Copper wire online annealing apparatus for communication cable

A communication cable and copper wire technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve problems affecting product quality, uneven toughness, waste of copper wire, etc., to improve work efficiency and product quality, The effect of good elongation and soft copper wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

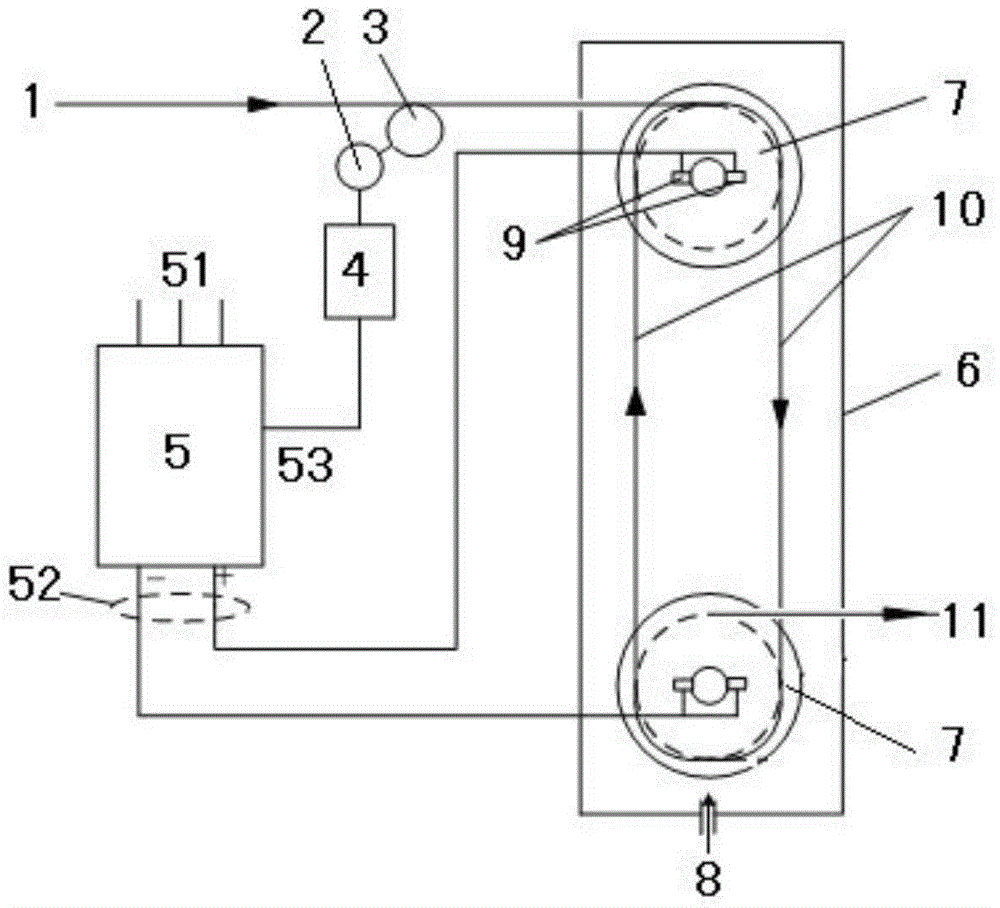

[0014] attached figure 1 It is the copper wire online tempering device for communication cables according to the present invention, which includes a cabin body 6 and a controllable DC power supply system; the cabin body 6 is provided with two conductive wheels 7 that are spaced up and down and whose end faces are evenly arranged; The conductive wheel 7 is connected with the cabin body 6 through a shaft; a carbon brush 9 is arranged on the shaft; an insulator is arranged between the conductive wheel 7 and the shaft and the cabin body 6 to prevent leakage; the controllable DC power supply system includes The tachometer generator 2, the tachometer guide wheel 3, the square root operation circuit 4 and the three-phase adjustable rectifier 5; the three-phase adjustable rectifier 5 rectifies the three-phase alternating current on the three-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com