Heat transfer sheet and radiator structure

A technology of heat transfer sheet and structure, which is applied in the direction of heat transfer modification, electric solid devices, semiconductor devices, etc., which can solve the problems of excessive cooling of the exothermic object and the inability of the exothermic object to fully exert its performance, so as to prevent excessive Effects of Cooling and Overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

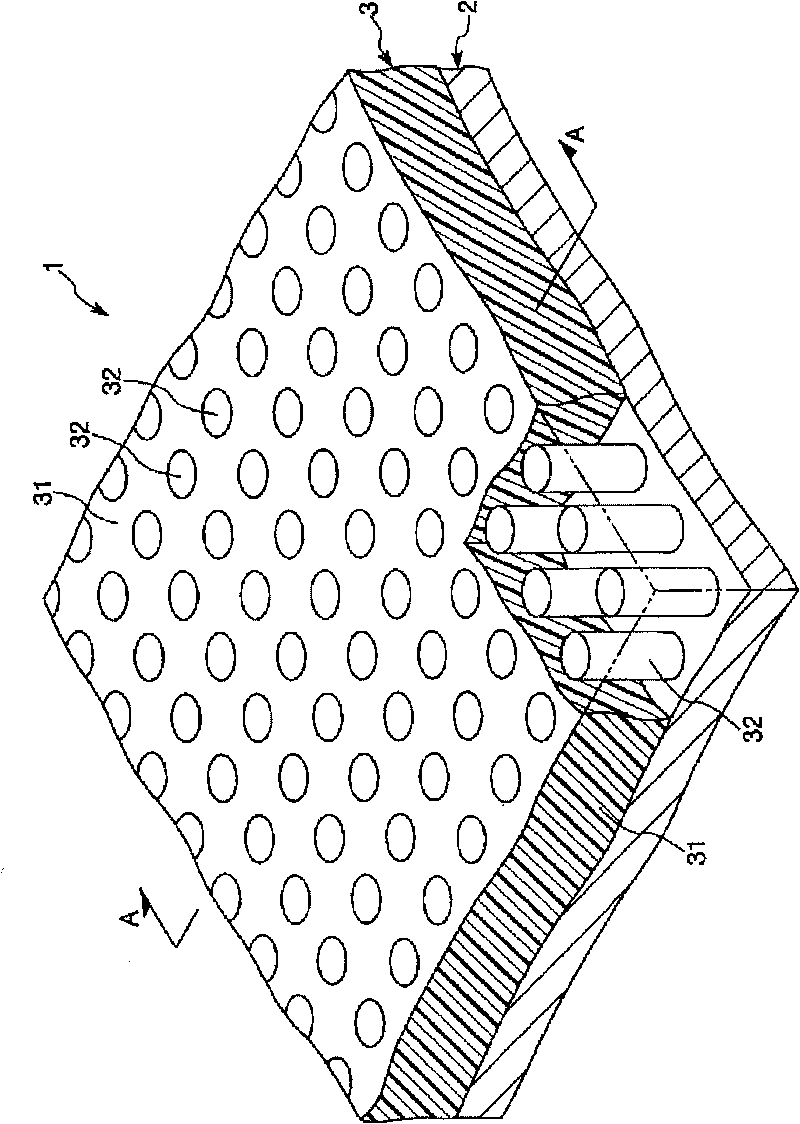

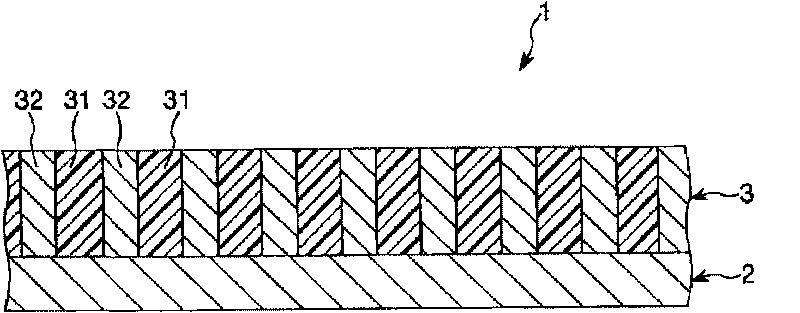

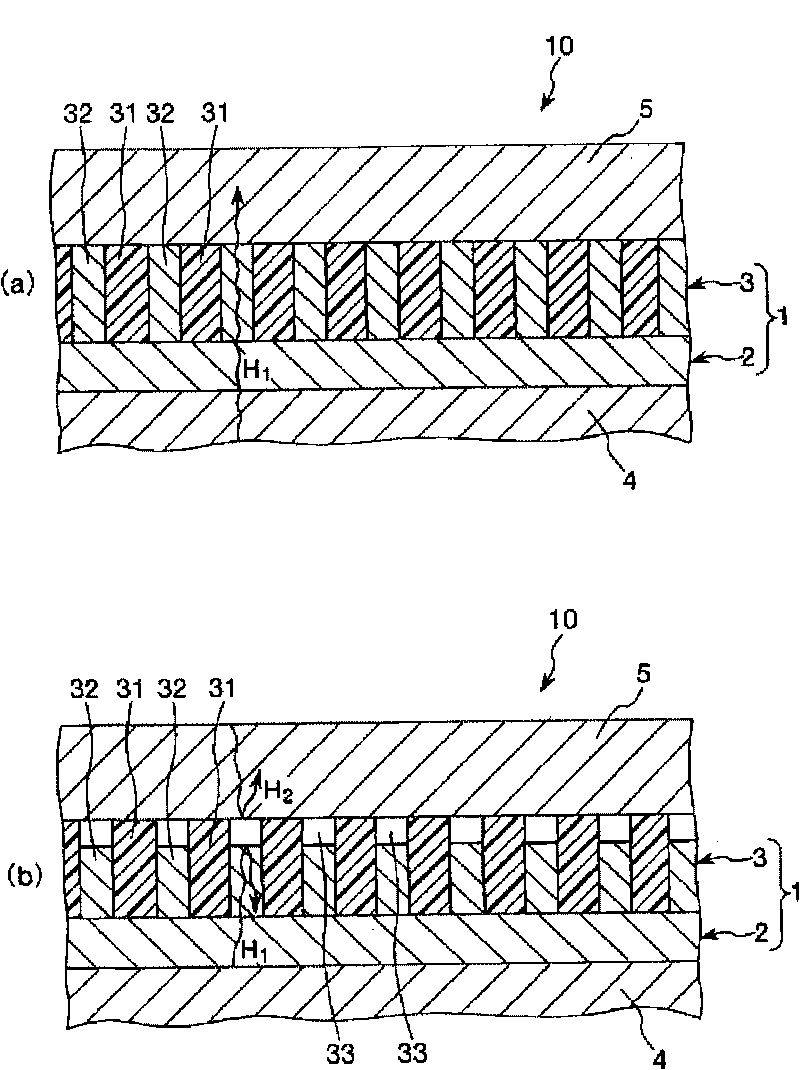

[0051] Below, based on Figure 1 to Figure 5 Embodiments of the heat transfer sheet of the present invention will be described in detail.

[0052] figure 1 is a perspective view showing a schematic structure of a preferred embodiment of the heat transfer sheet of the present invention, figure 2 yes figure 1 Middle A-A line sectional view, image 3 is for illustration figure 1 The diagram showing the action of the heat transfer fins, Figure 4 It is a figure for explaining the specific example of the exothermic structure of this invention, Figure 5 yes means Figure 4 A perspective view of the main part of the exothermic structure shown.

[0053] Such as figure 1 and figure 2 As shown, and as described later, the heat transfer sheet 1 of the present invention is used between a heat radiation target object and a counterpart object that must be radiated heat, and is used for performing the heat radiation target object and the counterpart body. Heat transfer fins for he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| weight-average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com