Energy-saving and low-flow-resistance Y-type shutoff valve

A shut-off valve, low flow resistance technology, used in lift valves, valve devices, engine components, etc., can solve problems such as energy loss and eddy current generation, achieve reasonable structure and ensure the effect of matching streamlines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

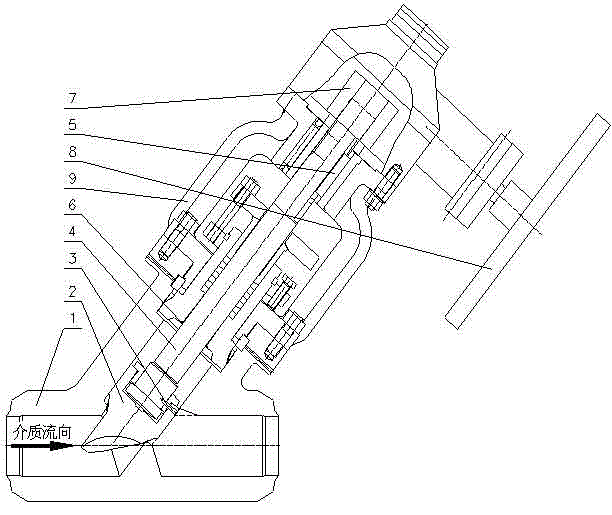

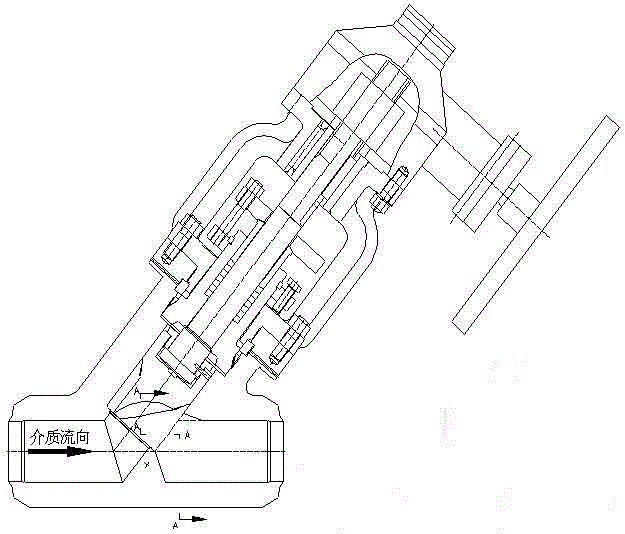

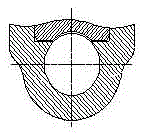

[0012] An energy-saving and low-flow-resistance Y-shaped globe valve, comprising a valve body 1, a valve disc 2, a valve disc positioning pin 3, a valve stem 4, a valve stem guide device 5, a valve cover upper seal 6, a valve stem nut 7, and a gear head Handwheel 8, bracket 9, etc., the end face of the valve disc is concave arc, and when the valve disc is fully open, the concave arc of the end face of the valve disc is in the form of an integral arc matching the flow channel where the end face of the valve disc is located.

[0013] The valve stem guide device is a valve stem guide key.

[0014] Operate the hand wheel 8 of the gear head to drive the valve stem nut 7 to rotate, and the valve stem 4 will produce a linear directional movement through the directional action of the key 5, and the valve disc positioning pin 3 will position the valve disc 2 and the valve stem 4, because the bracket 9 and the valve body 1 is a fixed connection, so the movement of the valve disc 2 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com