Inflatable radial ply tyre for over loading

A radial tire, tire technology, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve problems such as low traction, improve braking force and driving force, improve durability, and prevent peeling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The pattern structure of the heavy-duty pneumatic radial tire of the present invention will be described in detail below with reference to the accompanying drawings.

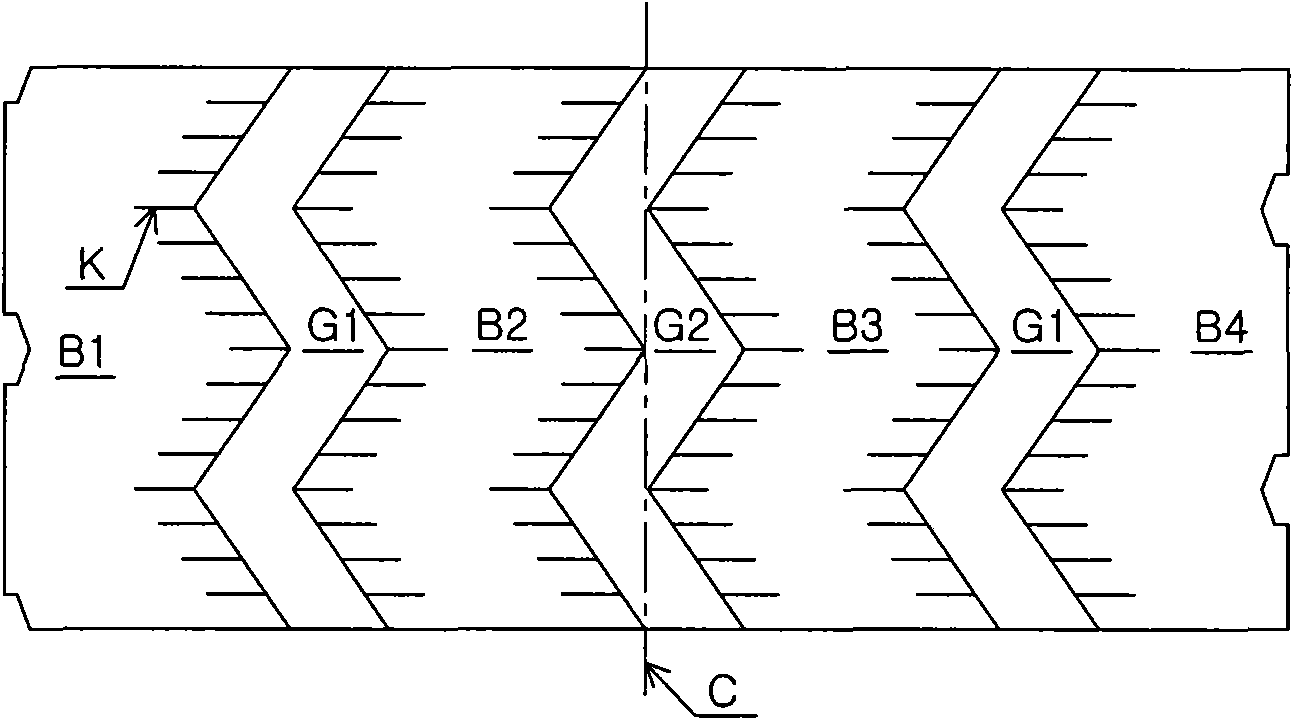

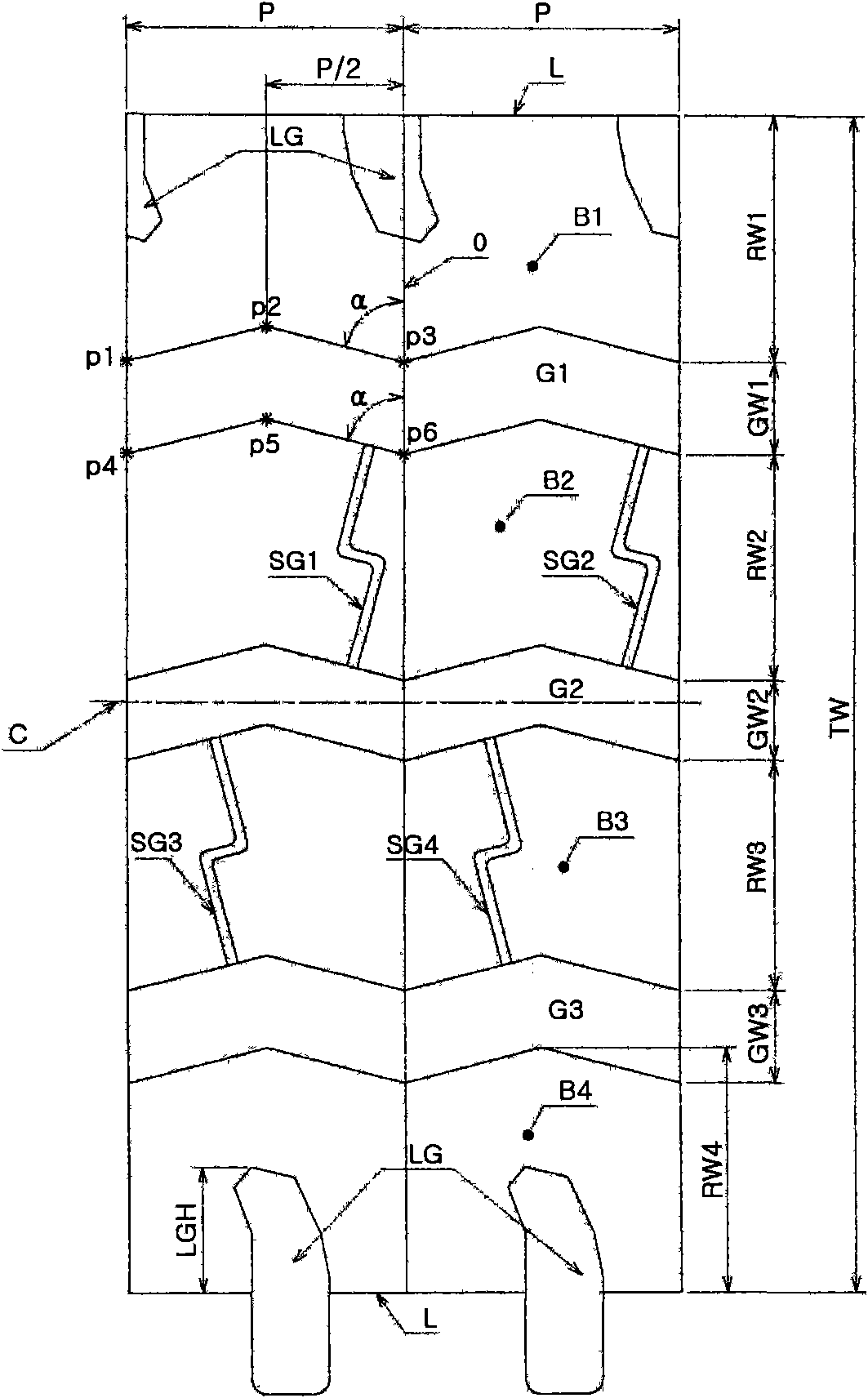

[0027] The tread of the pneumatic radial tire for heavy load according to the present invention has a zigzag 4-rib pattern. Here, if figure 2 As shown, "zigzag 4-rib pattern" means that it is divided by 4 pattern blocks B1, B2, B3, B4 and 3 longitudinal grooves G1, G2, G3, and the overall shape of the pattern block and the longitudinal groove is along the The circumferential direction (travel direction) of the tire forms a zigzag shape.

[0028] The longitudinal grooves G1, G2, G3 consist of a central groove G2 formed at the center of the contact surface (ie, tread) of the tire and side grooves G1, G3 formed on both sides thereof, and are repeatedly formed in a zigzag shape. In the drawings, the symbol "C" indicates the centerline of the tire in the circumferential direction.

[0029] The pattern bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com