Earth and rockfill dam for simulating piping dam break test

A technology of earth-rock dams and simulated pipes, applied in hydraulic models, etc., can solve problems such as the difficult pipe bursting process, the immature theory of cohesive soil and sediment migration, and the inapplicability of non-cohesive sand pipes, etc., to ensure integrity and avoid Effects that cannot be controlled and increase the success rate of the test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

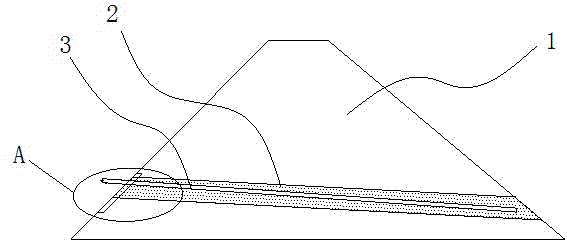

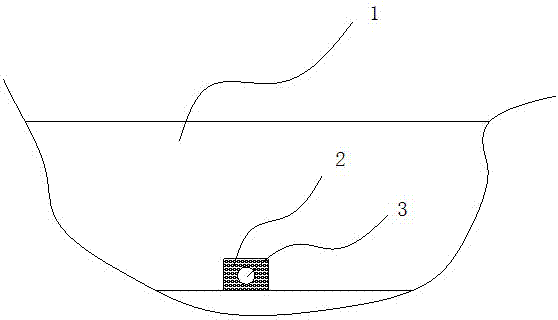

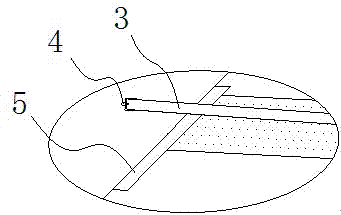

[0022] according to figure 1 , figure 2 and image 3 As shown, the present invention includes a dam body 1 . The dam body 1 is mainly formed by stacking earth and rock materials on the dam foundation, the elevation of the top of the dam body 1 is 8m, and the water level above the dam is 7.6m.

[0023] In the test plan, the position where the piping channel appears is preset at a height of 1m relative to the dam foundation. Therefore, a weak layer 2 mainly composed of sand is laid at a position 1m high from the dam foundation in the dam body 1 (of course, other materials that are easy to be lost under the scouring action of water flow can also be used for laying), and the depth of the weak layer 2 is 0.6 m, the width is 1.5m, and the sand is fine sand with a fineness modulus of 2.2-1.6.

[0024] In the weak layer 2, a water pipe 3 with a diameter of 30 cm is buried, and the water pipe 3 runs through the dam body 1 along the upstream and downstream directions of the dam bod...

Embodiment 2

[0030] according to figure 1 , figure 2 and image 3 As shown, the present invention includes a dam body 1 . The dam body 1 is mainly formed by stacking earth and rock materials on the dam foundation, the elevation of the top of the dam body 1 is 8m, and the water level above the dam is 7.6m.

[0031] In the test plan, the position where the piping channel appears is preset at a height of 1m relative to the dam foundation. Therefore, a weak layer 2 mainly composed of sand is laid at a position 1m high from the dam foundation in the dam body 1 (of course, other materials that are easy to be lost under the action of water flow can also be used for laying), and the depth of the weak layer 2 is 0.6m , the width is 1.5m, and the sand is fine sand with a fineness modulus of 2.2-1.6.

[0032] In the weak layer 2, a water pipe 3 with a diameter of 20 cm is embedded, and the water pipe 3 runs through the dam body 1 along the upstream and downstream directions of the dam body 1.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com