DC stepping permanent magnetism straight line motor drive type oil-submersible extracting pump

A permanent magnet linear motor and driven technology, which is applied in the direction of electric components, machines/engines, pumps, etc., can solve the problems of short service life of electric pumps, heavy workload, low motor efficiency, etc., and achieve low energy consumption and failure rate , reduced operating costs, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The implementation of the present invention will be further described below in conjunction with the accompanying drawings.

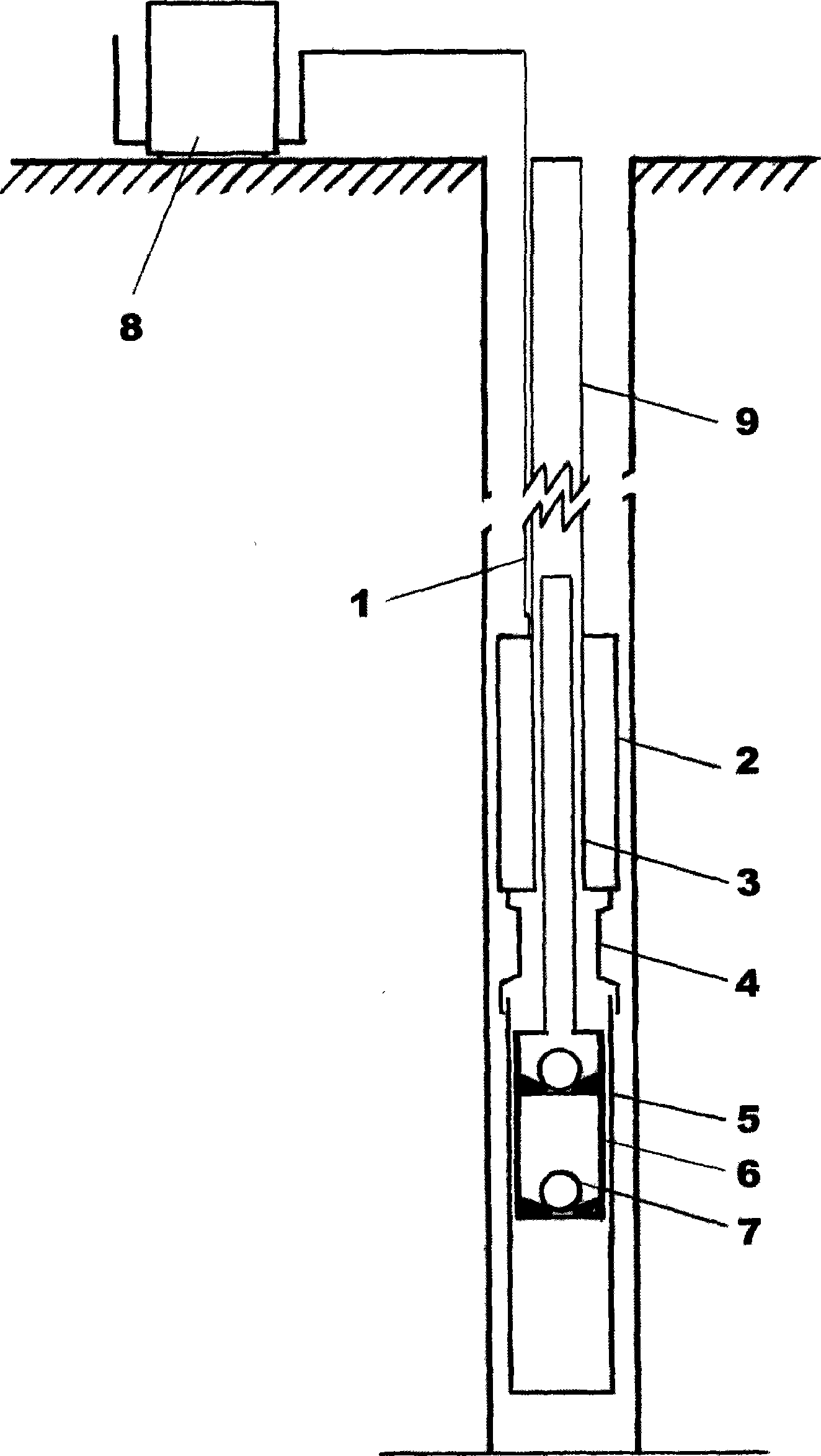

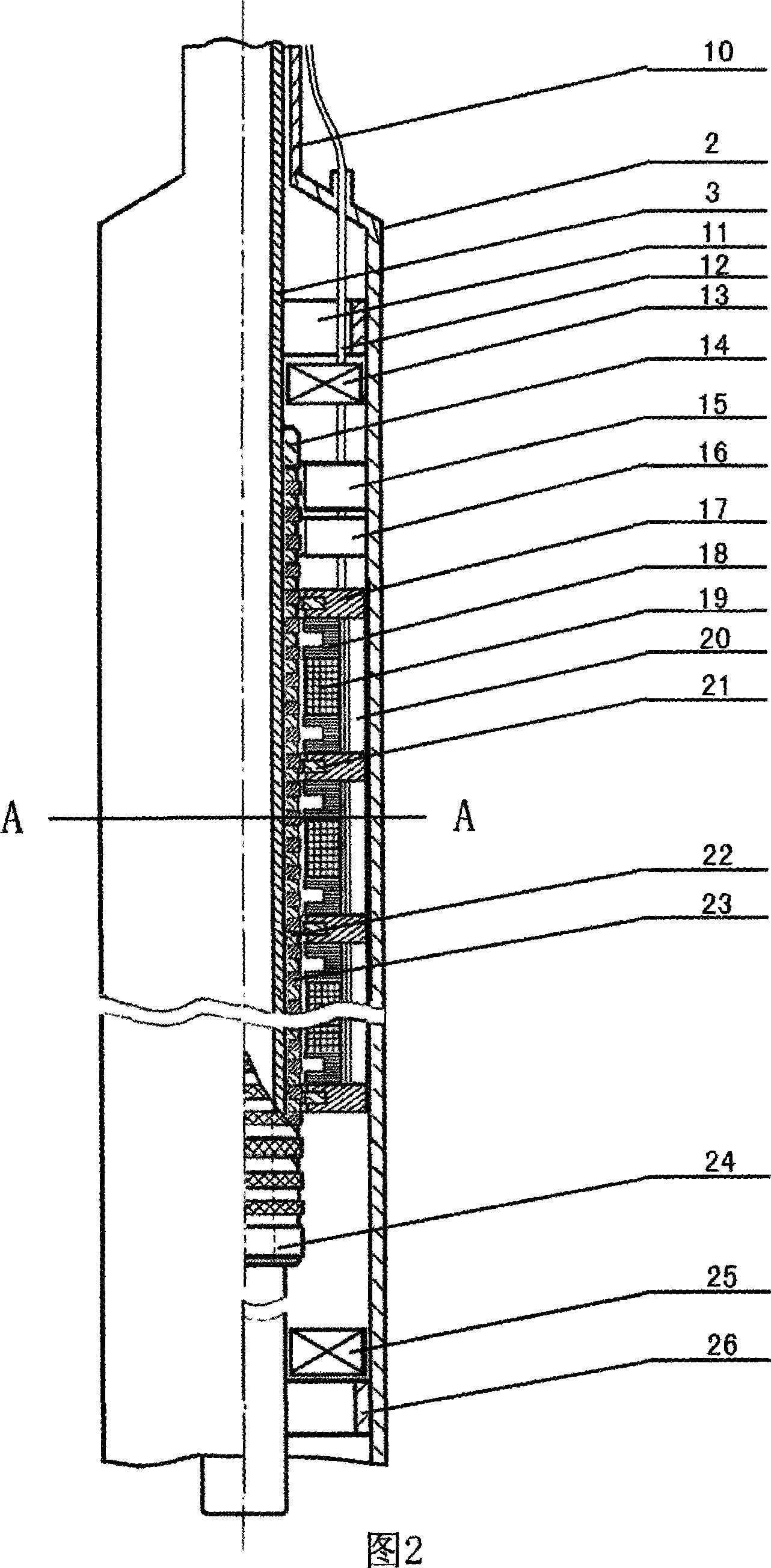

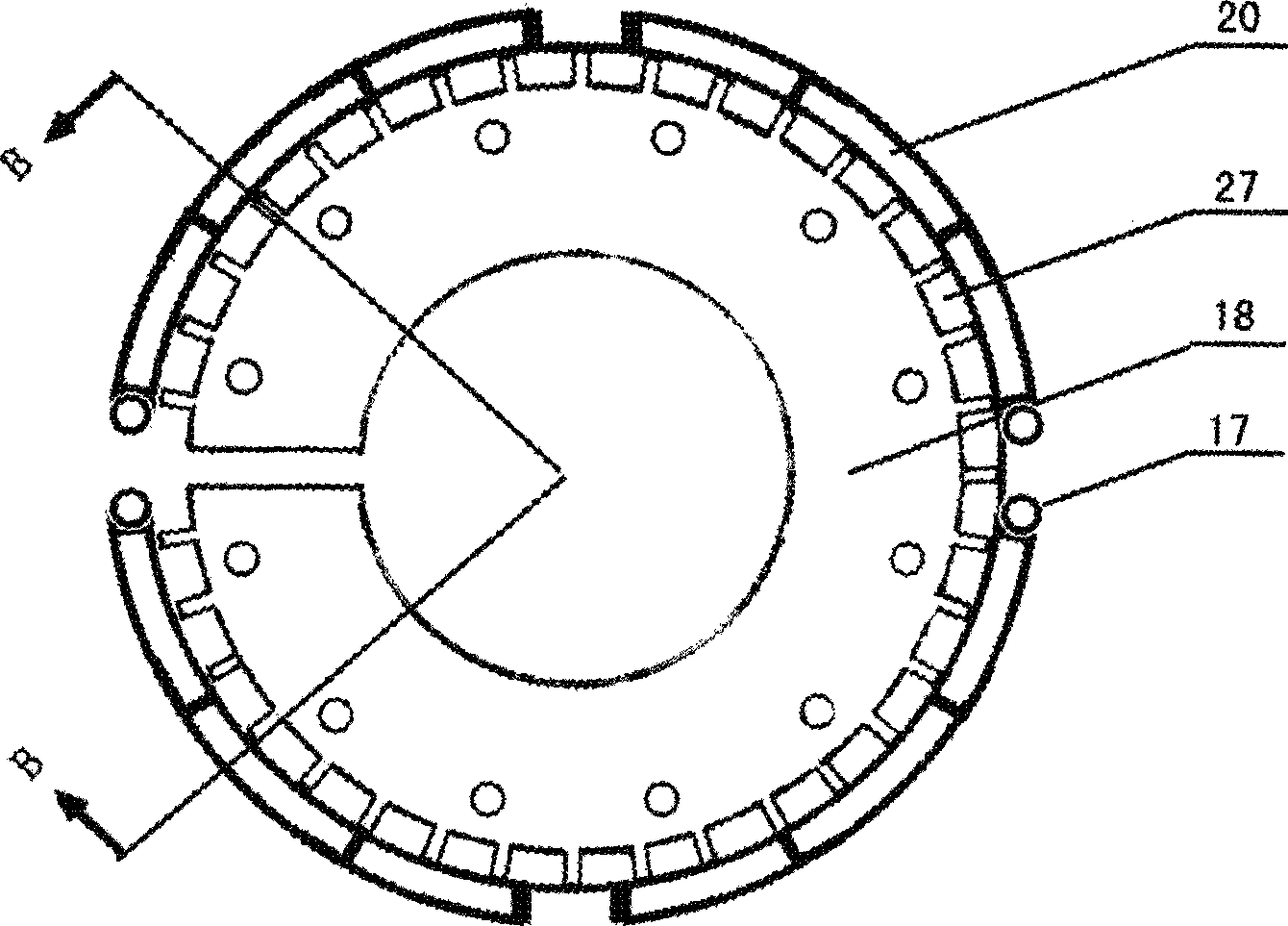

[0011] Such as figure 1 As shown, the present invention is made up of cable 1, motor barrel 2, motor mover 3, reducing sheath 4, pump barrel 5, plunger 6, ball valve group 7, and its structural assembly relationship is as follows: the upper and lower ends of cable 1 are respectively connected with The ground control cabinet 8 is connected to the coil in the motor barrel 2, the upper and lower ends of the motor barrel 2 are respectively connected with the oil pipe 9 and the variable diameter sheath 4 with threads, and the lower end of the variable diameter sheath 4 is connected with the pump barrel 5 with threads, The motor cylinder 2 and the pump cylinder 5 are respectively provided with a motor mover 3 , a plunger 6 and a ball valve group 7 , and the lower end of the motor mover 3 is connected with the upper end of the plunger 6 . Among them, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com