Preparation method of composite modified lithium metal soft package battery

A soft-pack battery and composite modification technology, which is applied in the manufacture of lithium batteries, electrolyte batteries, and battery electrodes, can solve problems such as complex chemical synthesis processes, chemical instability of lithium metal negative electrodes, and harsh environmental conditions, and achieve low control requirements , The modification method is simple and easy, and the effect of simple disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method for a composite modified lithium metal pouch battery, comprising the steps of:

[0040] 1) Making the positive electrode sheet: Disperse 67.06g of high-nickel ternary positive electrode material, 2g of superconducting carbon black, and 0.84g of PVDF in 39.2g of N-methylpyrrolidone, stir evenly, and coat on the positive electrode aluminum foil current collector. After drying at ℃, roll into sheets and cut; weld the cut positive electrode sheet and aluminum lug together, and fix it with insulating tape;

[0041] 2) Bake the positive electrode sheet: Put the obtained positive electrode sheet in a vacuum oven to dry, bake at 90°C for 24 hours, and continue vacuuming to control the moisture content of the positive electrode sheet to ≤200ppm;

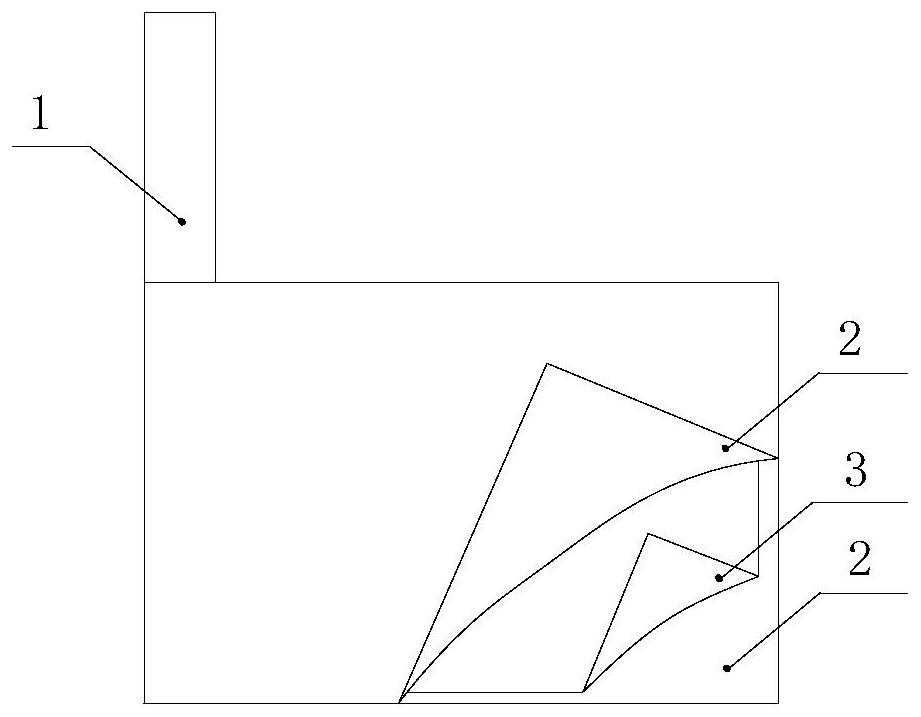

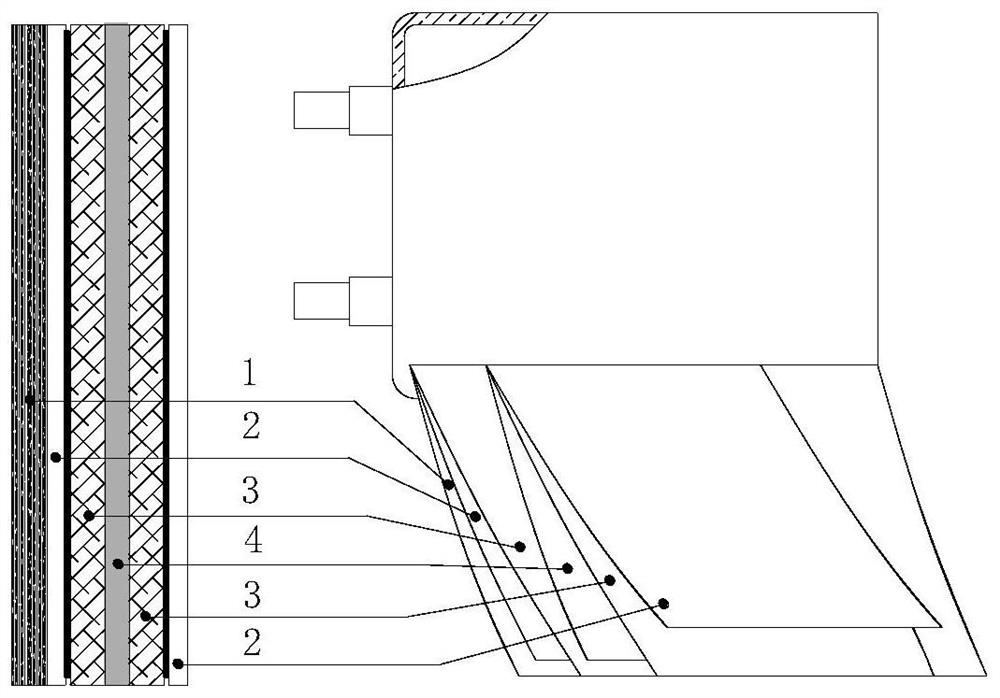

[0042] 3) To make the negative electrode sheet: spread the microporous copper foil with a pore size of 25 μm and a thickness of 9 μm on both sides of the lithium strip, and weld the nickel tab to one end of the mic...

Embodiment 2

[0053] A preparation method for a composite modified lithium metal pouch battery, comprising the steps of:

[0054] 1) Making the positive electrode sheet: Disperse 80g of high-nickel ternary positive electrode material, 2g of superconducting carbon black, and 2g of PVDF in 42g of N-methylpyrrolidone, stir evenly, and coat it on the positive electrode aluminum foil current collector, and dry it at 80°C , rolled into sheets, and cut; weld the cut positive electrode sheet and aluminum lug together, and fix it with insulating tape;

[0055] 2) Bake the positive electrode sheet: Put the obtained positive electrode sheet in a vacuum oven to dry, bake at 90°C for 24 hours, and continue vacuuming to control the moisture content of the positive electrode sheet to ≤200ppm;

[0056] 3) To make the negative electrode sheet: spread the microporous copper foil with a pore size of 10 μm and a thickness of 5 μm on both sides of the lithium strip, and weld the nickel tab to one end of the mic...

Embodiment 3

[0062] On the basis of Example 1, the carbon-coated separator is a PET film coated with nanoscale carbon powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com