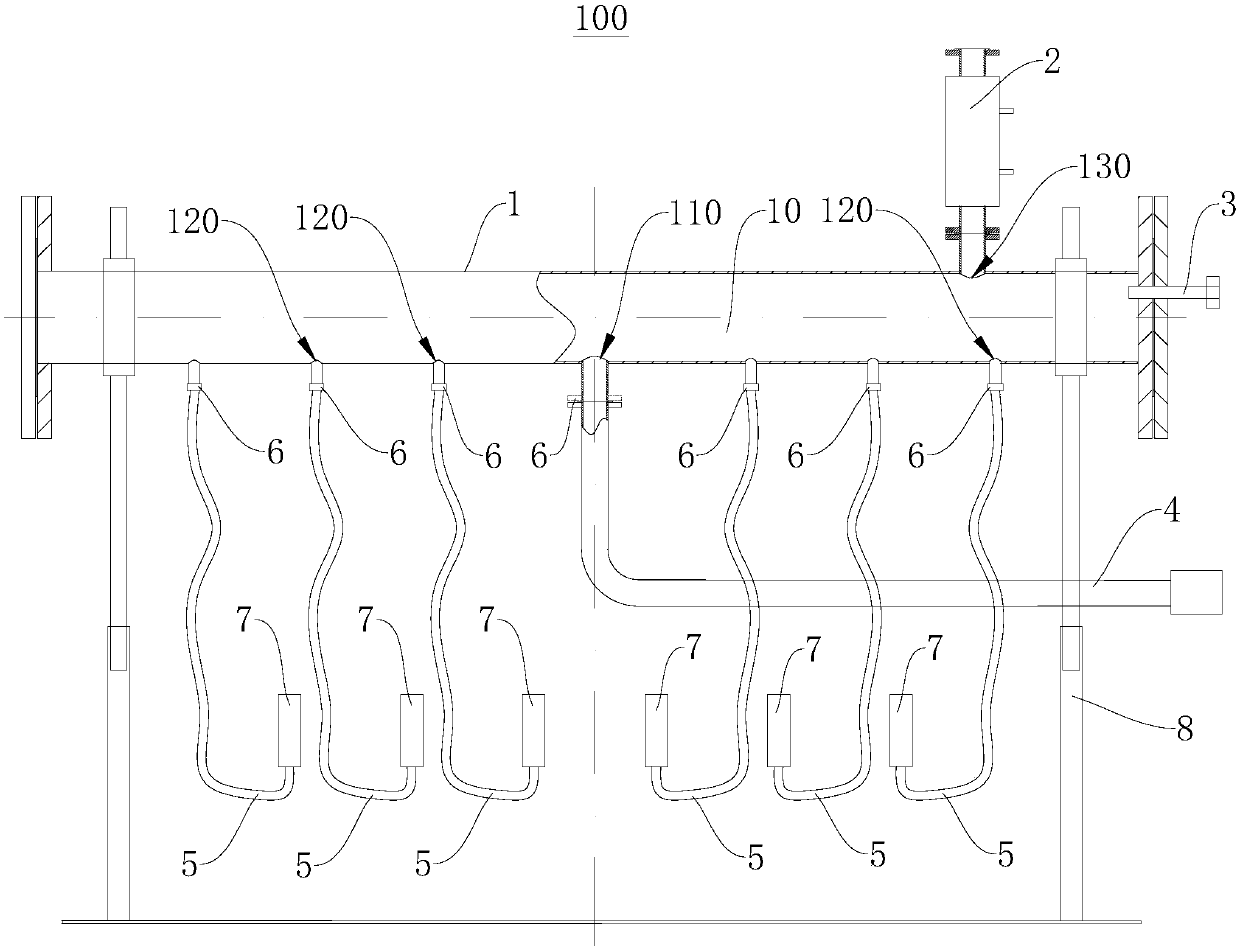

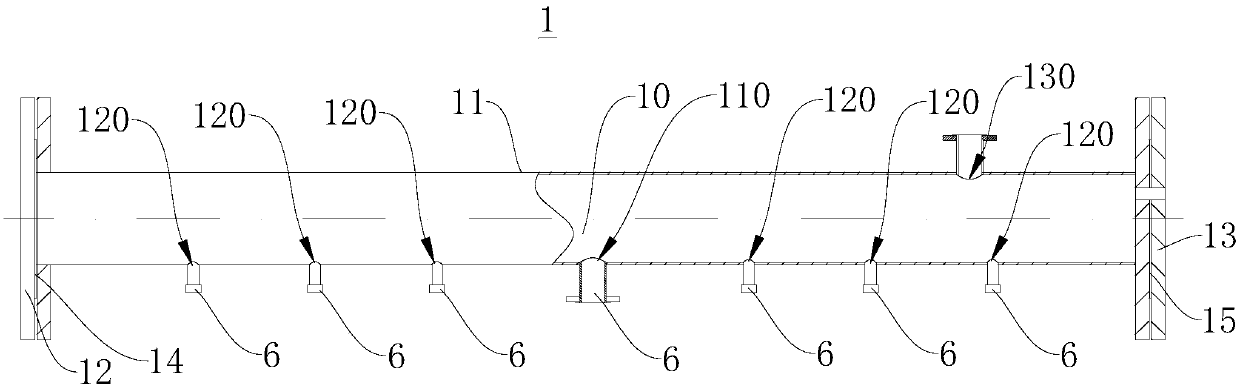

Liquid filling system and liquid medicine filling machine provided with same

A filling system and liquid technology, applied in liquid bottling, liquid processing, packaging, etc., can solve the problems of high unqualified rate of filling products, inability to recycle, waste, etc., to avoid insufficient filling volume and improve filling. The effect of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

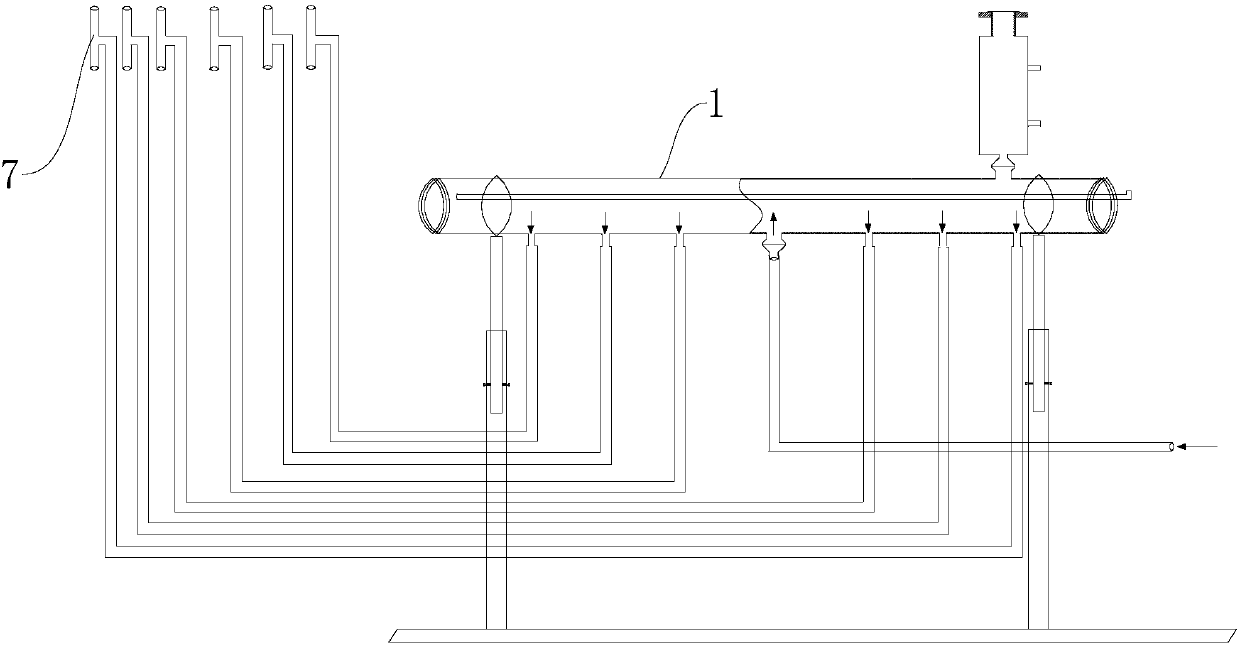

[0057] Such as image 3 As shown, the components of the buffer tank 1 are assembled, and the installed air filter adopts a polytetrafluoroethylene membrane filter, and then the buffer tank 1 is fixed on the filling machine. At this time, the height of the tank body 11 is below the filling pump 7. After everything is ready, turn on the filling machine and start filling. The final statistical results found that there were 6 times of serious shortage of filling volume in the whole filling process, and the number of rejected bottles due to serious shortage of filling volume was 72 bottles in total, with an average of 12 bottles each time. Finally, all the liquid medicine was poured out and weighed The total weight is 1.88Kg. After the filling, the buffer tank 1 is disassembled and the filling residue is poured out to weigh a total of 0.96Kg. The total of the two is 2.84Kg, which is equivalent to a direct loss of 53 bottles.

example 2

[0059] Such as Figure 4 As shown, the components of the buffer tank 1 are assembled, and the air filter installed is a polytetrafluoroethylene membrane filter, and then the buffer tank 1 is fixed on the filling machine. At this time, the height of the tank body 11 is flush with the filling pump 7 , when everything is ready, turn on the filling machine and start filling. The final statistical results found that there were 6 times of serious shortage of filling volume in the whole filling process. The number of bottles rejected due to serious shortage of filling volume was 74 bottles, with an average of 12.3 bottles each time. Finally, all the liquid medicine was poured out and weighed. The total weight is 1.93Kg. After the filling, the buffer tank 1 is disassembled and the filling residue is poured out to weigh a total of 0.41Kg. The total of the two is 2.34Kg, which is equivalent to a direct loss of 43 bottles.

example 3

[0061] Such as Figure 5 As shown, the components of the buffer tank 1 are assembled, the air filter installed is a polytetrafluoroethylene membrane filter, and then the buffer tank 1 is fixed on the filling machine. At this time, the height of the tank body 11 is above the filling pump 7 , when everything is ready, turn on the filling machine and start filling. After the final statistical results, it was found that there were 6 times of serious shortage of filling volume in the whole filling process. The number of bottles rejected due to serious shortage of filling volume was 70 bottles, with an average of 11.7 bottles each time. Finally, all the liquid medicine was poured out. The total weight is 1.76Kg. After filling, the buffer tank 1 is disassembled and the filling residue is poured out and the total weight is 0.02Kg. The total of the two is 1.78Kg, which is equivalent to a direct loss of 33 bottles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com