Bacteriostatic bamboo charcoal fiber quilt clamping and airing equipment

A bamboo charcoal fiber and clamping technology, which is applied in the field of bamboo charcoal fiber, can solve the problems of long drying time and poor ventilation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

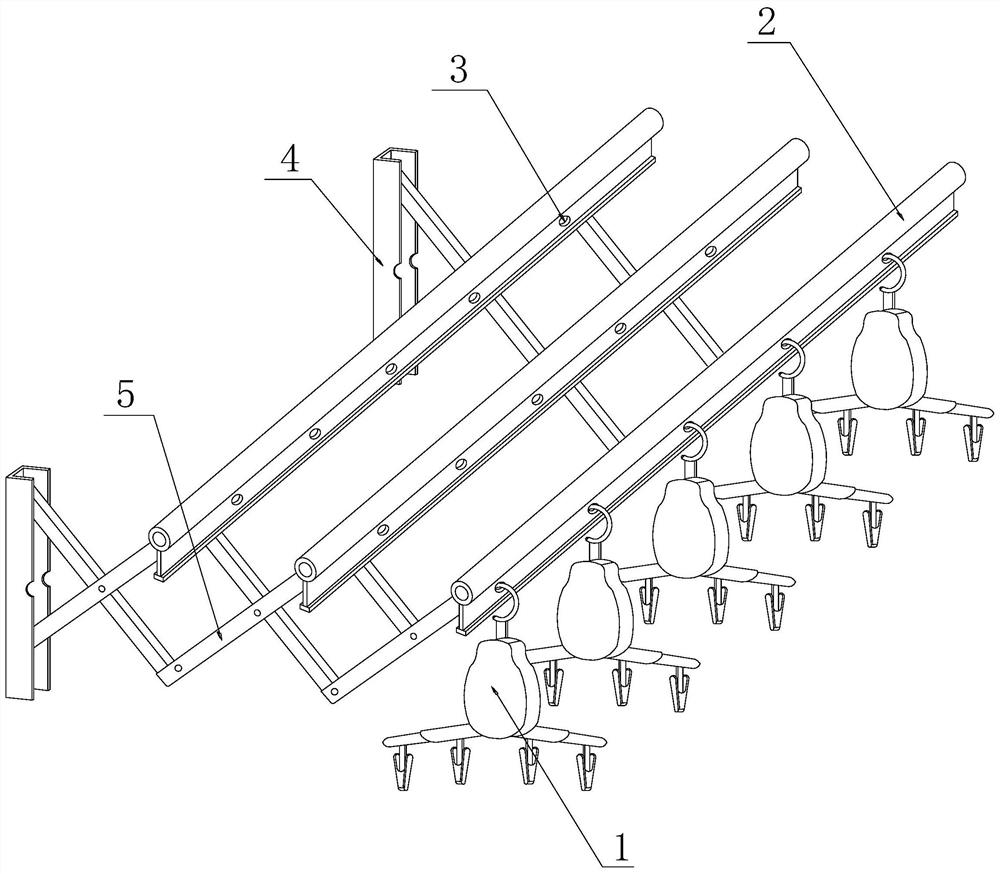

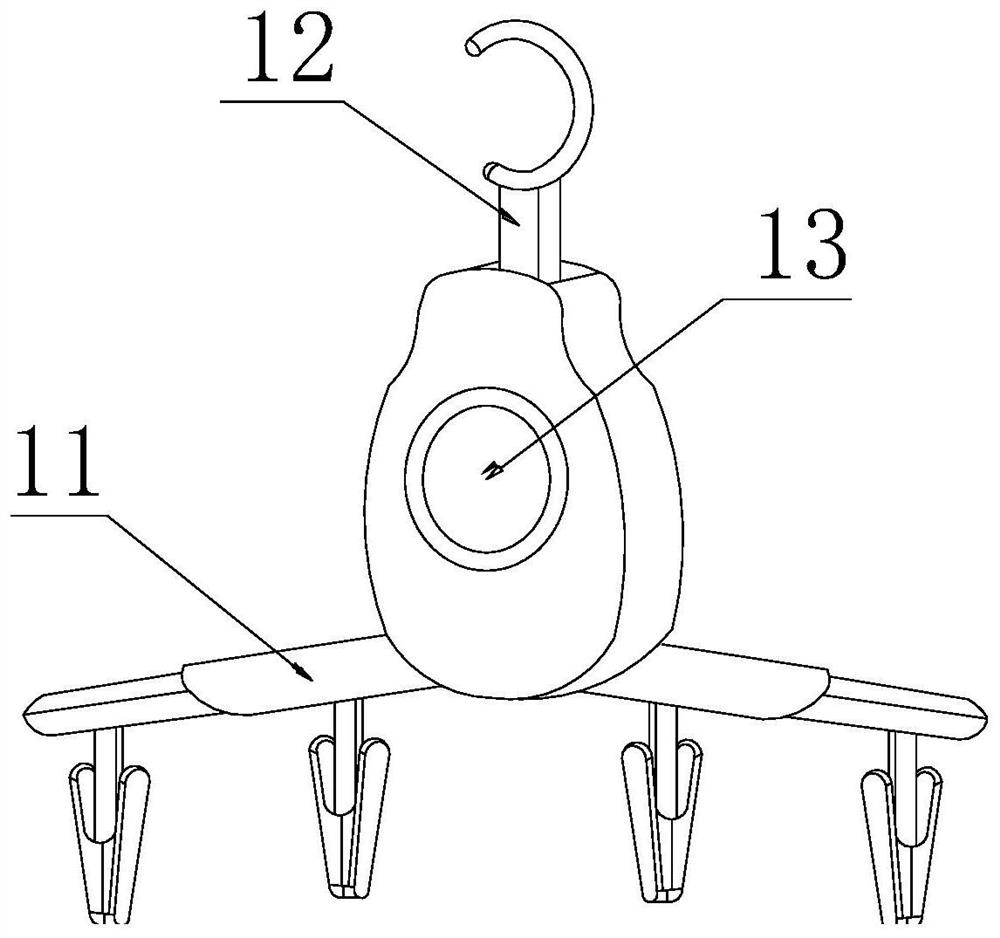

[0030] as attached figure 1 to attach Figure 5 Shown:

[0031] Its structure includes a quilt frame 1, a bearing rod 2, a fixing hole 3, a support seat 4, and a folding frame 5. The surface is embedded and connected, the left side of the bearing rod 2 is fixed to the surface of the folding frame 5 with bolts, the end of the folding frame 5 is fixed to the inner bolt of the support seat 4, and the clamp frame 1 includes an extension rod 11, a hook 12, and a counterweight Seat 13, the end of the extension rod 11 is nested with the inside of the counterweight seat 13, the top of the counterweight seat 13 is embedded and connected with the end of the hook 12, and the bottom of the hook 12 is in clearance fit with the two ends of the extension rod 11.

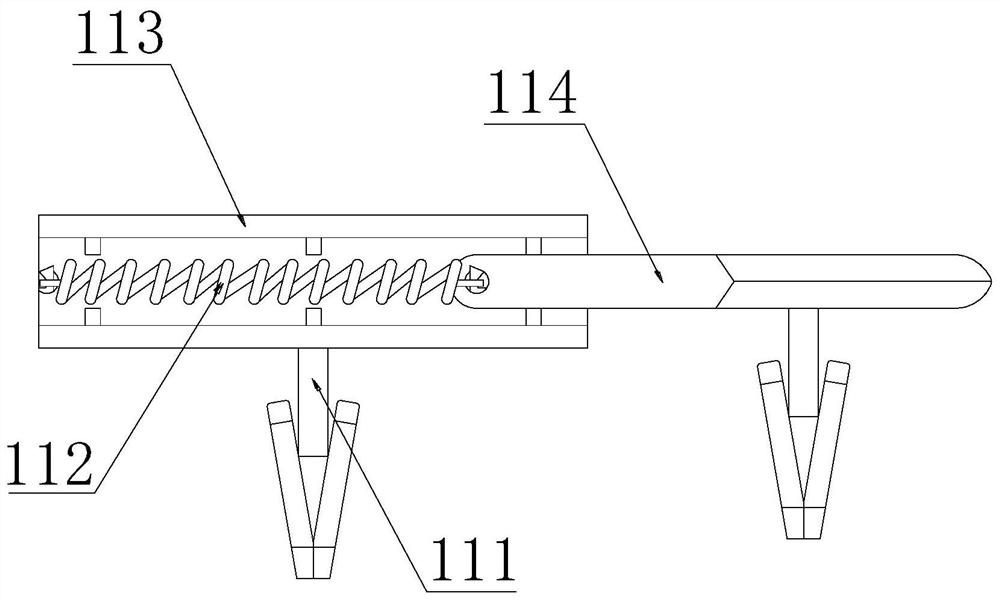

[0032] Wherein, the extension rod 11 includes a clamping head 111, a tension spring 112, a sleeve 113, and a sliding rod 114. The top end of the clamping head 111 is spirally connected with the outer surface of the sleeve 113, an...

Embodiment 2

[0038] as attached Figure 6 to attach Figure 9 Shown:

[0039] Wherein, the clamping rod a2 includes a collet a21, a fixing rod a22, a spring groove a23, and an inner groove a24. The chuck a21 is integrally embedded with the lower end of the fixing rod a22, and the inner surface of the fixing rod a22 is in contact with the inner concave The slot a24 is integrally embedded and connected, and the upper end of the inner groove a24 is in clearance fit with the lower end of the spring slot a23. The chuck a21 is distributed at the end of the fixed rod a22 and is embedded and connected with it. It has an integrated structure with the fixed rod a22. The groove a24 is beneficial to cooperate with the upper end structure for fixing, and to adjust the angle through fixing.

[0040] Wherein, the collet a21 includes a reinforcement block b1, a fixing bolt b2, and a rod body b3. The reinforcement block b1 is integrally embedded and connected to the inner side of the rod body b3. The sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com