Crawler belt

A track and track shoe technology, which is applied to tracked vehicles, motor vehicles, transportation and packaging, etc., can solve problems such as insufficient rigidity, and achieve the effect of firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

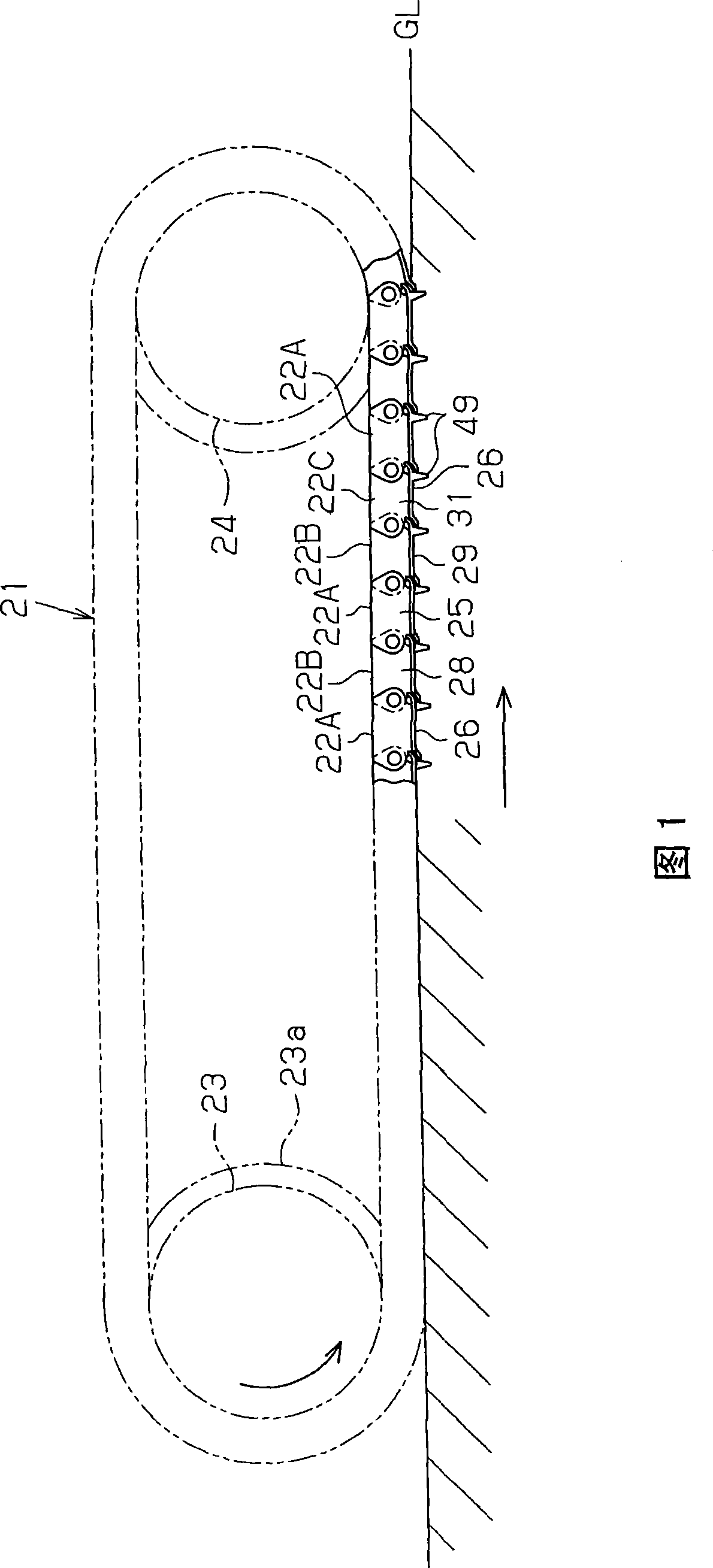

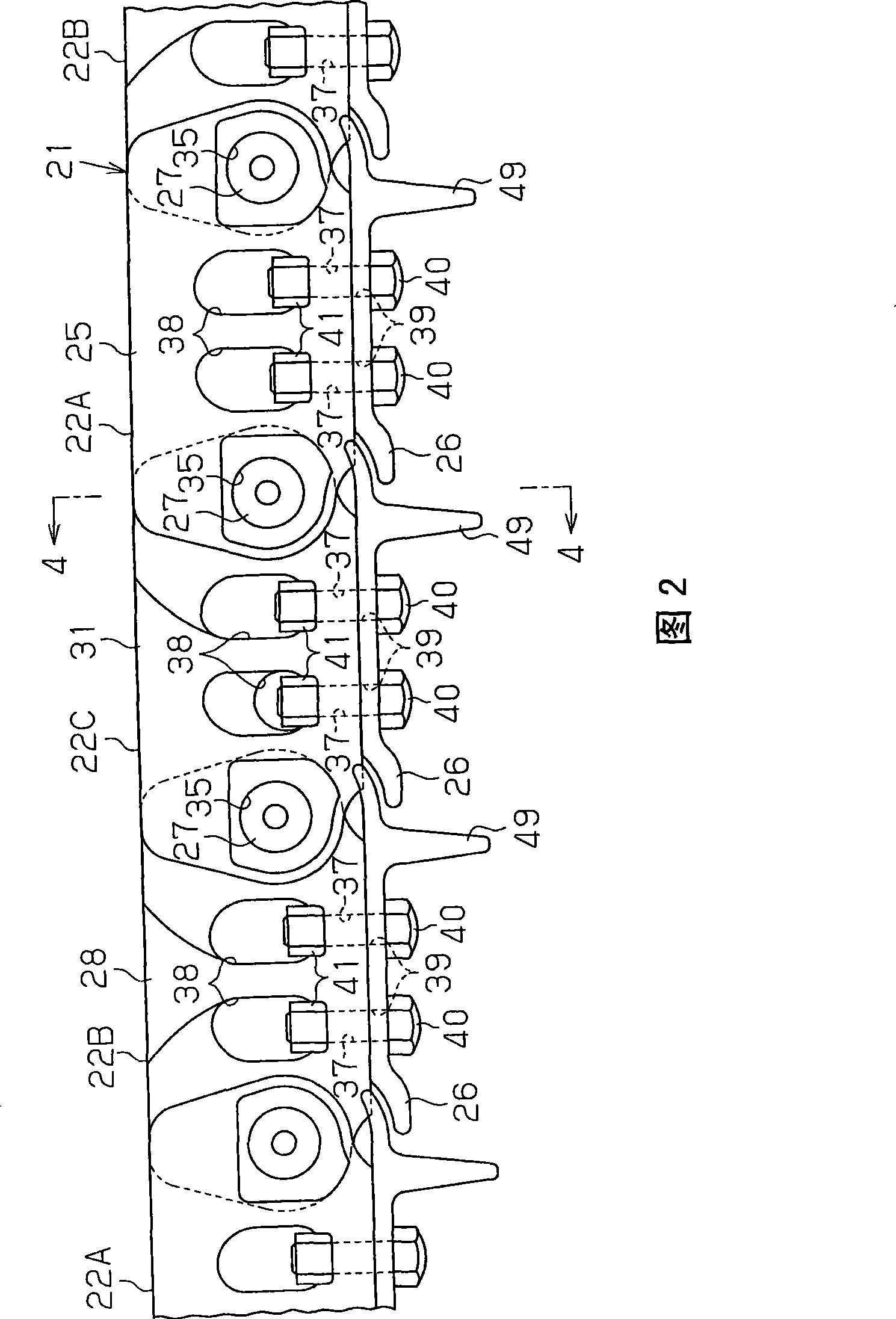

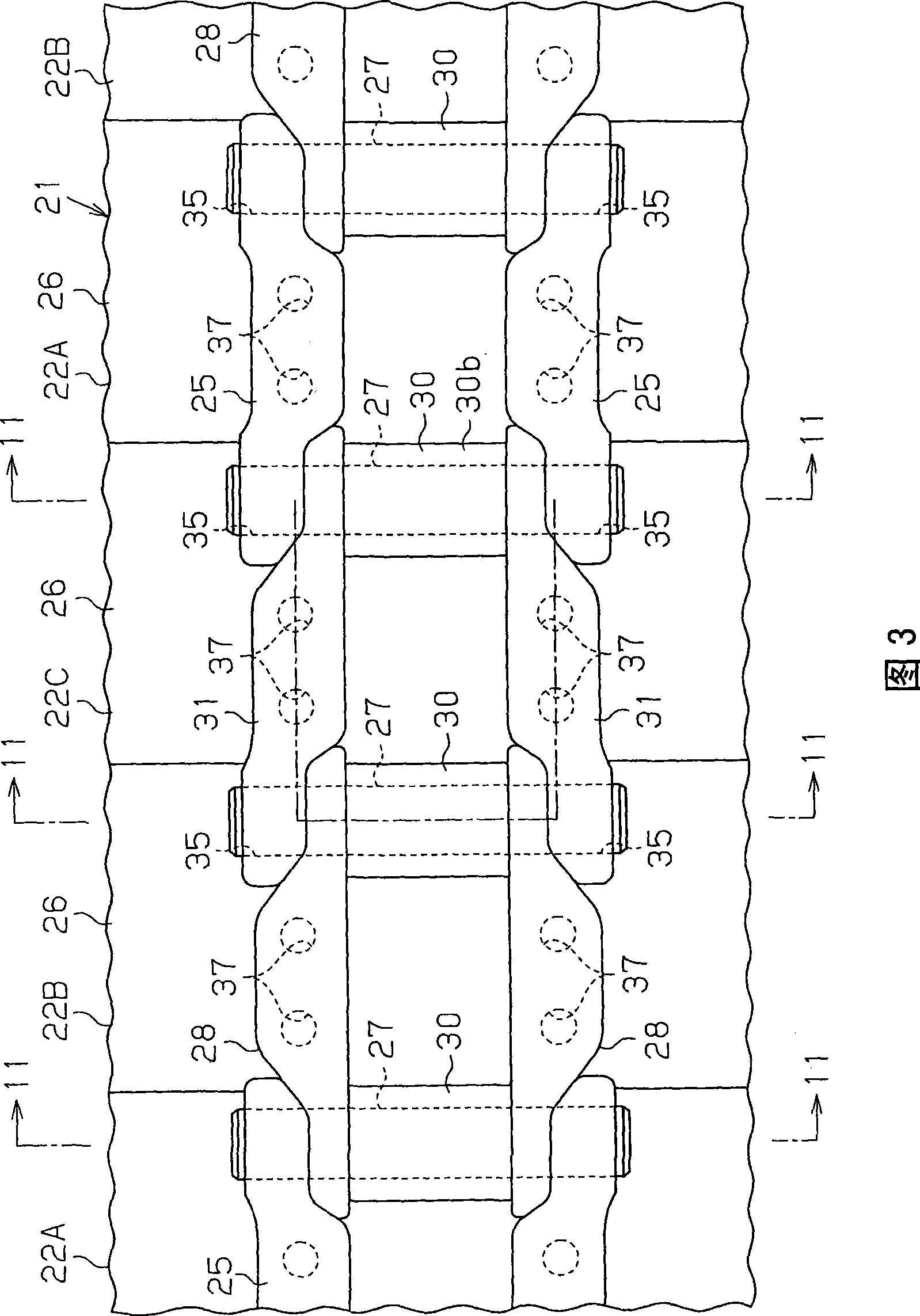

[0040] First, a first embodiment will be described with reference to FIGS. 1 to 12 . As shown in FIG. 1 , FIG. 2 , FIG. 3 and FIG. 12 , the crawler belt 21 of the first embodiment forms an endless structure by alternately arranging a plurality of first modules 22A and second modules 22B and connecting them. In this case, the first assembly 22A has support shafts 27 at both ends thereof, and the second assembly 22B has shaft sleeves 30 at both ends thereof. The first assembly 22A and the second assembly 22B are connected by fitting the bushing 30 on the support shaft 27 .

[0041] In this case, if any one of the first module 22A and the second module 22B is an odd number, the closed-loop crawler belt 21 cannot be formed. Therefore, when the total number of first and second modules 22A, 22B is an odd number, at least one (in this embodiment, one) third module is arranged and connected between the first module 22A and the second module 22B at any position. The assembly 22C enab...

no. 2 approach

[0065] Next, a second embodiment of the present invention will be described focusing on parts different from the first embodiment.

[0066] Figure 13 and Figure 14 As shown, in the second embodiment, a reinforcing plate 60 is provided as a reinforcing mechanism, and the reinforcing plate 60 is fixed to the lower surface of the track shoe 26 of the third link belt 31 by the bolt 40 fixing the third link belt 31 .

[0067] Therefore, in the second embodiment, the opening-side end portion of the third fastener tape 31 can be reinforced by the reinforcing plate 60 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com