Preparation method of PVDF (Polyvinylidene Fluoride) glue solution

A technology of glue and liquid surface, which is applied in the direction of structural parts, electrical components, battery electrodes, etc., can solve the problems of unfavorable dissolution, easy formation of micelles, low solid content and low viscosity, so as to accelerate dissolution, reduce glue making time, Improve glue efficiency and glue uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

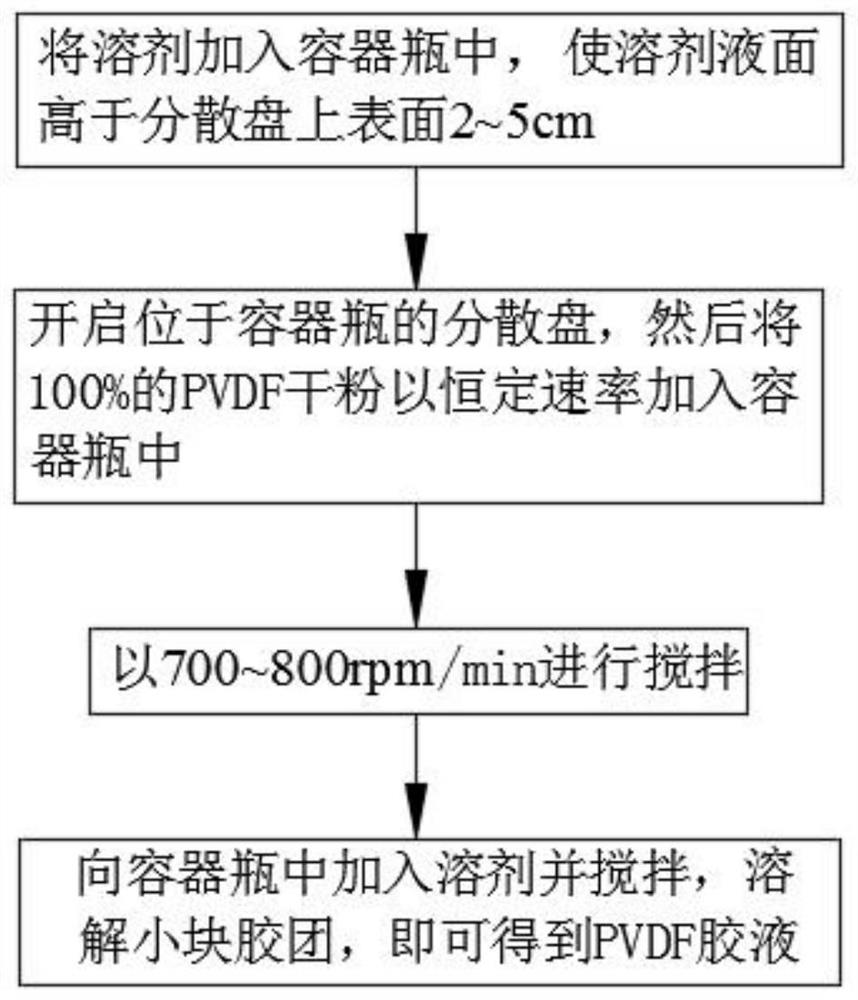

[0032] The preparation method of a kind of PVDF glue solution that this embodiment 1 provides, comprises the following steps:

[0033] S1: According to the volume of the container and the total weight of the glue to be prepared, add 70% of the N-methyl pyrrolidone solvent required for the glue to the container bottle, so that the liquid level of the N-methyl pyrrolidone solvent is higher than The upper surface of the dispersion plate is 2cm;

[0034] S2: open the dispersion disc located in the container bottle, so that the stirring rate of the dispersion disc is 700rpm / min, and the PVDF dry powder is added to the container bottle at a rate of 2.5kg / min;

[0035] S3: stirring at 700rpm / min for 90min;

[0036] S4: Add the remaining 30% N methyl pyrrolidone solvent into the container bottle and stir for 300 min, the stirring speed is 750 rpm / min, dissolve the small pieces of micelles, and then 1500 L of PVDF glue solution can be obtained.

[0037] The PVDF glue that the present...

Embodiment 2

[0047] The preparation method of a kind of PVDF glue solution that this embodiment 2 provides, comprises the following steps:

[0048] S1: According to the volume of the container and the total weight of the glue to be prepared, add 75% of the N-methyl pyrrolidone solvent required for the glue to the container bottle, so that the liquid level of the N-methyl pyrrolidone solvent is higher than The upper surface of the dispersion plate is 2cm;

[0049] S2: open the dispersion disc located in the container bottle, so that the stirring rate of the dispersion disc is 700rpm / min, and the PVDF dry powder is added to the container bottle at a rate of 2.5kg / min;

[0050] S3: stirring at 700rpm / min for 90min;

[0051] S4: Add the remaining 25% N methyl pyrrolidone solvent to the container bottle and stir for 300 min, the stirring speed is 750 rpm / min, dissolve the small pieces of micelles, and then 1500 L of PVDF glue solution can be obtained.

[0052] The PVDF glue that the present e...

Embodiment 3

[0062] The preparation method of a kind of PVDF glue solution that this embodiment 3 provides, comprises the following steps:

[0063] S1: According to the volume of the container and the total weight of the glue to be prepared, add 75% of the N-methyl pyrrolidone solvent required for the glue to the container bottle, so that the liquid level of the N-methyl pyrrolidone solvent is higher than The upper surface of the dispersion plate is 3cm;

[0064] S2: open the dispersion disc located in the container bottle, so that the stirring rate of the dispersion disc is 750rpm / min, and the PVDF dry powder is added to the container bottle at a rate of 2.5kg / min;

[0065] S3: stirring at 750rpm / min for 90min;

[0066] S4: Add the remaining 25% N methyl pyrrolidone solvent to the container bottle and stir for 300 min, the stirring speed is 750 rpm / min, dissolve the small micelles, and then 1500 L of PVDF glue can be obtained, and the solid content is 6.8% .

[0067] The PVDF glue that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com