Hollow blade

A hollow blade and vane technology, which is applied to the components of pumping devices for elastic fluids, non-variable displacement pumps, machines/engines, etc., can solve the problems of difference in impact resistance and uneven rigidity of blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

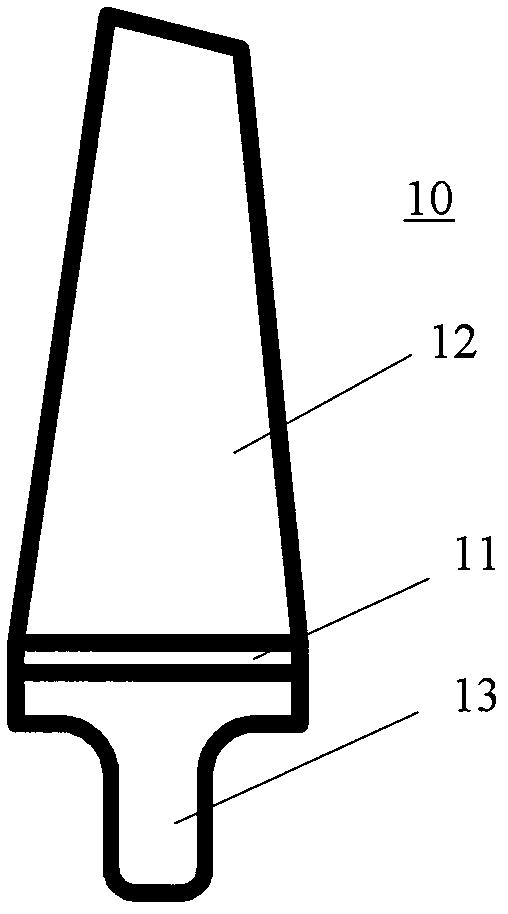

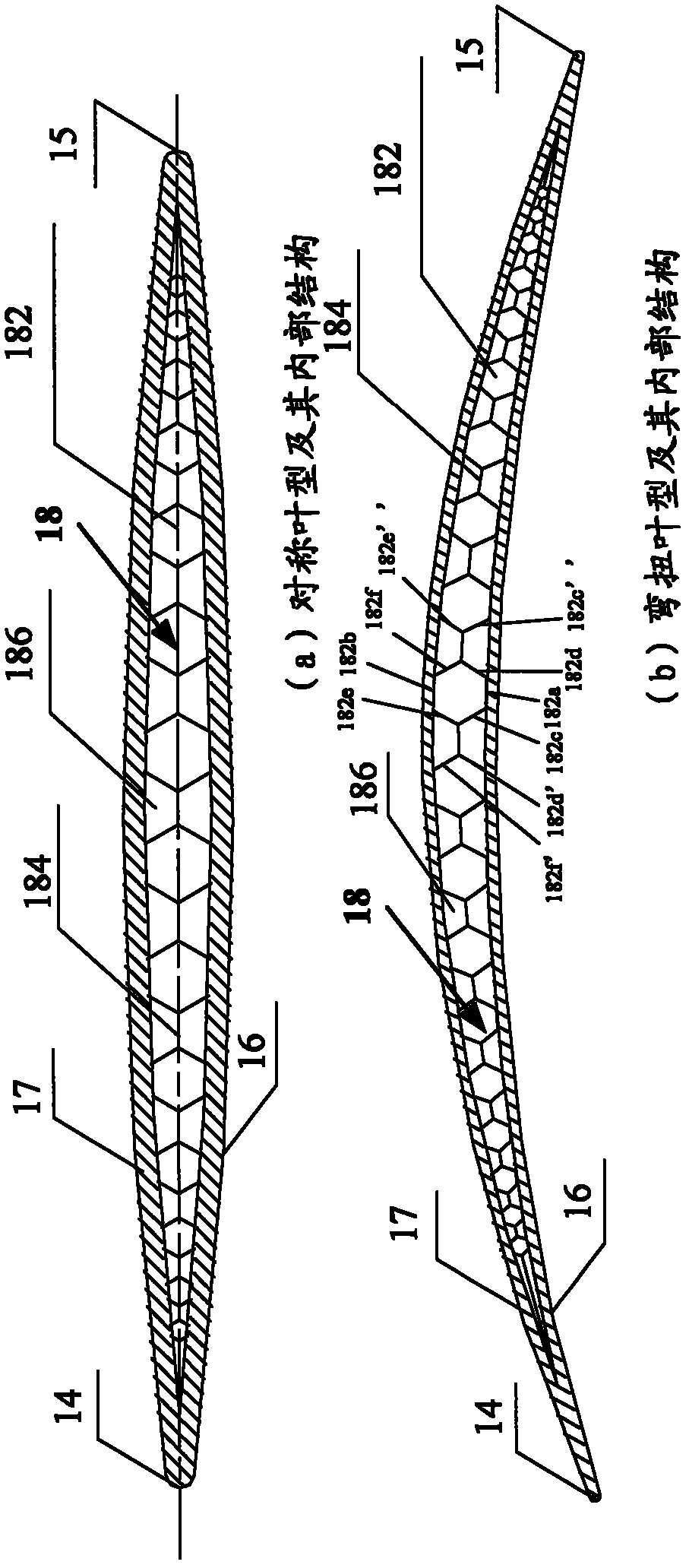

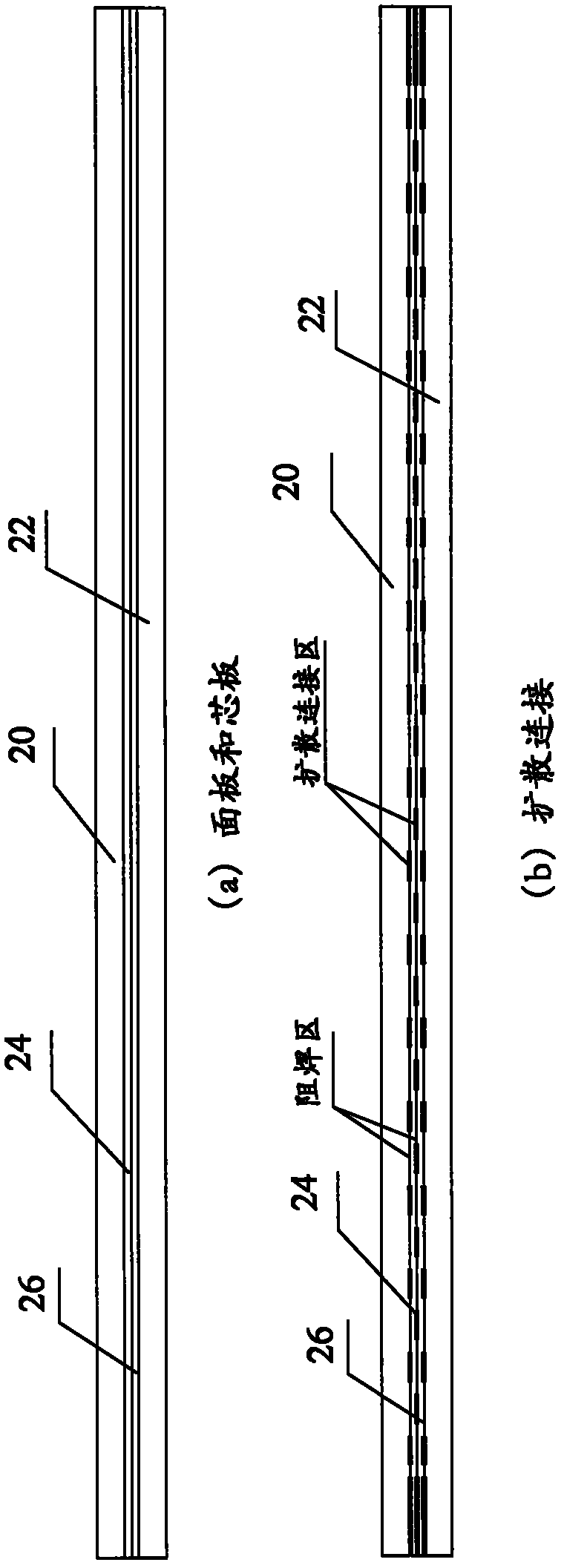

[0026] like Figure 1-Figure 2 As shown, among them, figure 2 (a) and (b) represent two different airfoil types, namely symmetrical airfoil type and curved and twisted airfoil type. The fan blade 10 includes a tenon 11 and an airfoil profile 12 . The tenon 11 has a wedge shape or other suitable shape for being installed in a correspondingly shaped tenon groove on the fan disc 13 . The airfoil profile 12 has a pressure side portion 16 and a suction side portion 17 extending from a leading edge 14 to a trailing edge 15, in combination with image 3 , The pressure surface part 16 and the suction surface part 17 are respectively formed by panels 20, 22, and the material of the panels 20, 22 is titanium alloy. Optionally, the panels 20, 22 can also be made of steel, such as stainless steel. In the cavity formed by the pressure surface portion 16 and the suction surface portion 17, there is also a vibration damping portion 18, which is arranged at intervals from the leading edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com