Commercial light truck tire

A technology for trucks and automobile tires, which is applied to heavy tires, heavy vehicles, tire parts, etc., and can solve the problems of multi-pitch design with unequal proportions, non-parallel tire circumferential direction, poor drainage performance, etc. problems, to achieve the effect of dissipating heat, softening the tread, and good anti-skid performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

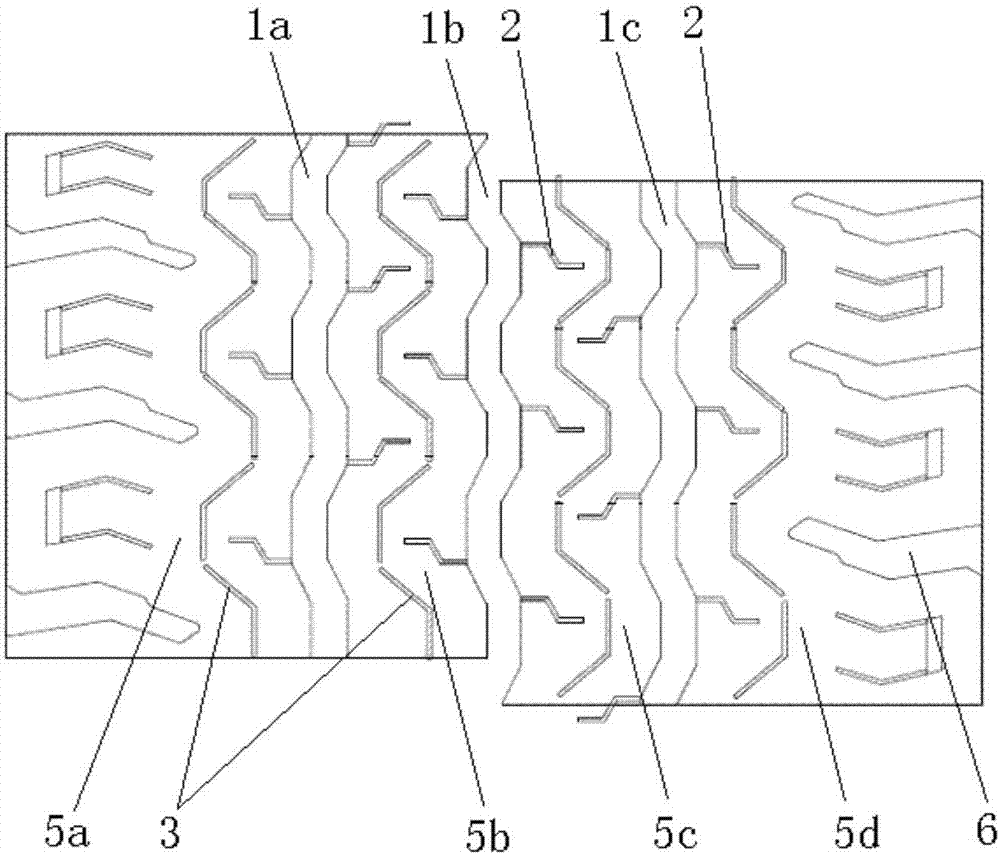

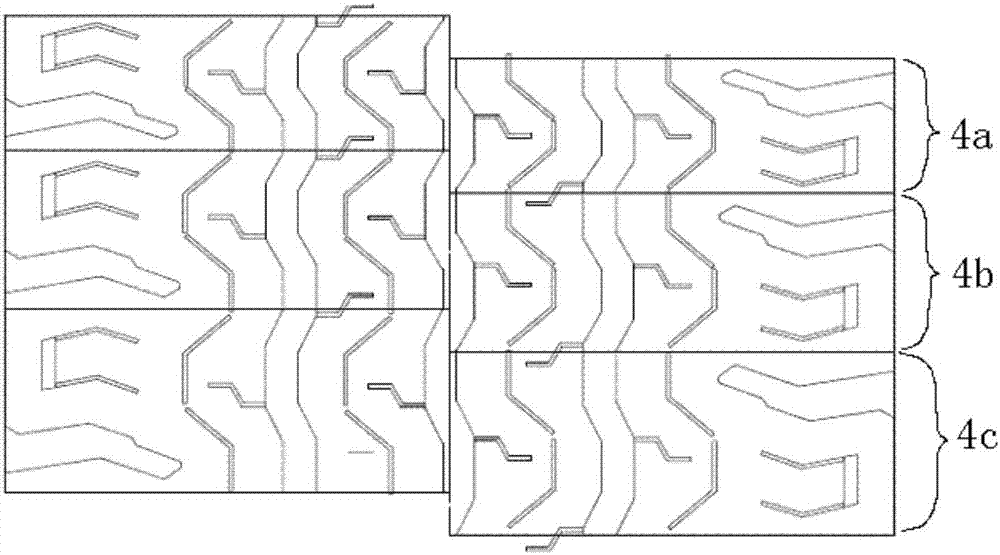

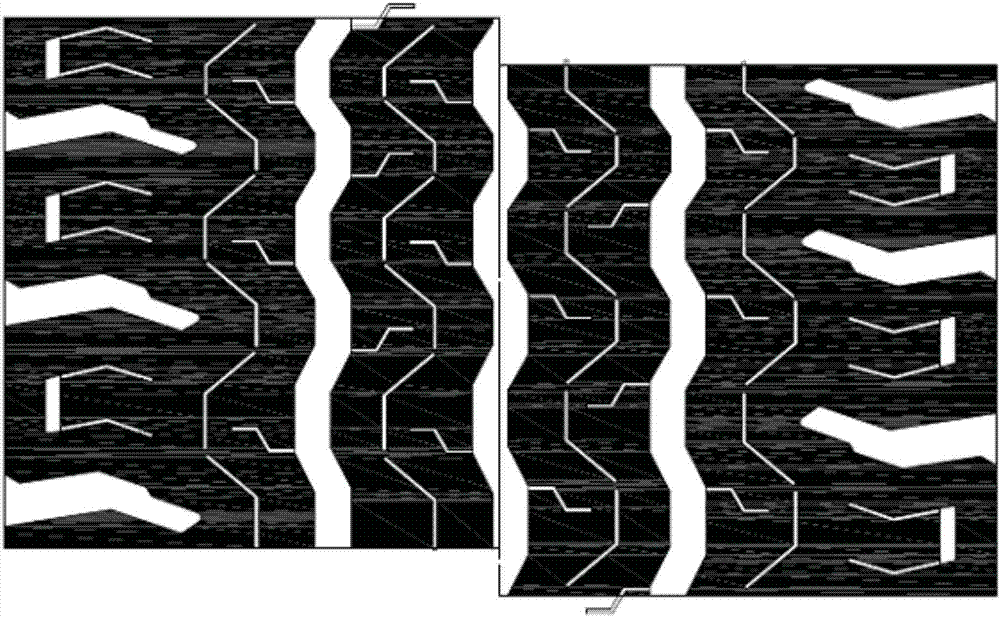

[0031] In order to achieve the purpose of the present invention, figure 1 A partially developed plan view of a tread portion according to an embodiment of the present invention is shown. The tread pattern of this invention is circumferentially continuous in the vertical direction in the drawing. The tire tread has a first circumferential main groove 1a, a second circumferential main groove 1b, and a third circumferential main groove 1c. These three circumferential main grooves are all in the shape of a broken line. The separation between the three circumferential main grooves and the inner and outer shoulders of the tire constitutes the first The circumferential pattern block 5a, the second circumferential pattern block 5b, the third circumferential pattern block 5c, and the fourth circumferential pattern block 5d, each circumferential pattern block has a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com