Tire vulcanizing apparatus

A tire vulcanization and tire technology, which is applied to tires, other household appliances, household appliances, etc., can solve the problems of time and labor, and the inability to ensure the accuracy of the abutting part, so as to prevent partial wear, shorten processing time, manufacture and install easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

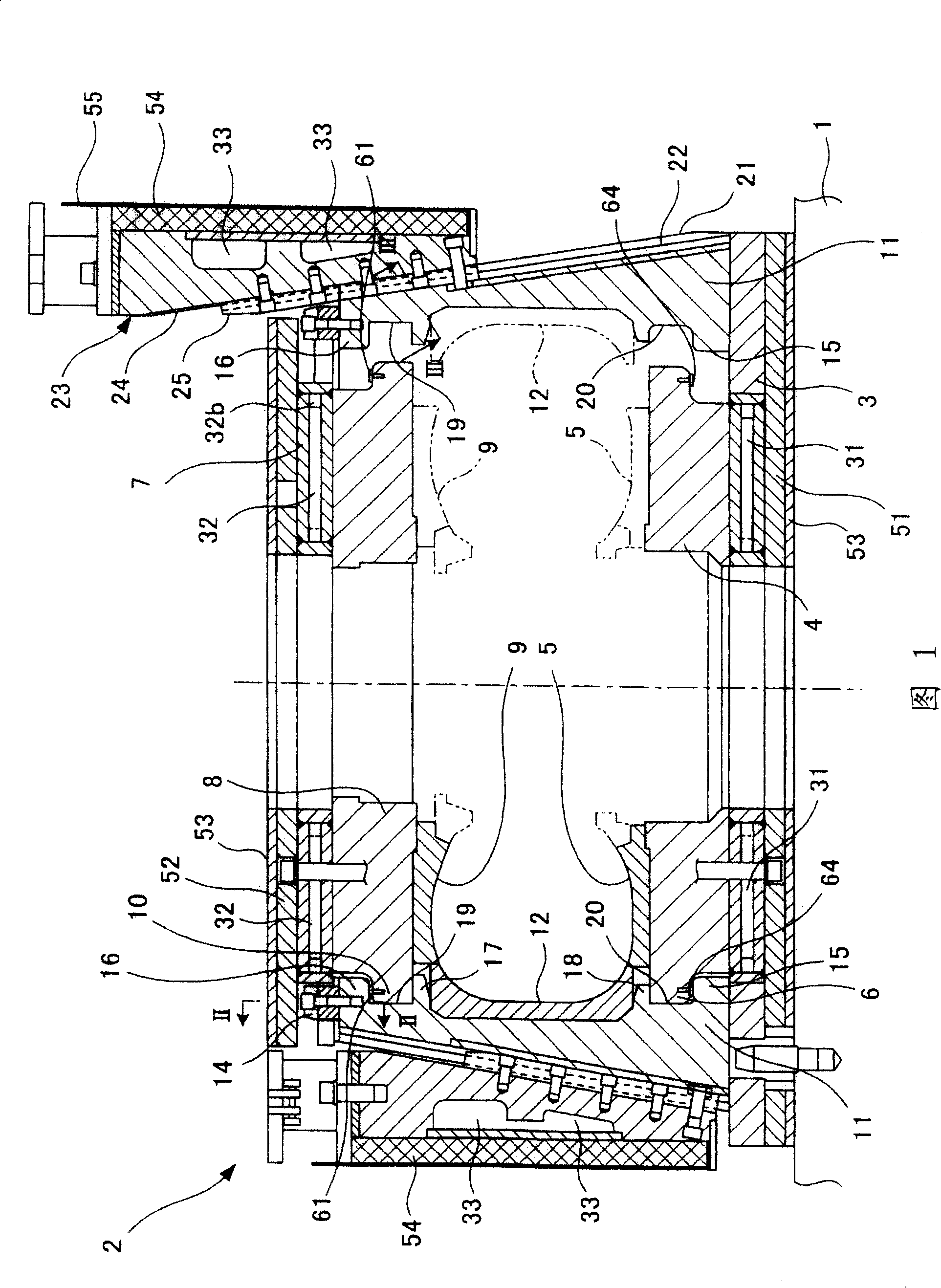

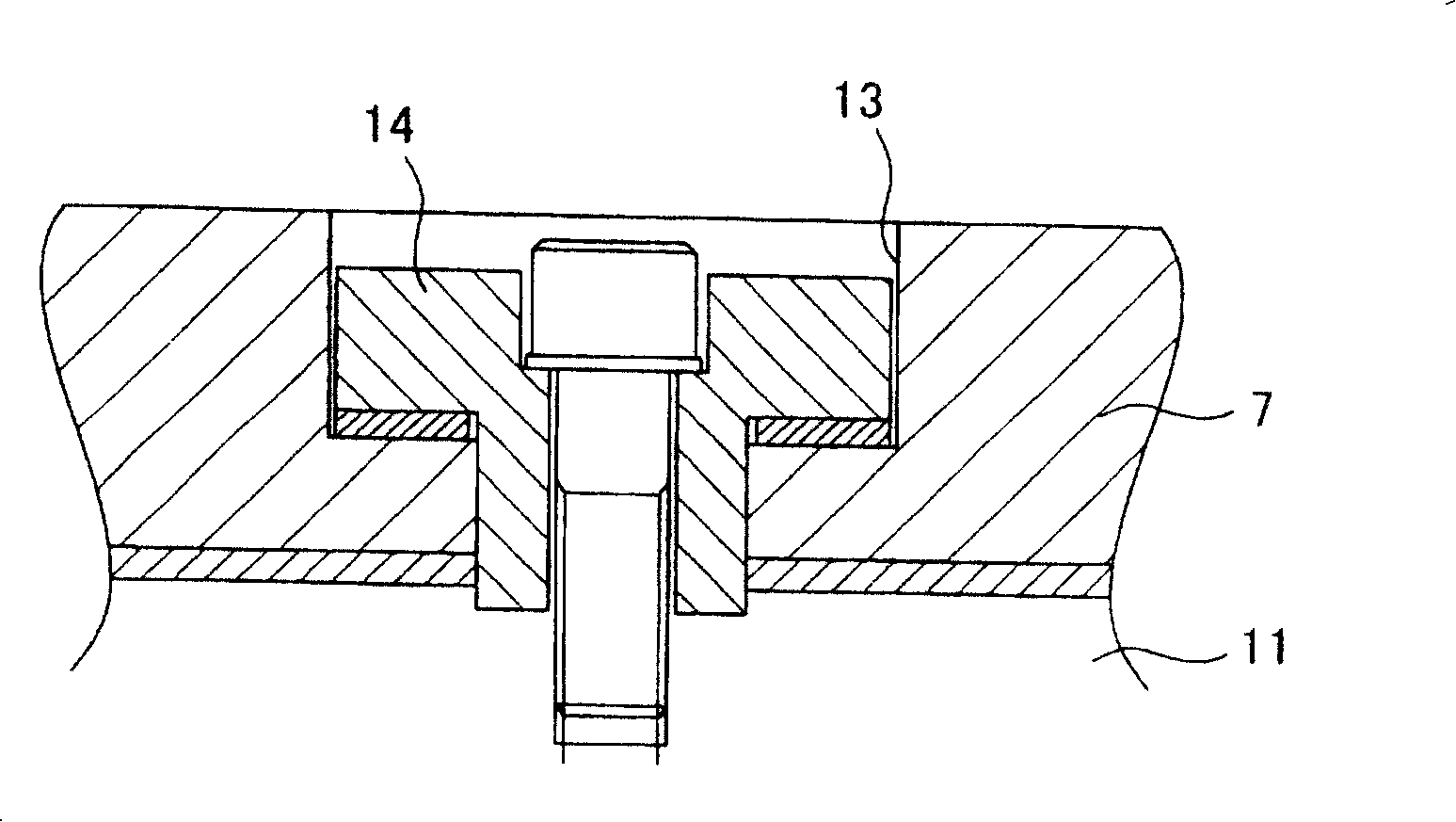

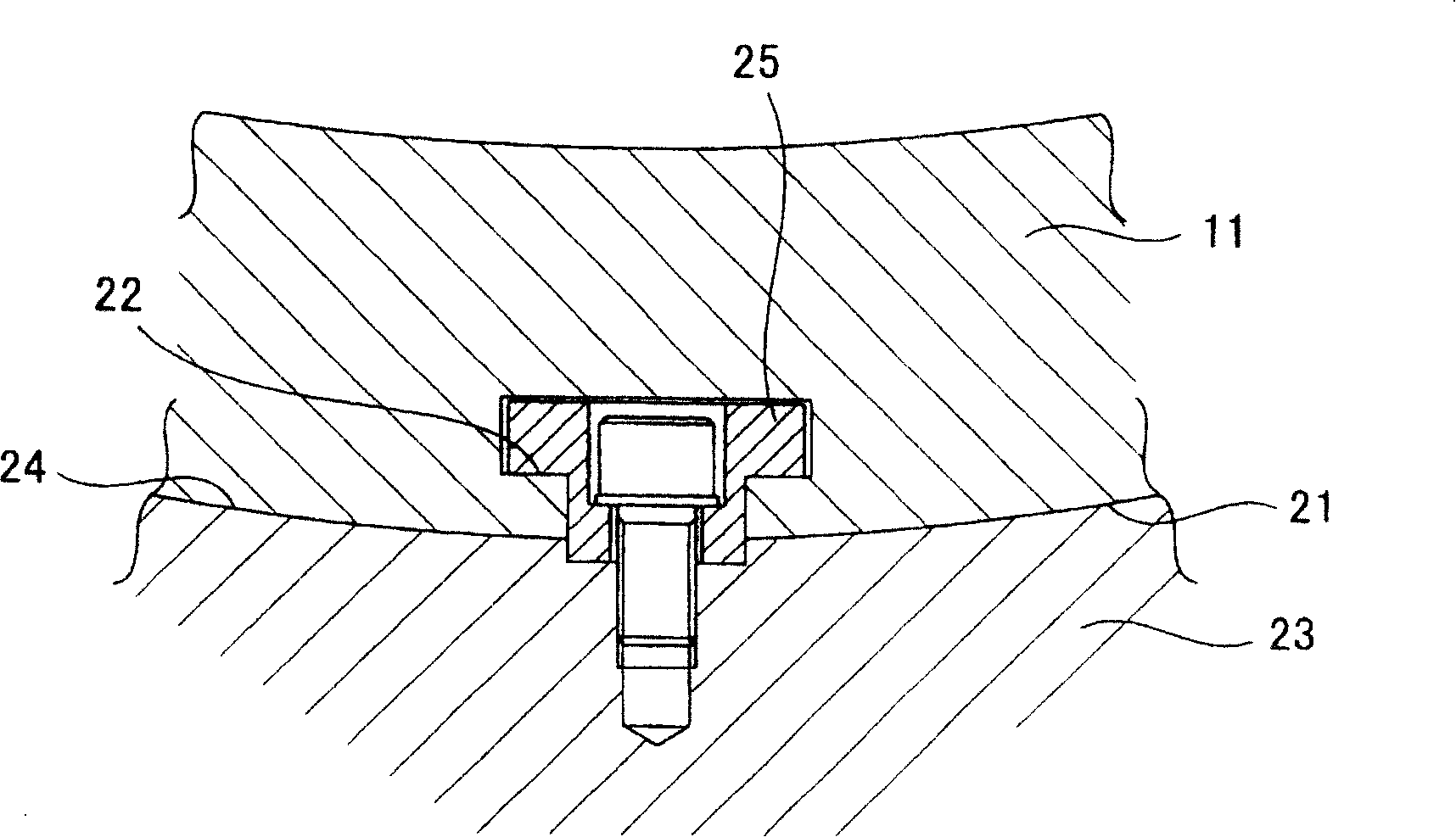

[0049] Next, the tire vulcanizer of the present invention will be described in detail based on examples. Fig. 1 is a partial sectional view of the tire vulcanizing device of the embodiment, the left side of the center line shows the state of locking the tread mold, and the right side of the center line shows the state of reaching the tread mold, figure 2 , image 3 It is the II-II arrow sectional view and III-III arrow sectional view in Fig. 1, Figure 4 is the plan view of the upper plate. Figure 5 , Figure 6 is a sectional view of the upper adjustment plate installed state, Figure 7 , Figure 8 It is a cross-sectional view of the installation state of the lower adjustment plate.

[0050] The main body of the tire vulcanizer includes a fixed base 1 on which a mold container 2 is formed. On the base 1 is fixed a lower pressure plate 3 which is an annular disc serving as a base of the mold container 2 . On the lower pressing plate 3 , an annular lower circular plate (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com