Automatic stamping machine and stamping method thereof

A punching machine, automatic technology, applied in punching machines, presses, manufacturing tools, etc., can solve the problems of incoordination of consciousness, hand injury by punching machine, injury by punching machine, etc., to eliminate safety accidents, enhance safety, prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

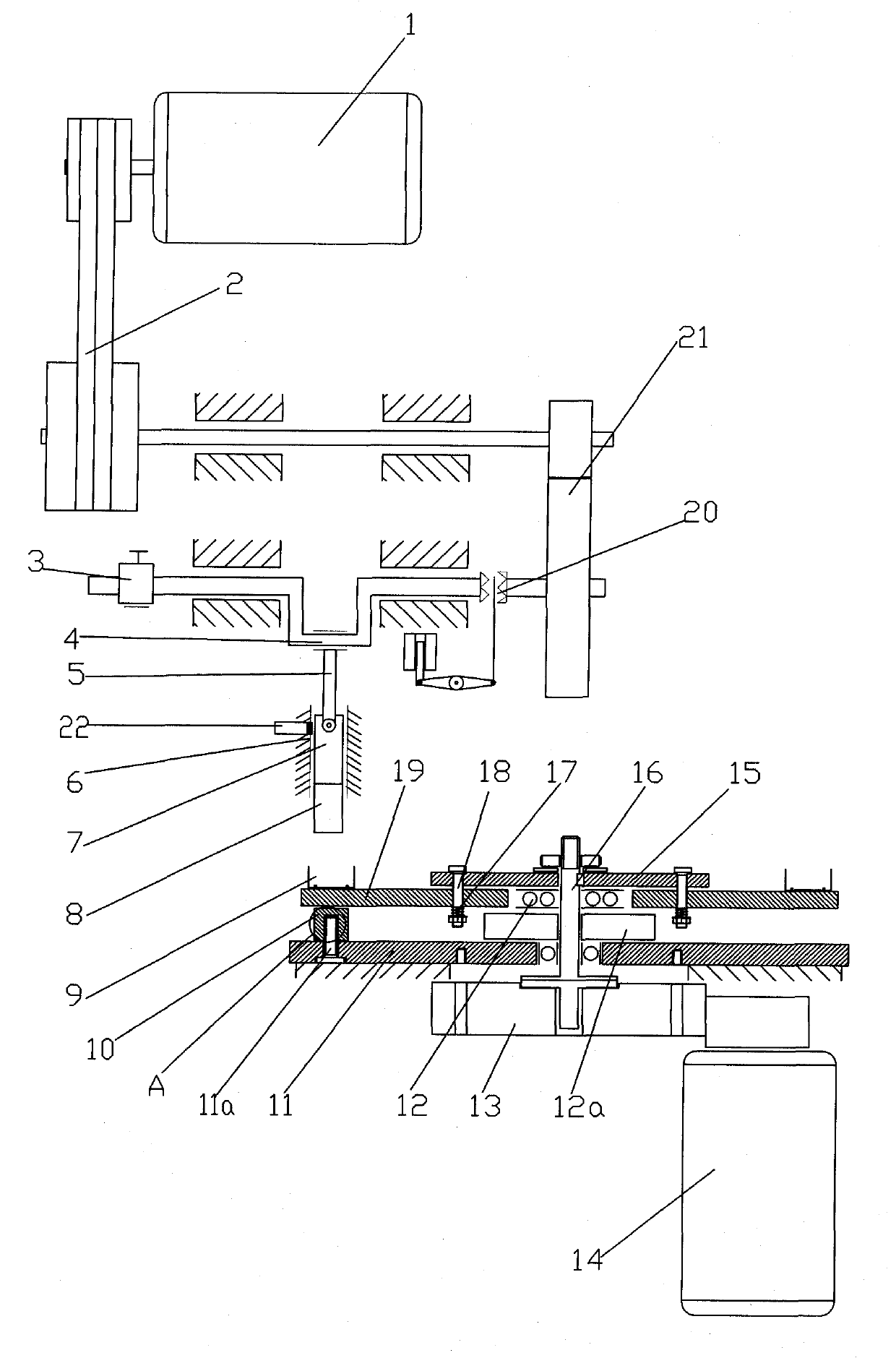

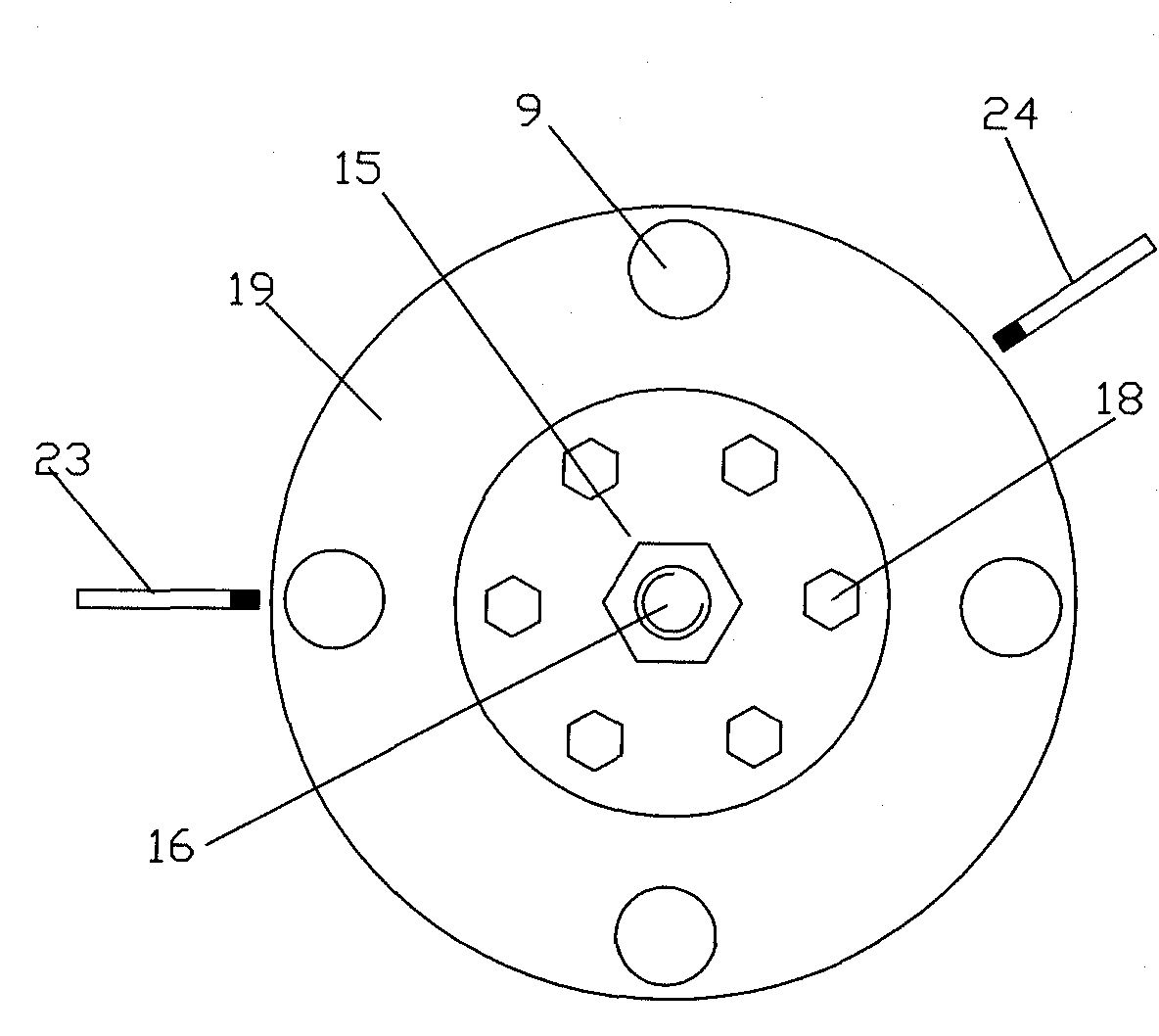

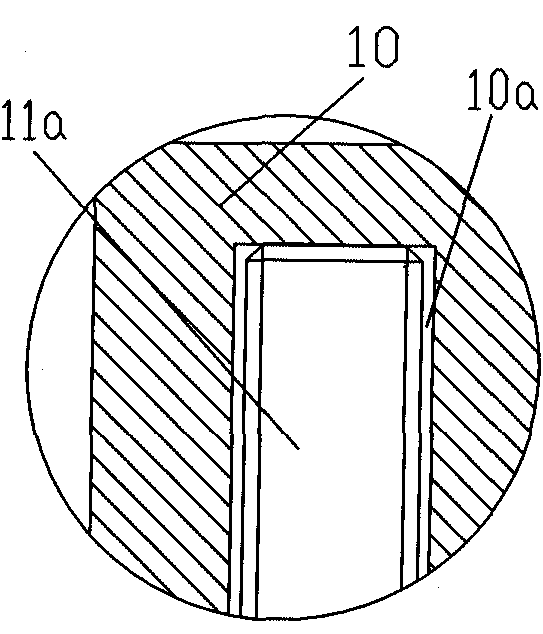

[0028] figure 1 It is a structural schematic diagram of the present invention, figure 2 is the top view of the turntable, image 3 for figure 1 Enlarged view at A, Figure 4 It is a block diagram of the automatic control principle of the present invention, as shown in the figure: the automatic stamping machine tool of the present embodiment includes an upper mold assembly and a lower mold assembly, and the upper mold assembly includes an upper mold 8 and an upper mold driving device. The lower mold assembly includes a lower mold 9 and a lower mold driving device. The lower mold driving device includes a turntable assembly and a turntable drive motor 14. The turntable assembly includes a base 11 and a turntable that is rotatably matched with the base 11 on a horizontal plane. Described turntable comprises central disc 15 and annular bearing platform 19, and the rotor shaft of turntable driving motor 14 is driven to cooperate with the mode that can make central disc 15 rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com