Metering pump with entire solid eccentric wheel travel adjustment mechanism

A technology of integral eccentric wheel and stroke adjustment, applied in the field of metering pumps, can solve the problems of large fluctuation in metering accuracy, complex structure, and insufficient service life, and achieve the effects of improving bearing capacity, high metering accuracy, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

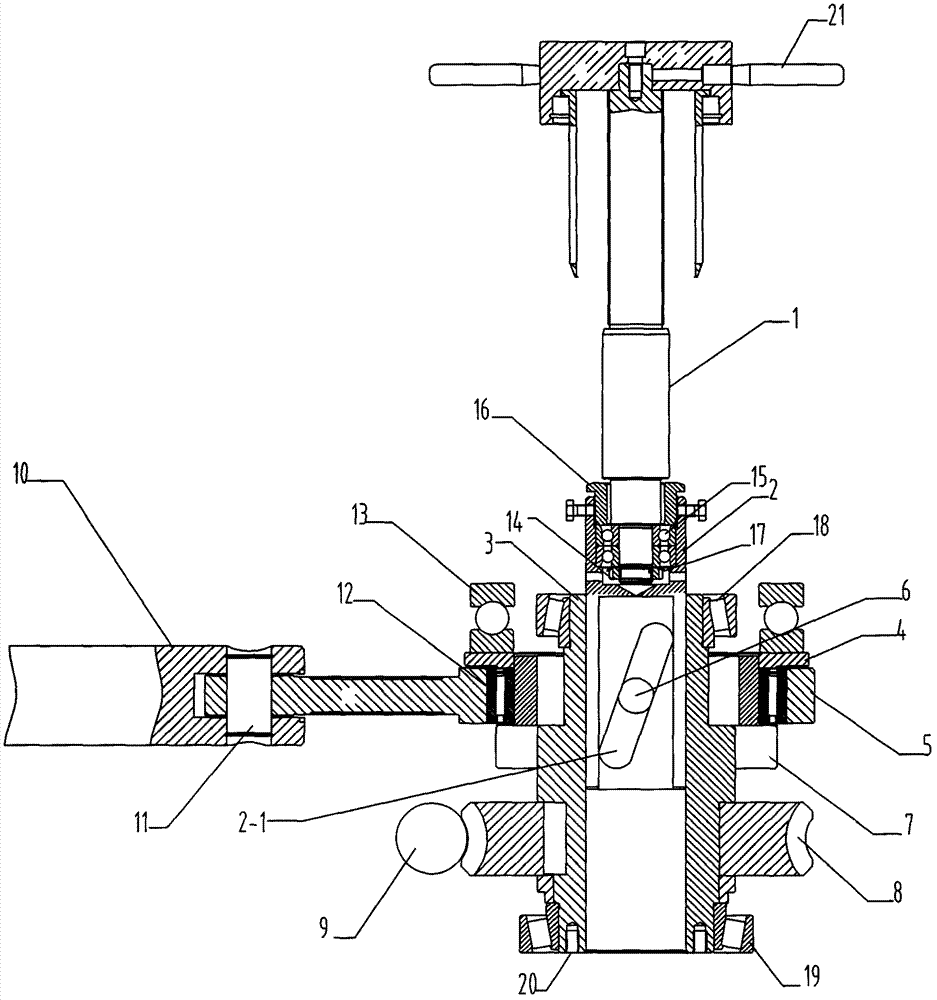

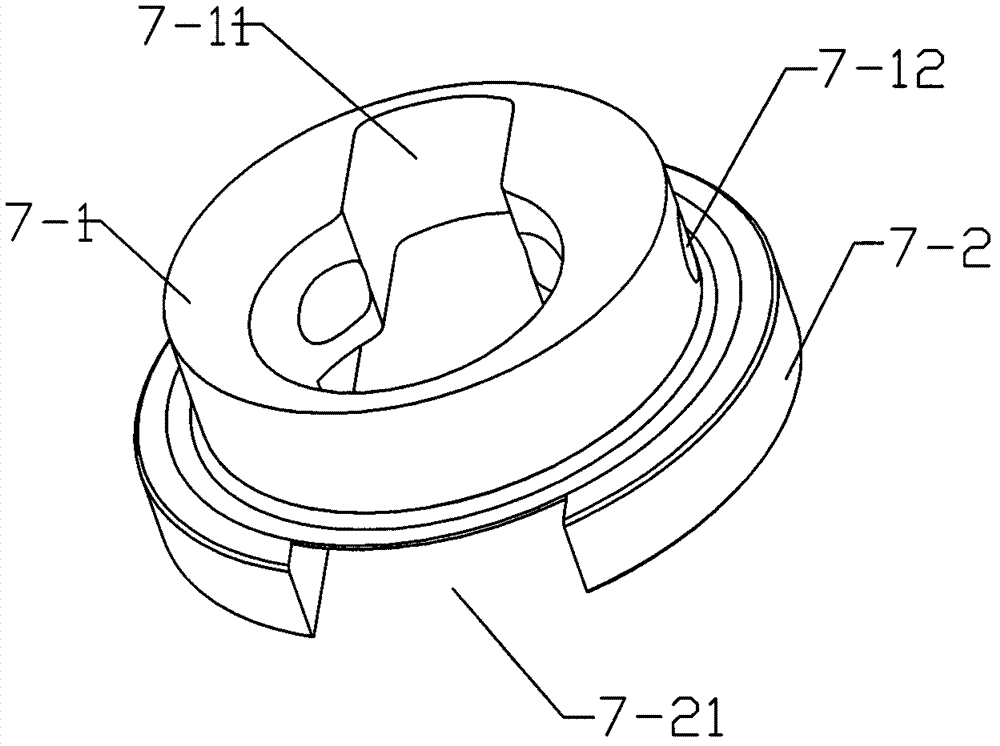

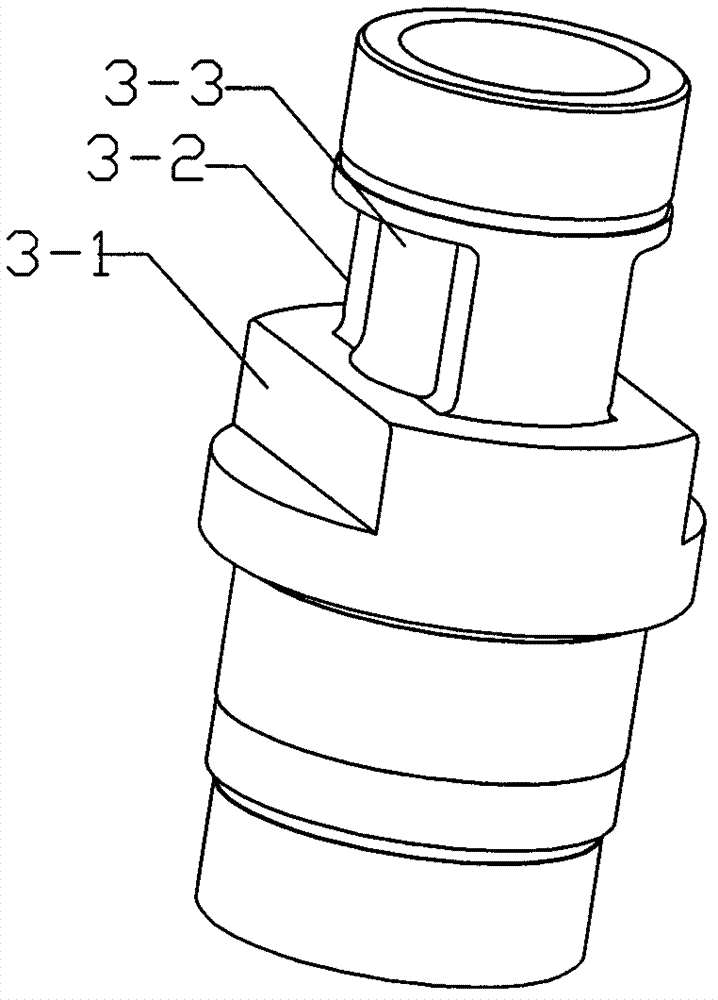

[0024] like figure 1 The sliding rod stroke adjustment mechanism shown includes an adjusting screw 1, a moving shaft 2, a hollow shaft 3, a connecting rod 5, an integral eccentric wheel 7, a worm wheel 8, a worm 9, and a sliding rod 10. The adjusting screw 1 One end of the moving shaft 2 can be connected to the coaxial relative rotation, the moving shaft 2 is inserted into the hollow shaft 3, the moving shaft 2 is provided with a chute 2-1, and the chute 2-1 is provided with The slider 6, the hollow shaft 3 is covered with an integral eccentric wheel 7, the integral eccentric wheel 7 is fixed to the connecting rod 5, the connecting rod 5 is connected to the sliding rod 10, and the hollow shaft 3 A worm wheel 8 is sleeved on the top, and the worm wheel 8 is engaged with the worm 9 .

[0025] Described adjusting screw mandrel 1 passes through round nut 14, lock plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com