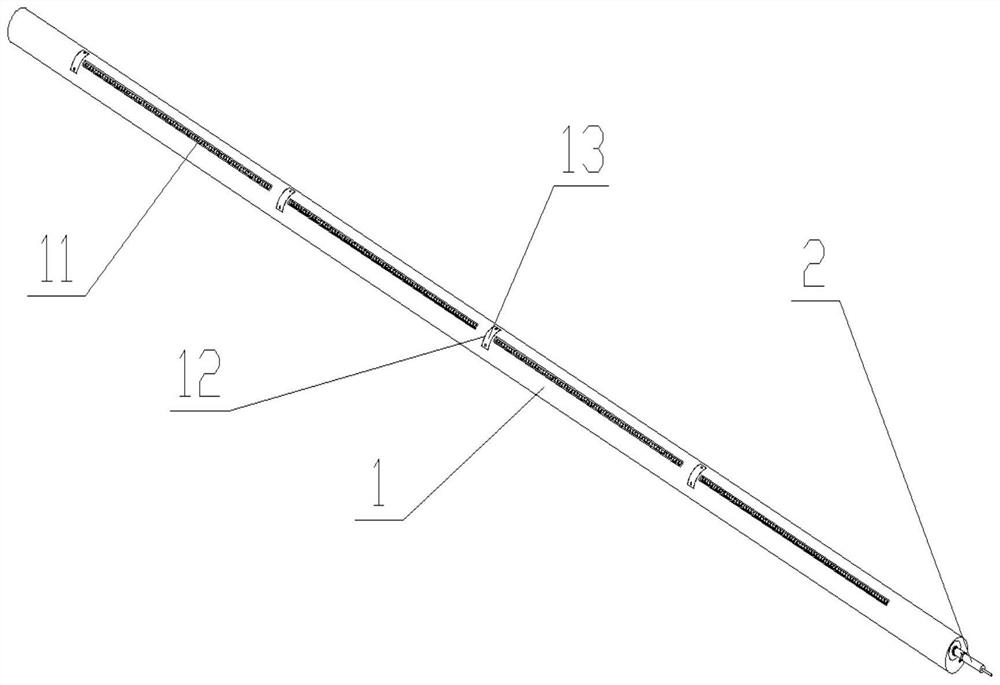

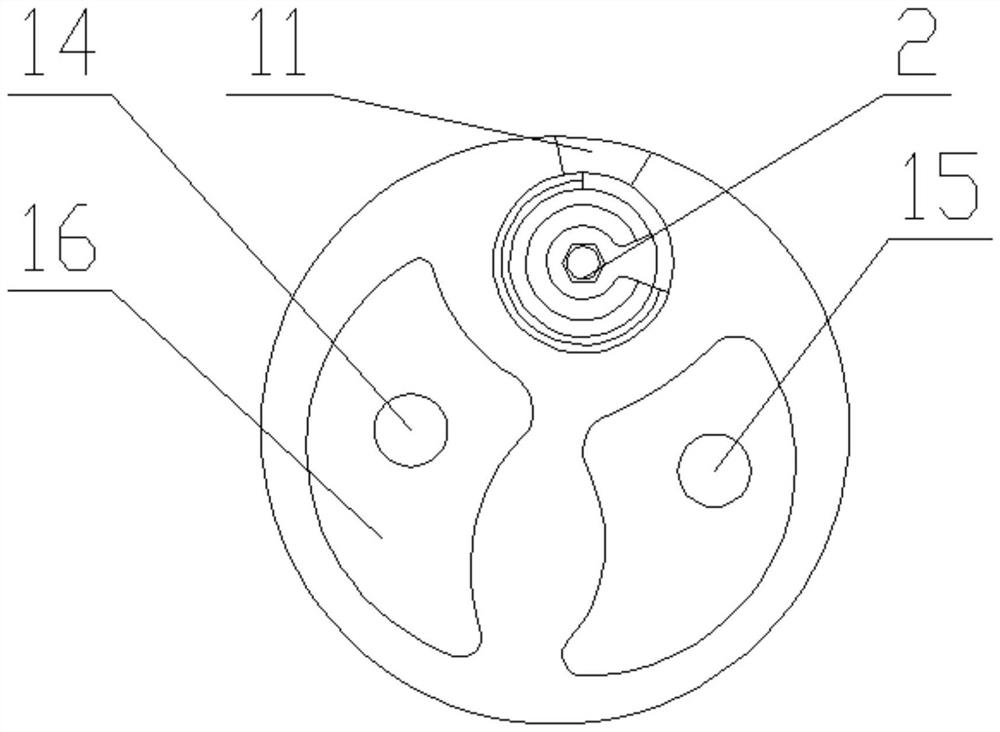

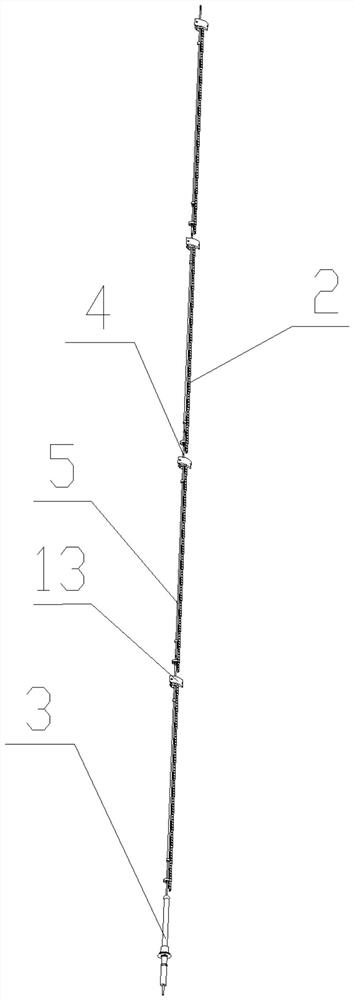

[0029] like Figure 1 to Figure 8 Shown; a corrugating machine upper rubber roller glue control device, including a hot glue delivery column 1 and a pressure control mechanism 2, the hot glue delivery column 1 is provided with a U-shaped heating channel 16 and a glue guide channel, the control The working end of the pressing mechanism 2 is set in the glue guide channel, and the hot glue conveying column 1 is provided with at least two glue outlet grooves 11, the glue outlet grooves 11 are connected with the glue guide channel, and one side of the glue outlet grooves 11 is set There is a positioning groove 12, the supporting positioning block 13 adjusted by the auxiliary pressure control mechanism 2 is arranged in the positioning groove 12, an air outlet 14 and an air inlet 15 are arranged at one end of the hot glue conveying column 1, and the air outlet 14 and the air inlet The air inlet holes 15 are respectively connected to the two ends of the U-shaped heating channel 16, an...

Embodiment 2

[0033] On the basis of Embodiment 1, the mechanical seal 34 is provided with a dial 35, the dial 35 is provided with a positioning pointer 36 for positioning the rotation angle of the pressure regulating mechanism 5, and the external rotation column 31 is sleeved with a matching positioning pin. The dynamic positioning pointer 37 of the pointer 36; the one side of the outer rotation column 31 is provided with a scale plate; side, the positioning block 59 is conical; the adjusting block 58, the positioning block 59 and the adjusting hole 510 are all polygonal; the polygon is hexagonal; the adjusting ball 41 is set near the side of the threaded locking rod 33 There is a plane on which bite patterns are arranged; the length of the pressure regulating rubber groove 52 increases sequentially from the adjustment device 3 to the direction of the supporting positioning block 13 .

[0034] It is determined by setting the dial 35 that the rotation state of the adjustment block 58 can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com