Winter tire which adopts tread pattern block of tunneling blade set

A tread pattern and pattern block technology, which is applied in the field of winter tires, can solve the problems of simple structure and unsatisfactory anti-skid effect, and achieve the effects of increased stability, strong grip and good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A preferred embodiment of the winter tire adopting the tread block of the tunneling blade set of the present invention will be described in detail below in conjunction with the accompanying drawings.

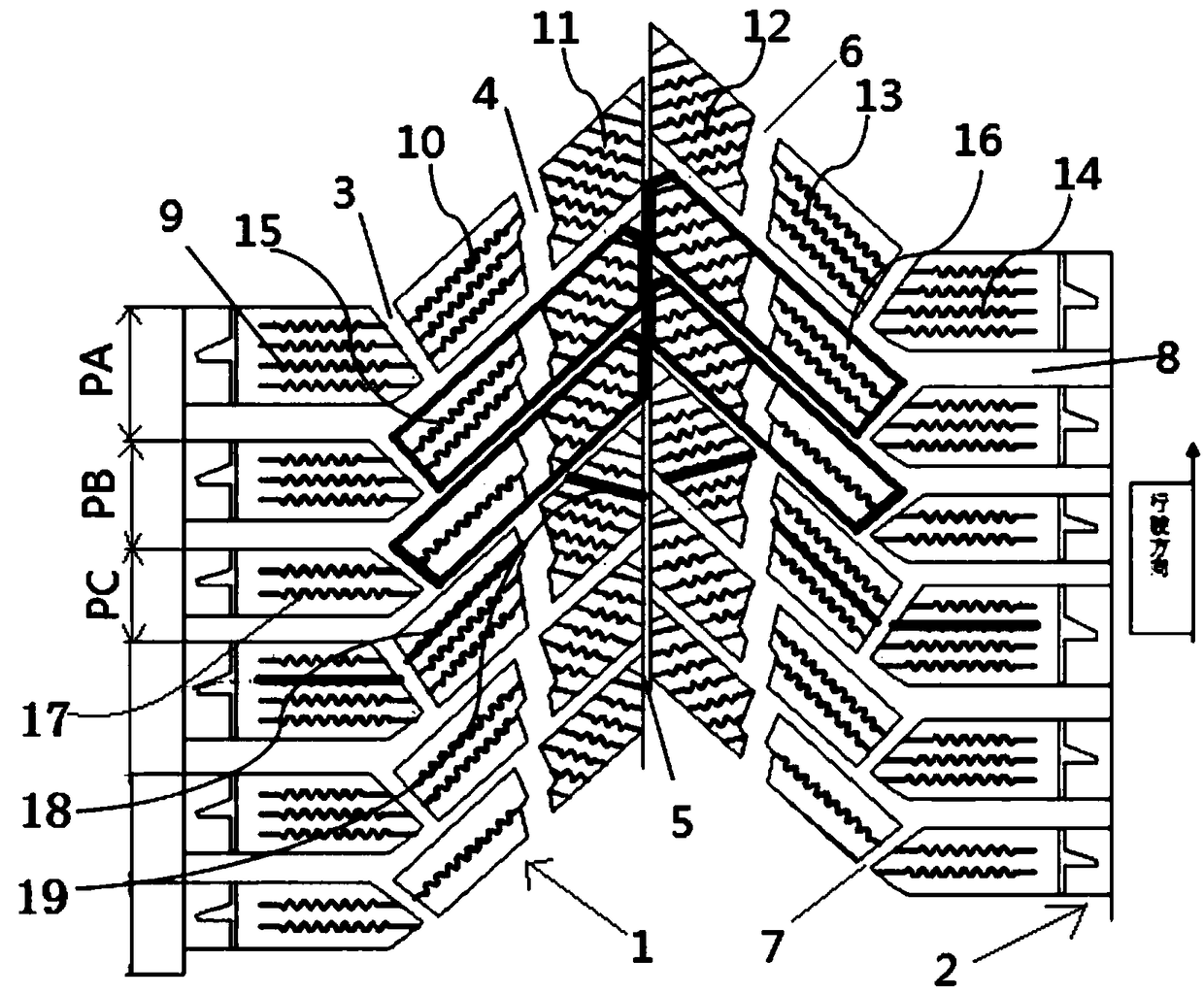

[0024] like figure 1 As shown, a winter tire adopting the tread block of the tunneling blade group, the block is limited by the groove, and the first pattern part composed of the first pattern block 9, the second pattern block 10, and the third pattern block 11 The second pattern part composed of the fourth pattern block 12, the fifth pattern block 13 and the sixth pattern block 14 is arranged alternately along the third circumferential main groove 5, and the distance between the first pattern part and the second pattern part is 3 block 11 Along half the width of the tread circumferential direction, the first pattern blade 15 is composed of the second pattern block 10 and the third pattern block 11, and the second pattern blade 16 is composed of the fourth pattern block 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com