Machining method of micro deep hole of steel with carbon content of less than or equal to 0.6%

A processing method and carbon content technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of long processing cycle, difficult technical precision to meet precision parts, low yield rate, etc., to achieve processing yield And the effect of high processing accuracy, excellent clamping accuracy and dynamic balance, and processing cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

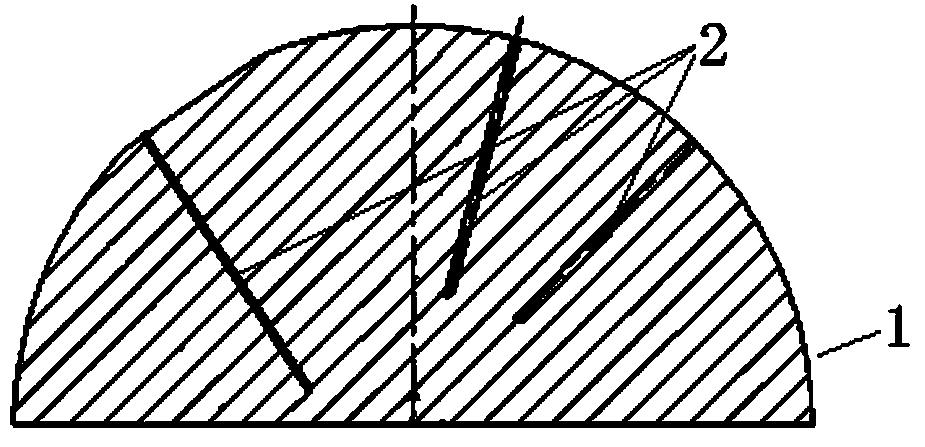

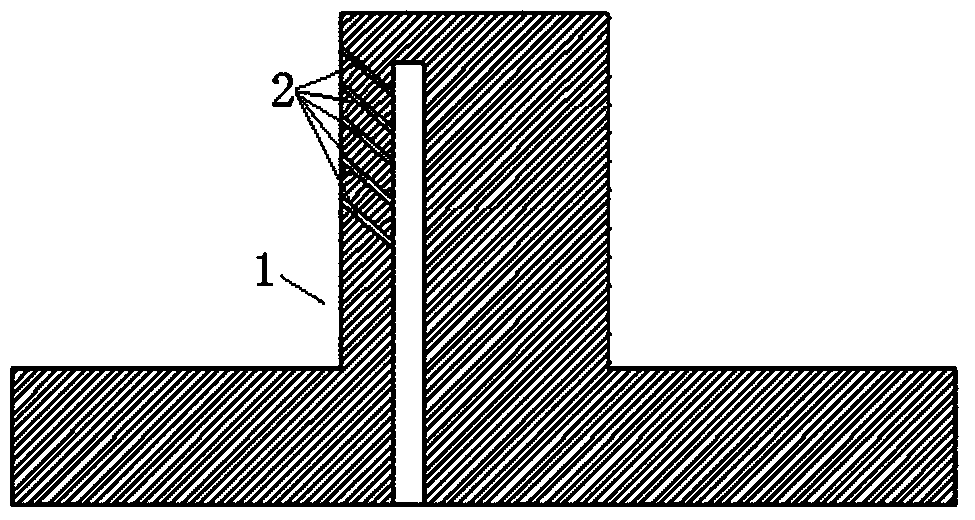

[0044] The present invention uses a part made of stainless steel (such as 304 stainless steel) with a carbon content of ≤0.6% as the workpiece to be processed. The hole designed on the workpiece is a normal micro deep hole structure. The diameter of the hole is about The hole depth is 0.3mm, the hole depth is about 5mm, and the ratio of hole depth to hole diameter is about 17, which belongs to a typical deep hole structure. The workpiece and the hole pattern designed on the workpiece can be found in figure 1 As shown, it needs to be specially explained that the workpiece and the hole pattern on the workpiece that the present invention can adapt to are not limited to figure 1 example in .

[0045] Processing process of the present invention is to take following main process measure and realize:

[0046]Measure 1. Use the five-axis linkage high-speed machining center with high performance, high-speed action, and light-load cutting as the processing equipment, and use the space...

Embodiment 2

[0066] The present invention uses a part made of medium carbon steel with a carbon content of ≤0.6% as the workpiece to be processed, and the hole designed on the workpiece is a normal micro deep hole structure, and the diameter of the hole is about 0.25mm , The hole depth is about 2mm, and the ratio of hole depth to hole diameter is about 8, which belongs to a typical deep hole structure.

[0067] Processing process of the present invention is to take following main process measure and realize:

[0068] Measure 1. Use the five-axis linkage high-speed machining center with high performance, high-speed action, and light-load cutting as the processing equipment, and use the space rotation positioning function of its worktable or spindle to achieve accurate positioning of the normal hole position without special fixtures ;

[0069] The five-axis linkage high-speed machining center should have the following working parameters:

[0070] - The main shaft can work stably at 15000~3...

Embodiment 3

[0088] The present invention uses parts made of low-carbon steel with a carbon content of ≤0.6% as the workpiece to be processed. The hole designed on the workpiece is a normal micro deep hole structure, and the diameter of the hole is about 0.3mm. , The hole depth is about 4.5mm, and the ratio of hole depth to hole diameter is about 15, which belongs to a typical deep hole structure.

[0089] Processing process of the present invention is to take following main process measure and realize:

[0090] Measure 1. Use the five-axis linkage high-speed machining center with high performance, high-speed action, and light-load cutting as the processing equipment, and use the space rotation positioning function of its worktable or spindle to achieve accurate positioning of the normal hole position without special fixtures ;

[0091] The five-axis linkage high-speed machining center should have the following working parameters:

[0092] - The main shaft can work stably at 15000~35000r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com