Coiler

A winder and guide plate technology, applied in the direction of fixing labels, labels, external supports, etc., can solve the problems of bobbin deformation, small contact area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

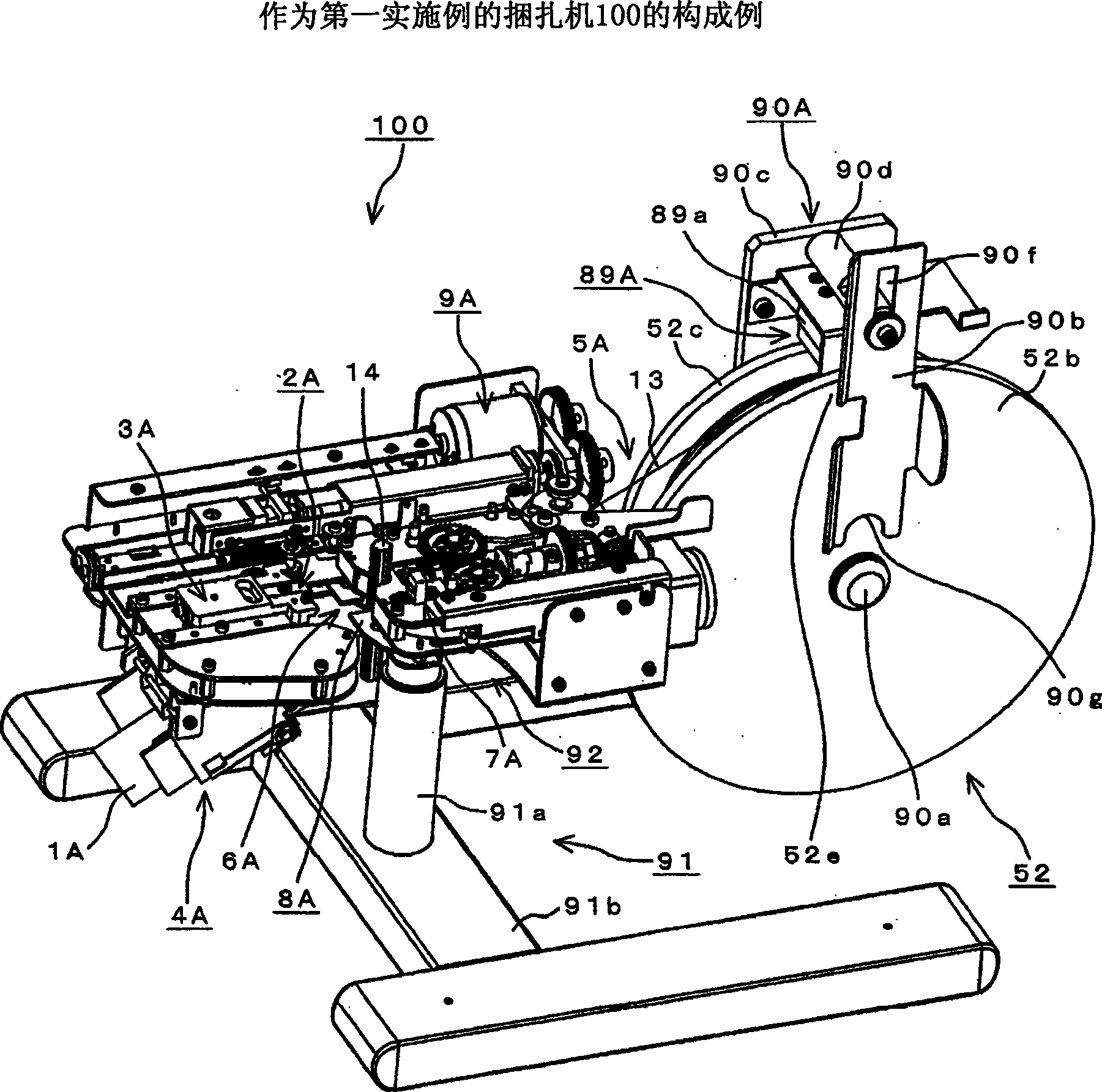

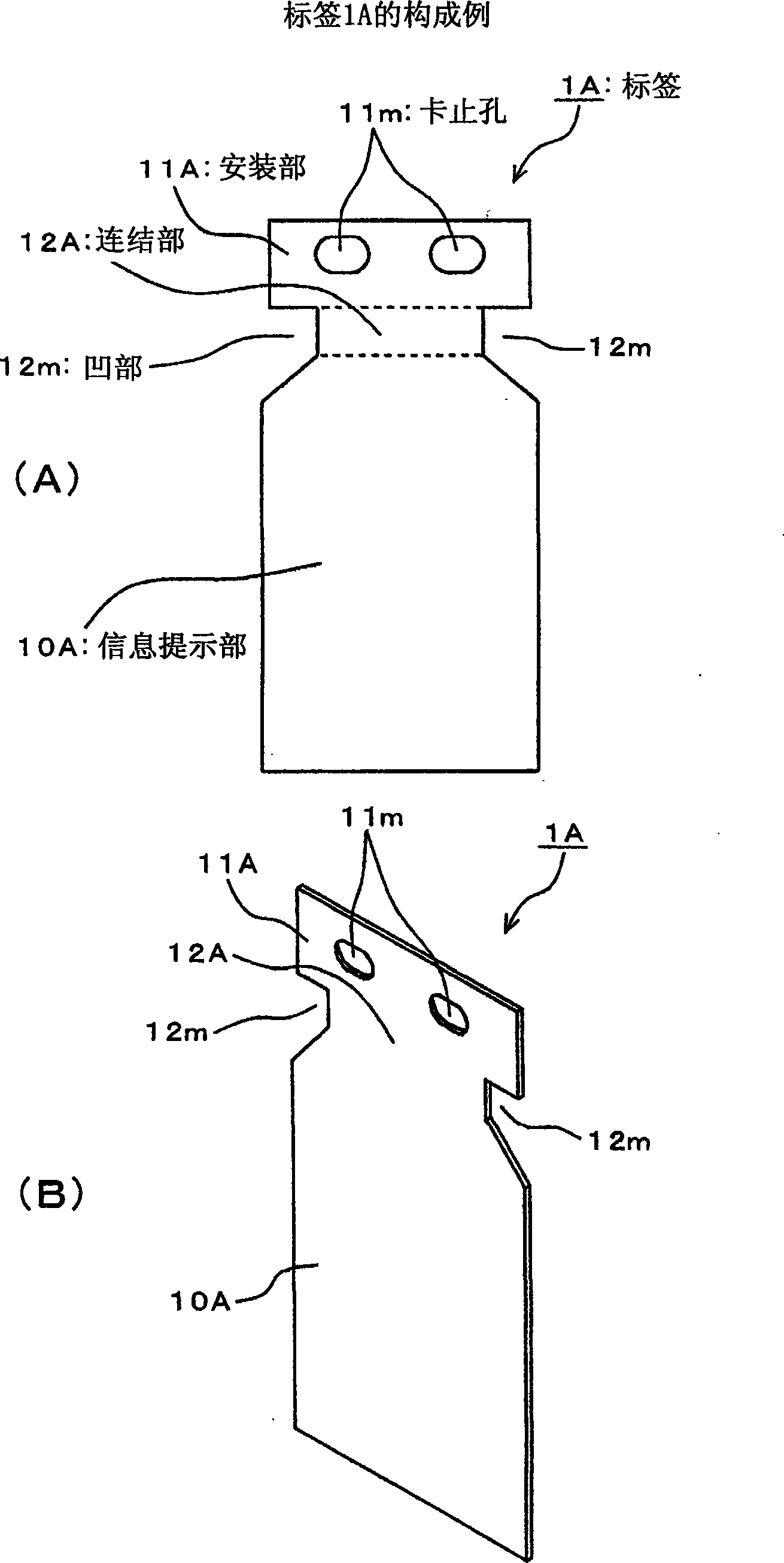

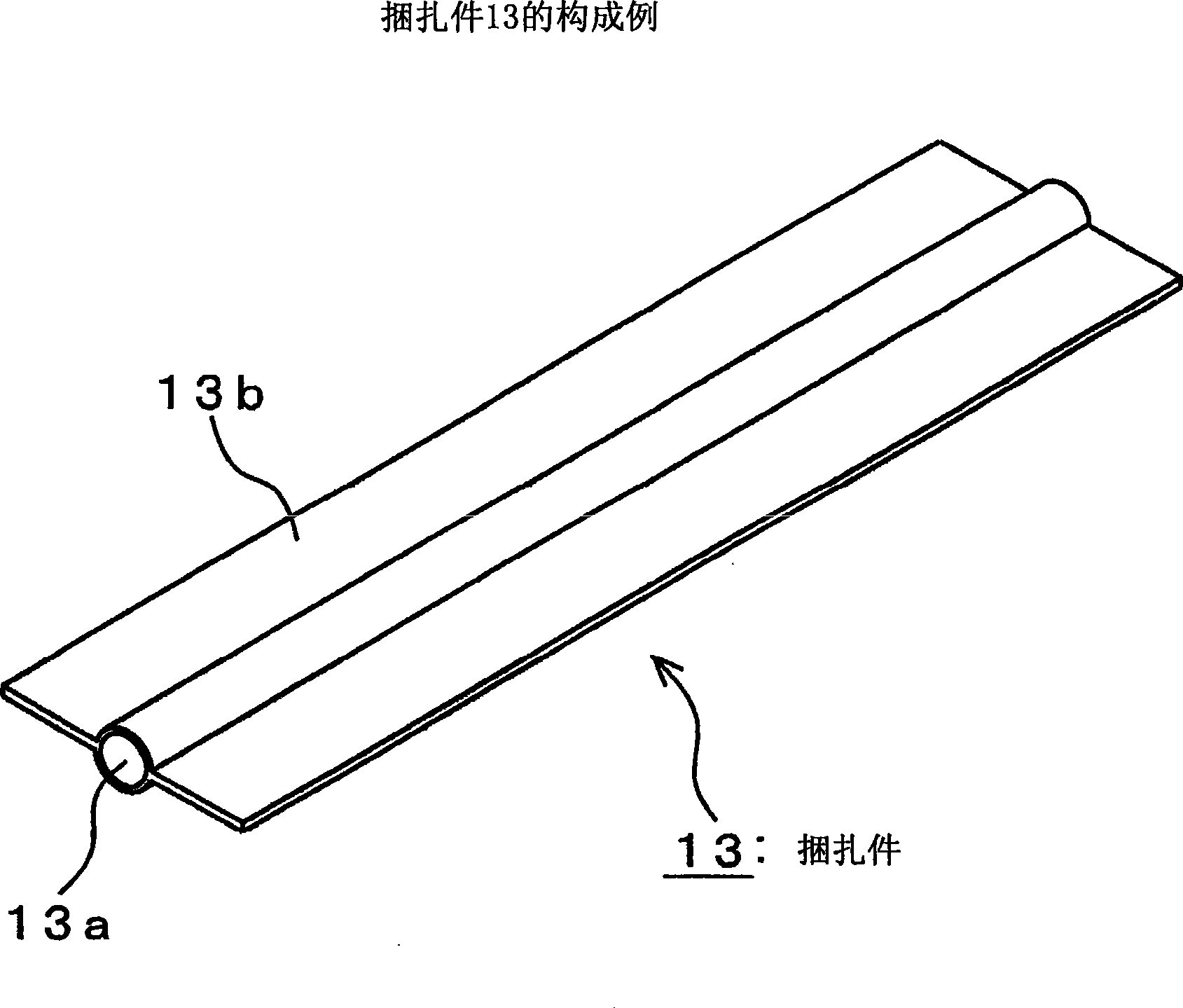

[0083] figure 1 It is a perspective view which shows the structural example of the binding machine 100 which is 1st Example of this invention. figure 1 The shown binding machine 100 uses the two locking holes provided on the label 1A, etc., to pass a band-shaped binding member 13 such as a cable tie, and at the same time, wrap the binding member 13 around the bag with the mouth tightly closed. 14 etc. (refer to Figure 5 ) to attach the label. The bag 14 constitutes an example of a loaded object. As the binding member 13, strings, metal wires, etc. are used in addition to cable ties.

[0084] The binding machine 100 is provided with the main body frame part 92 which comprises a main body part, and the support part 91 which supports this main body frame part 92. As shown in FIG. The support part 91 is comprised from the support stand 91b of "H" shape, and the support|pillar 91a vertically attached to this support stand 91b. The main body frame part 92 is attached to the ...

Embodiment 2

[0397] Figure 59 It is a partially enlarged perspective view showing a configuration example of a label spring loading mechanism 2A' of the binding machine 200 as the second embodiment.

[0398] Figure 59 The illustrated strapping machine 100 is provided with a tag spring loading mechanism 2A'. The label spring loading mechanism 2A' is equipped with a pair of torsion spring (Neuribane) members 21, 22 constituting one example of the push-in member, which are pressed from both sides to the binding member fastening mechanism from the label conveying mechanism 4A via the label holding mechanism 3A. 7A operates in such a way that the side end of the label 1A conveyed by the binder forming mechanism 6A is adjacent.

[0399] In this example, the upper end of the label 1A is held by the label carrying member 30e provided at a predetermined position from the upper part of the label holding mechanism 3A to the binder passage 303, and at the same time, the side ends of the label 1A a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com