Method and mold for preparing heat-conducting gasket and obtained heat-conducting gasket

A technology of thermally conductive gaskets and molds, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of complexity, efficiency and cost that do not meet production needs, and consume large amounts of energy. The method is simple, the orientation is improved, and the The effect of reducing the number of processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0081] In order to use the mold to prepare a thermal pad, the application provides a method for using a similar mold, including the following steps:

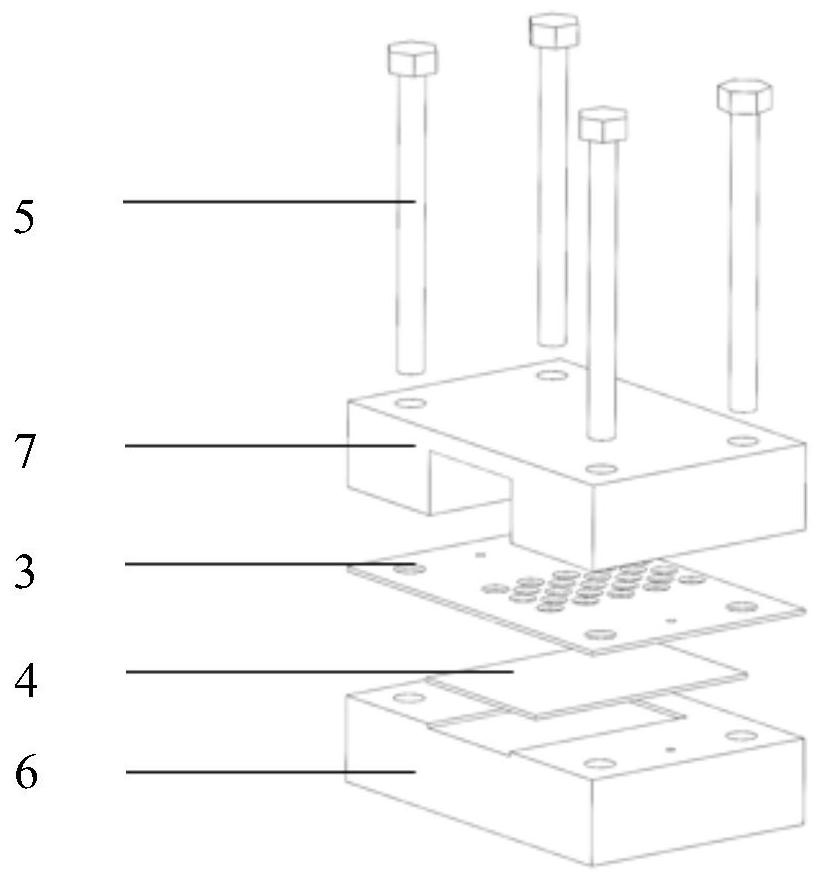

[0082] (1) Install the polymer storage bin 7, the metal partition plate 3, the metal mesh sheet 4 and the heat-conducting filler forming bin 6 in sequence, and fix the four together with fastening screws 5;

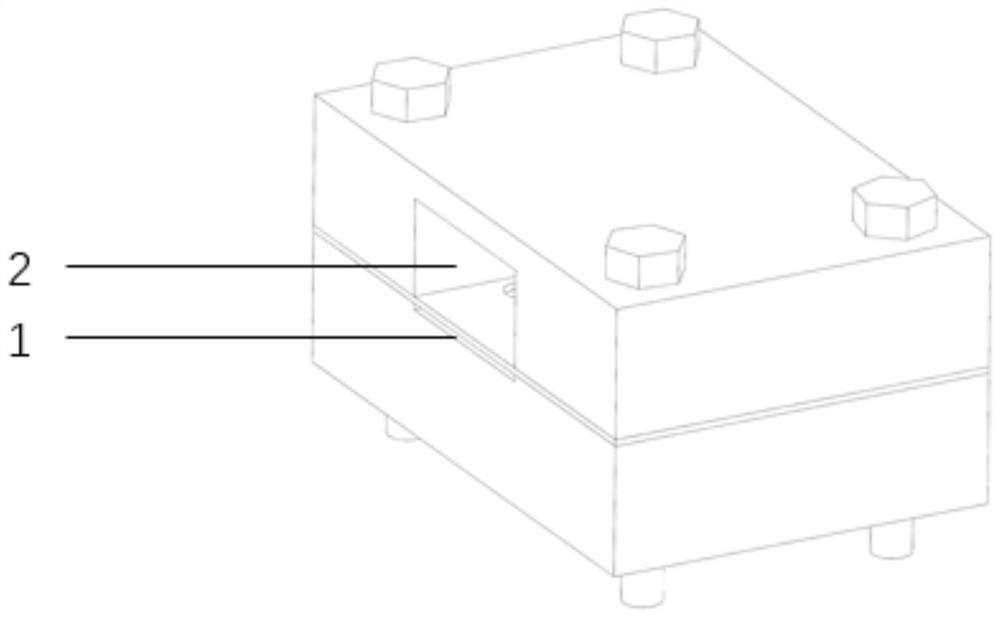

[0083] (2) Add the thermally conductive filler powder into the thermally conductive filler forming chamber 1 and shake it tightly, insert the metal pressing sheet into the groove a1 and press it tightly;

[0084] (3) Pour the liquid resin matrix precursor (ie high molecular polymer) into the groove b2.

[0085] (4) Put the mold into the vacuum chamber, use a vacuum pump to extract the air between the fillers, and the liquid resin matrix (ie polymer) will fill the vacuum between the thermally conductive fillers to form a thermal pad precursor.

[0086] (5) Put the mold in step 4 into a heating oven to cure the resin.

[00...

Embodiment 1

[0089] Raw materials: 2 g of silicone oil, 2 g of hydrogenated silicone oil, 0.05 g of platinum catalyst, and 2 g of carbon fiber (particle size: 250 μm).

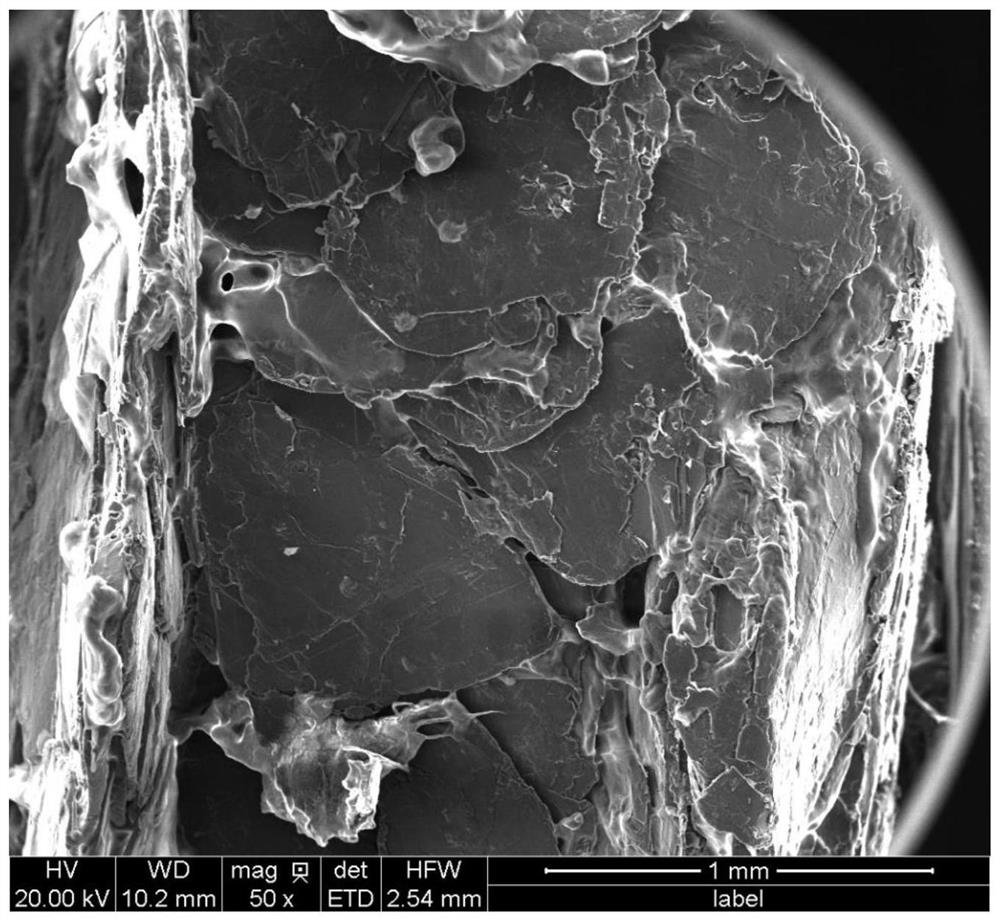

[0090] first as figure 1 Mount the mold as shown, pass the carbon fiber 2g through figure 2 The hatch of the shown thermally conductive filler layer forming bin 6 is filled. When filling, the vibration and compaction operations should be carried out at the same time, so that the carbon fiber heat-conducting filler added to each layer can be oriented and compacted in time. Then insert the metal press and compact. Then mix 2g of silicone oil, 2g of hydrogenated silicone oil, and 0.05g of platinum catalyst (silicone oil and hydrogenated silicone oil generate silicone rubber under the action of the catalyst), stir evenly, and pass through the figure 2 The hatch of the shown high molecular polymer storage bin 7 is filled. After filling, put the whole mold into the vacuum equipment, and use the vacuum pump to exhaust. At t...

Embodiment 2

[0092] Raw materials: 5 g of silicone oil, 5 g of hydrogenated silicone oil, 0.5 g of platinum catalyst, and 5 g of boron nitride (with a particle size of 10 μm). Ethyl acetate 1.5g.

[0093] first as figure 1 Install the mold and pass 5g of boron nitride through figure 2 The hatch of the shown thermally conductive filler layer forming bin 6 is filled. When filling, the operation of shaking and compacting should be carried out at the same time, so that the boron nitride thermal conductivity filler added in each layer can be oriented and compacted in time. Then insert the metal press and compact. Since boron nitride is a two-dimensional material, the filling is denser and the contact area is larger, and it is difficult for polymers to enter, so ethyl acetate needs to be added to dilute the resin. Then mix 5g of silicone oil, 5g of hydrogenated silicone oil, 0.5g of platinum catalyst, and 1.5g of ethyl acetate, stir evenly, and pass through the figure 2 The shown high mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com