Pneumatic tire

A pneumatic tire, tire circumferential technology, applied to tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve insufficient problems, improve drainage, improve partial wear resistance and straight travel sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, embodiments according to the present invention will be described with reference to the drawings. In addition, the following description is merely an example in nature, and is not intended to limit the present invention, its application, or its use. In addition, the drawings are schematic diagrams, and ratios of dimensions and the like are different from actual ratios of dimensions.

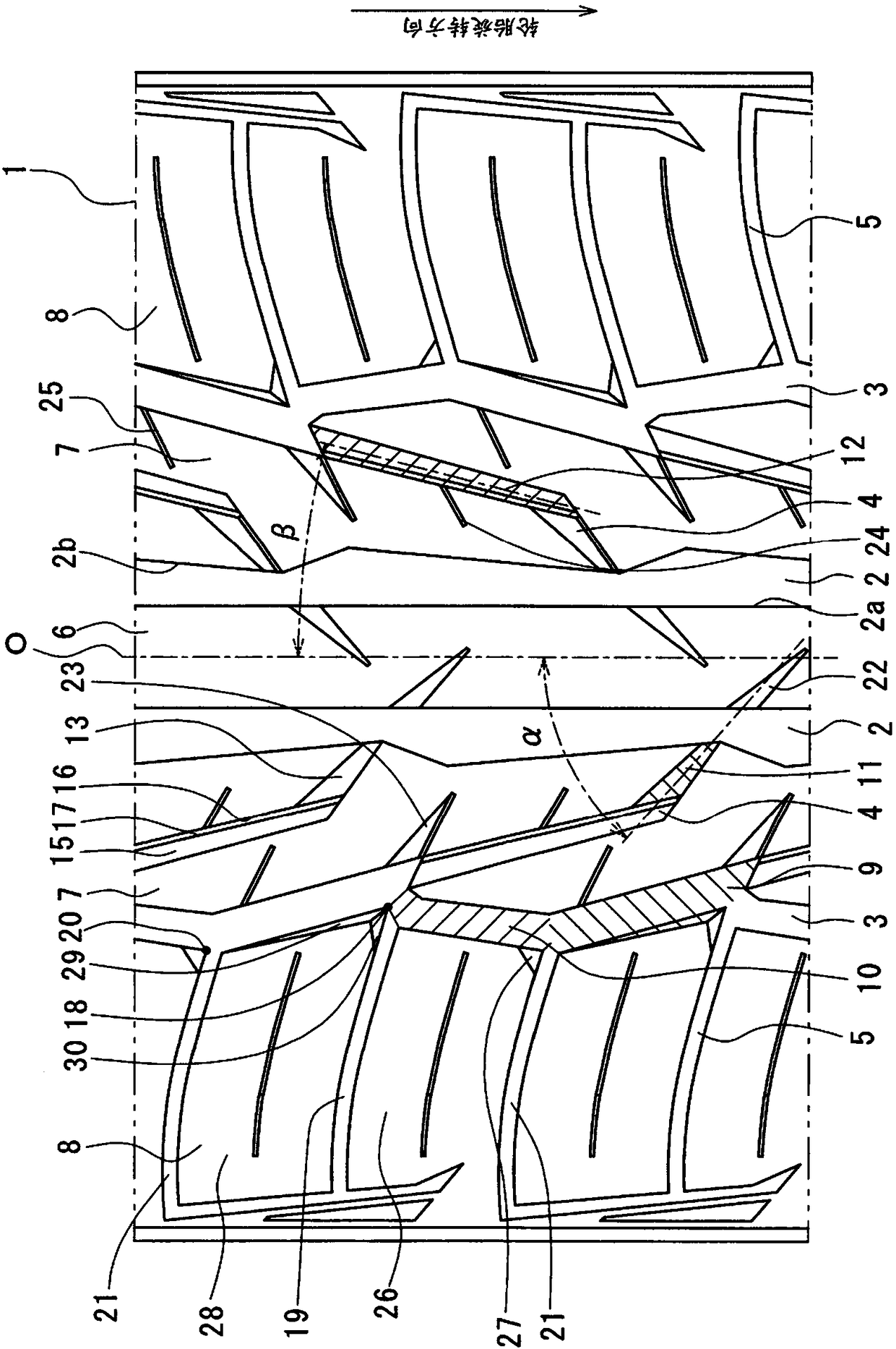

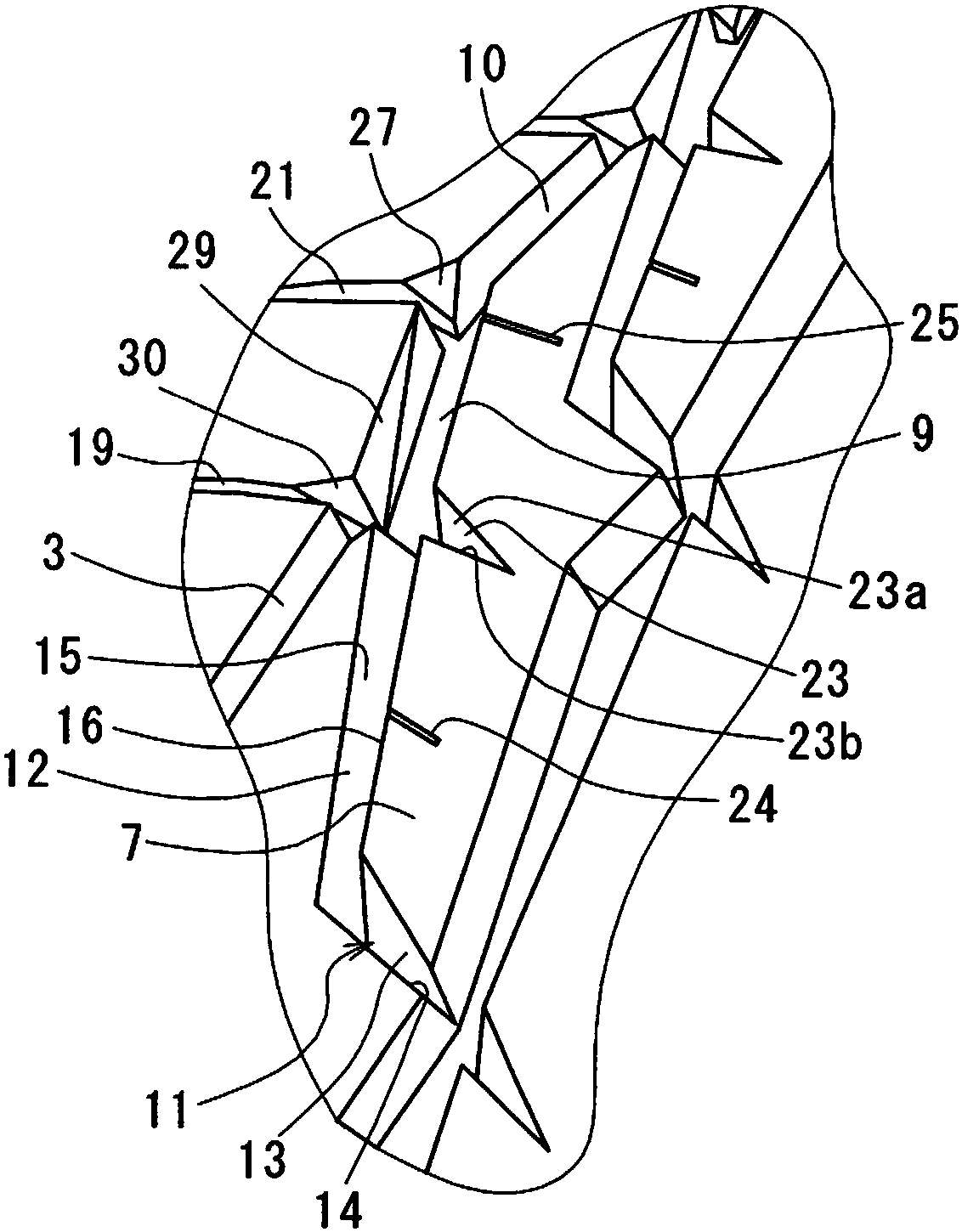

[0035] figure 1 It is a partially developed view of the tread surface 1 of the pneumatic tire according to the present embodiment, figure 2 is its partially enlarged perspective view. Through the center main groove 2, the shoulder main groove 3, the inclined groove 4, and the shoulder lateral groove 5, the land portion, that is, the center rib 6, the middle block 7, and the shoulder pattern are formed on the tread surface 1. Block 8. figure 1 The up and down direction is the tire circumferential direction, and the left and right direction is the tire width direction.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com