Fully-prefabricated concrete-filled steel tube frame structure and assembling method

A technology of concrete filled steel tube and frame structure, which is applied in building construction, construction, and building material processing, etc., can solve the problems of low construction efficiency, low pouring quality, affecting the bearing capacity of components, etc., and achieves short construction period and integrity. Good, improve the effect of overall connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

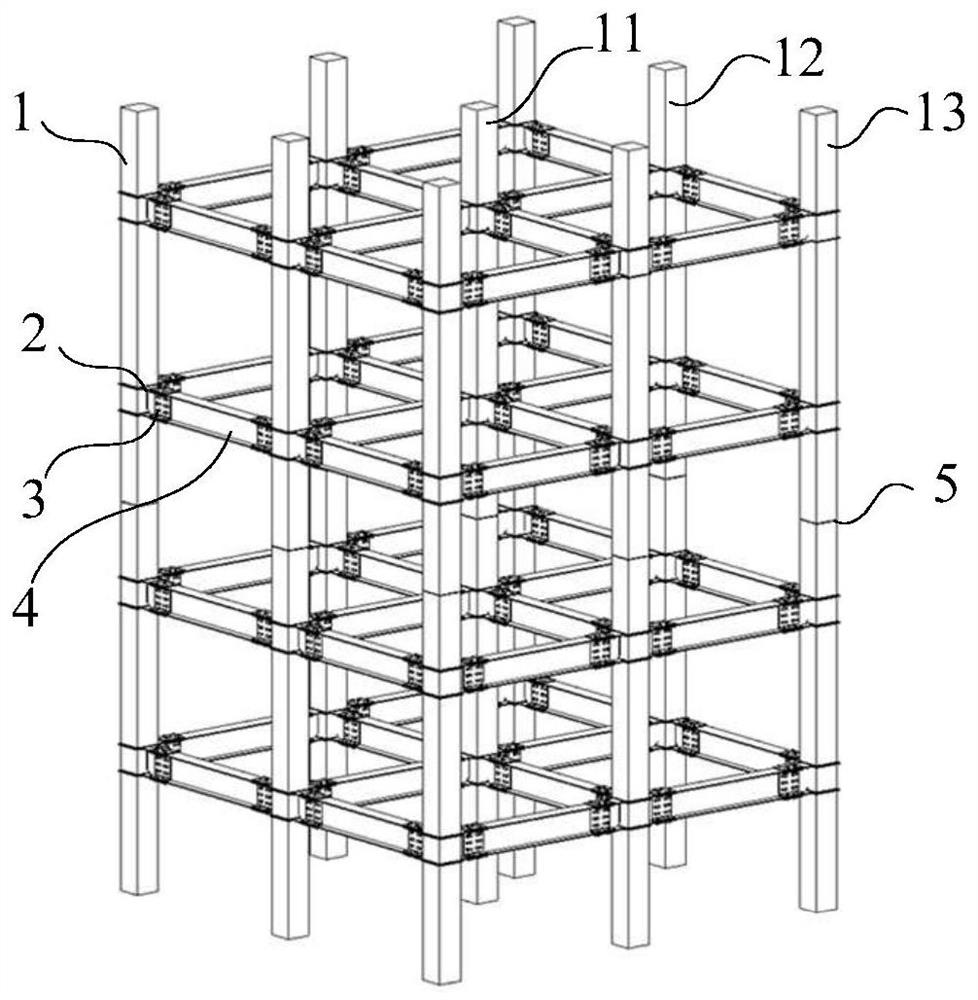

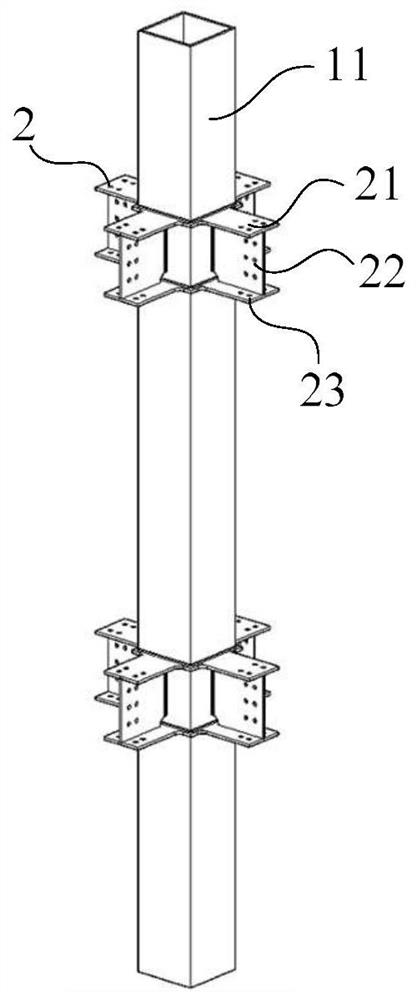

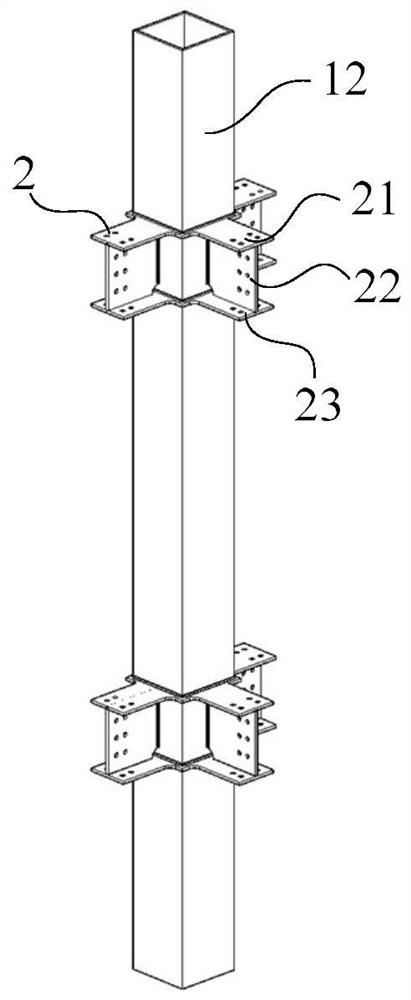

[0047] This embodiment provides a fully prefabricated steel tube concrete frame structure, such as figure 1As shown, several columns 1 and several beams 4 are included. The column 1 is preferably a square steel pipe structure. Of course, the column 1 can also be a column, a rectangular column, etc., and its shape is not limited. Concrete is poured inside the square steel pipe. The column 1 is provided with a prefabricated node 2, the node 2 and the beam 4 are connected horizontally through the first connecting piece 3, and the two columns 1 in the same vertical direction are vertically connected through the second connecting piece 5, and the column 1 is connected vertically with the second connecting piece 5. It is divided into central column 11, side column 12 and corner column 13, which are connected with each other by cross beam 4 to form an integral square steel tube concrete frame structure. Among them, the central column 11 is located inside the frame structure, the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com