High performance aluminium alloy high voltage power cable

A high-voltage power, aluminum alloy technology, used in power cables, power cables with shielding/conductive layers, insulated cables, etc., can solve problems that need to be improved, and achieve enhanced wear resistance, wear resistance and heat resistance. , good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

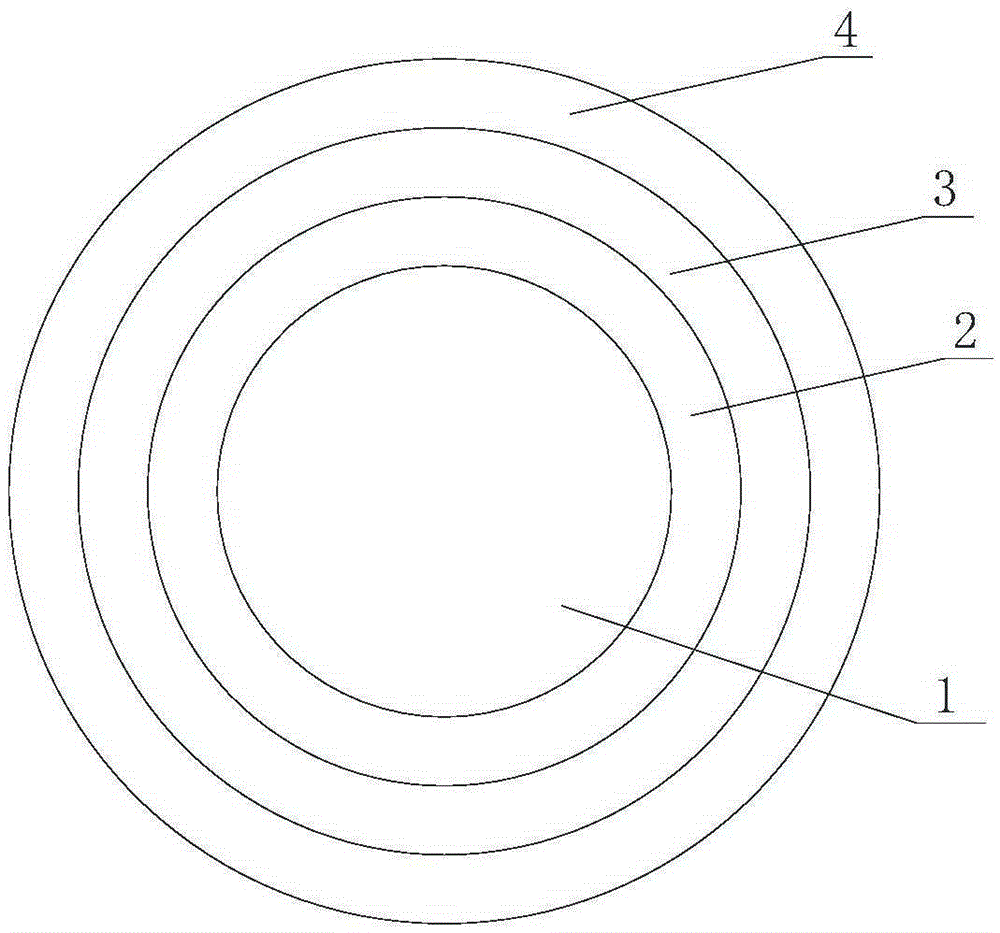

[0017] refer to figure 1 , a high-performance aluminum alloy high-voltage power cable, including a wire core 1, an insulating layer 2, a shielding layer 3, and a sheath layer 4; the insulating layer 2 is wrapped around the wire core 1, and the shielding layer 3 is wrapped around the insulating layer 2 The sheath layer 4 is covered outside the shielding layer 3; the wire core 1 is made of heat-resistant aluminum alloy wire, and the sheath layer 4 is made of modified nitrile rubber.

[0018] The raw materials of the modified nitrile rubber material include by weight: 40 parts of nitrile rubber, 15 parts of 2,4-toluene diisocyanate trimer, 12 parts of isocyanate-terminated polyurethane prepolymer, and 1.5 parts of dicumyl peroxide , 1 part of stearic acid, 3 parts of antimony trioxide, 0.2 parts of butyl phthalate, 1.8 parts of disproportionated rosin, 0.8 parts of oleic acid, 10101.8 parts of antioxidant, 0.2 part of antioxidant DLTDP, antioxidant 2 parts of DTDTP, 1 part of li...

Embodiment 2

[0020] refer to figure 1 , a high-performance aluminum alloy high-voltage power cable, including a wire core 1, an insulating layer 2, a shielding layer 3, and a sheath layer 4; the insulating layer 2 is wrapped around the wire core 1, and the shielding layer 3 is wrapped around the insulating layer 2 The sheath layer 4 is covered outside the shielding layer 3; the wire core 1 is made of heat-resistant aluminum alloy wire, and the sheath layer 4 is made of modified nitrile rubber.

[0021] The raw materials of the modified nitrile rubber material include by weight: 80 parts of nitrile rubber, 5 parts of 2,4-toluene diisocyanate trimer, 20 parts of isocyanate-terminated polyurethane prepolymer, and 0.5 part of dicumyl peroxide , 2 parts of stearic acid, 1 part of antimony trioxide, 0.8 parts of butyl phthalate, 1 part of disproportionated rosin, 1.4 parts of oleic acid, 10101.2 parts of antioxidant, 0.9 part of antioxidant DLTDP, antioxidant 1 part of DTDTP, 5 parts of liquid ...

Embodiment 3

[0023] refer to figure 1 , a high-performance aluminum alloy high-voltage power cable, including a wire core 1, an insulating layer 2, a shielding layer 3, and a sheath layer 4; the insulating layer 2 is wrapped around the wire core 1, and the shielding layer 3 is wrapped around the insulating layer 2 The sheath layer 4 is covered outside the shielding layer 3; the wire core 1 is made of heat-resistant aluminum alloy wire, and the sheath layer 4 is made of modified nitrile rubber.

[0024] The raw materials of the modified nitrile rubber material include by weight: 78 parts of nitrile rubber, 8 parts of 2,4-toluene diisocyanate trimer, 18 parts of isocyanate-terminated polyurethane prepolymer, and 1 part of dicumyl peroxide , 1.5 parts of stearic acid, 2 parts of antimony trioxide, 0.6 parts of butyl phthalate, 1.2 parts of disproportionated rosin, 1.3 parts of oleic acid, 10101.4 parts of antioxidant, 0.8 part of antioxidant DLTDP, antioxidant 1.5 parts of DTDTP, 4 parts of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com