Jigsaw

A wire saw and core wire technology, applied in the direction of grinding machines, fine working devices, abrasives, etc., can solve the problems of reduced cutting speed, poor processing surface accuracy, and shortened life of wire saws, so as to maintain processing efficiency, Effect of preventing peeling of adhesive material and suppressing uneven wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, the present invention will be described based on the device embodiment.

[0046] First, the detection method and detection apparatus of the wire saw used for manufacturing the wire saw of this invention are demonstrated.

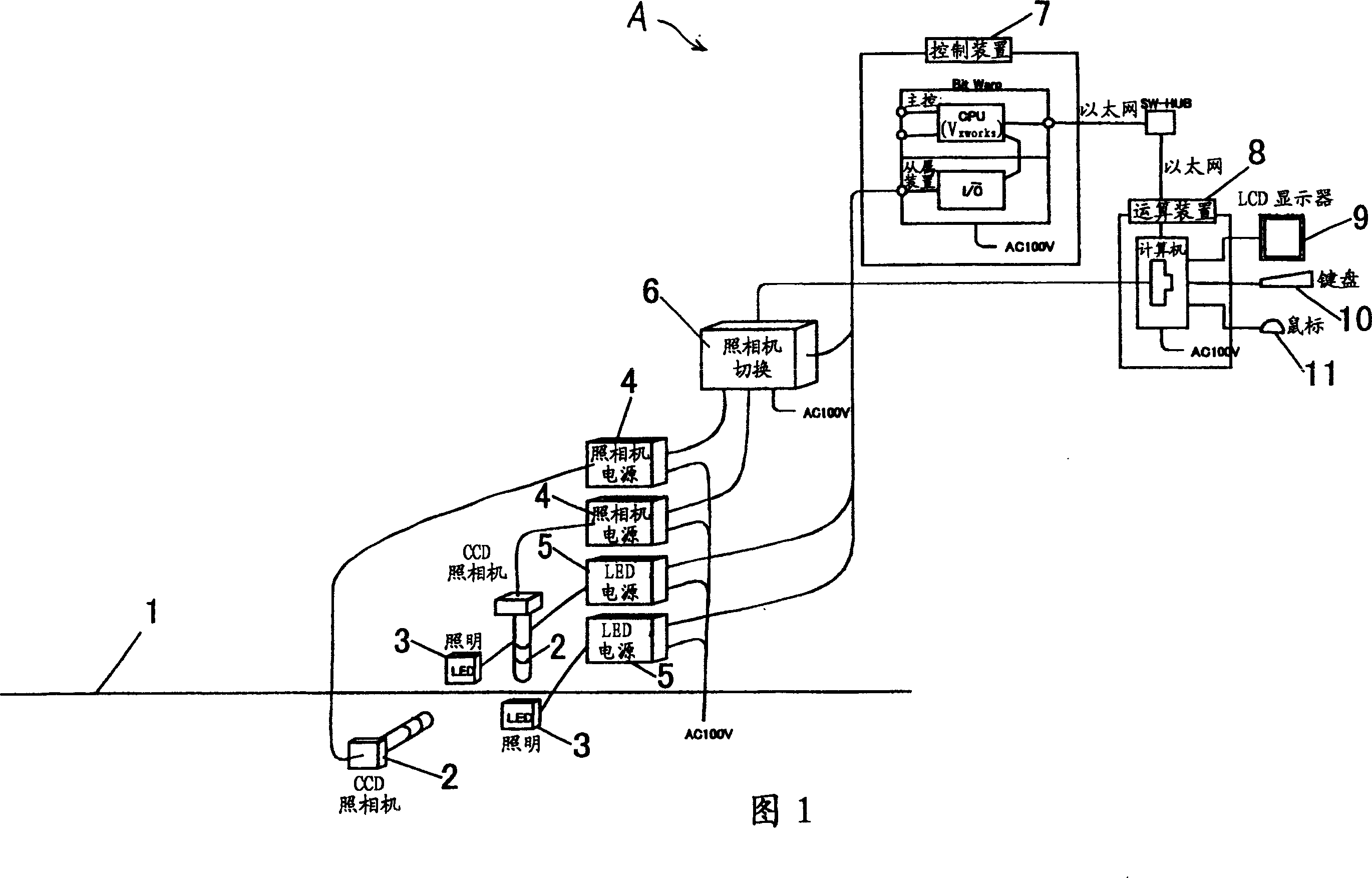

[0047] FIG. 1 shows a detection device A used in a detection process in the wire saw manufacturing process.

[0048]In FIG. 1 , a CCD camera 2 is arranged along two axial directions perpendicular to the longitudinal direction of the wire saw 1 and perpendicular to each other, and a CCD camera 2 is arranged opposite to the CCD camera 2 so as to sandwich the wire saw 1 . LED light source3. The CCD camera 2 is connected to a camera power supply 4 , and the LED light source 3 is connected to an LED light source power supply 5 . A camera switcher 6 is connected to the two camera power sources 4 , the camera switcher 6 and the two LED light sources 3 are connected to a control device 7 , and the control device 7 is connected to a computing de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com