Polypropylene composite material and preparation method thereof

A composite material, polypropylene technology, applied in the field of plastics, can solve the problems of uneven dispersion of inorganic nano-fillers, and achieve the effect of being suitable for industrial production, preventing agglomeration, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] see figure 1 , figure 1 Show the flow chart of the preparation method of polypropylene composite material in the embodiment of the present invention, including the following steps:

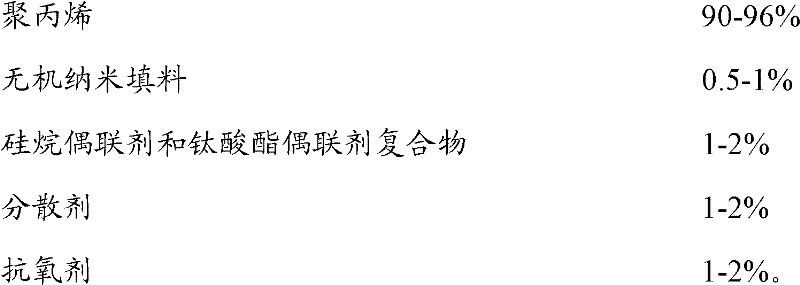

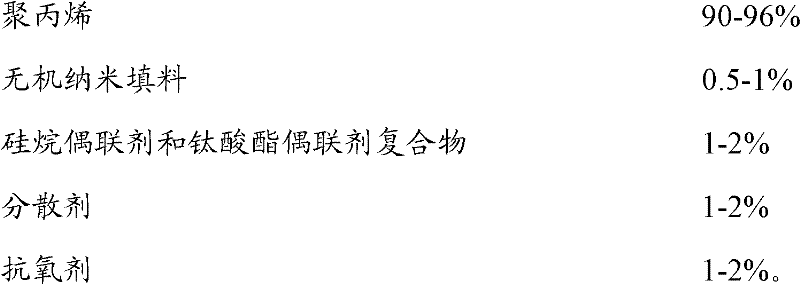

[0025] Step S01, mixing 0.5-1% by mass of inorganic nano-filler, and 1-2% by mass of silane coupling agent and titanate coupling agent compound, at a temperature of 70-120 Stirring at ℃ for 0.5-1 hour;

[0026] Step S02, adding 90-96% by mass of polypropylene, 1-2% by mass of dispersant and 1-2% by mass of antioxidant, at a temperature of 50-90°C Stirring under conditions for 0.5-1 hour to obtain a polypropylene composite material precursor;

[0027] Step S03, extruding the polypropylene composite material precursor to obtain a polypropylene composite material.

[0028] Specifically, the polypropylene, inorganic nanofiller, silane coupling agent and titanate coupling agent compound, dispersant and antioxidant are the same as those described above, and will not be repeated here.

[0029...

Embodiment 1

[0036] The nanometer calcium carbonate that is 0.5% by mass percent composition, the coupling agent (30% silane coupling agent and 70% titanate coupling agent) that mass percent composition is placed on high-speed stirrer and mix at temperature Stirring at 90°C for 5 minutes;

[0037] Add PP (melt flow rate 18g / 10min) with a mass percentage of 90%, a dispersant with a mass percentage of 1.5%, and an antioxidant with a mass percentage of 2%, at a temperature of 50°C Stir for 3 minutes to obtain a polypropylene composite material precursor;

[0038] Add the polypropylene composite material precursor to the hopper of the twin-screw extruder, the temperature in the first zone: 120-130°C; the temperature in the second zone: 130-140°C; the temperature in the third zone: 140-150°C; the temperature in the fourth zone : 140~170℃; temperature in zone five: 140~170℃; temperature in zone six: 140~170℃; temperature in zone seven: 140~170℃; temperature in zone eight: 150~160℃; temperature ...

Embodiment 2

[0040] The nano silicon dioxide that mass percent composition is 0.7%, the coupling agent (50% silane coupling agent and 50% titanate coupling agent) that mass percent composition is 1.3% are placed in high-speed stirrer and mix, in Stirring for 8 minutes at a temperature of 100°C;

[0041]Add PP (melt flow rate 18g / 10min) with a mass percentage of 96%, a dispersant with a mass percentage of 1.5%, and an antioxidant with a mass percentage of 2%, at a temperature of 80°C Stir for 4 minutes to obtain a polypropylene composite material precursor;

[0042] Add the polypropylene composite material precursor to the hopper of the twin-screw extruder, the temperature in the first zone: 120-130°C; the temperature in the second zone: 130-140°C; the temperature in the third zone: 140-150°C; the temperature in the fourth zone : 140~170℃; temperature in zone five: 140~170℃; temperature in zone six: 140~170℃; temperature in zone seven: 140~170℃; temperature in zone eight: 150~160℃; tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com