Nano-bubble generating device

A generating device and nano-bubble technology, which is applied in transportation and packaging, sustainable biological treatment, special treatment goals, etc., can solve the problems of small density of bubble distribution, complex structure design, and inability to quickly generate nano-bubbles, etc., to achieve enhanced stability performance, simple structural design, and the effect of extending the flow path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

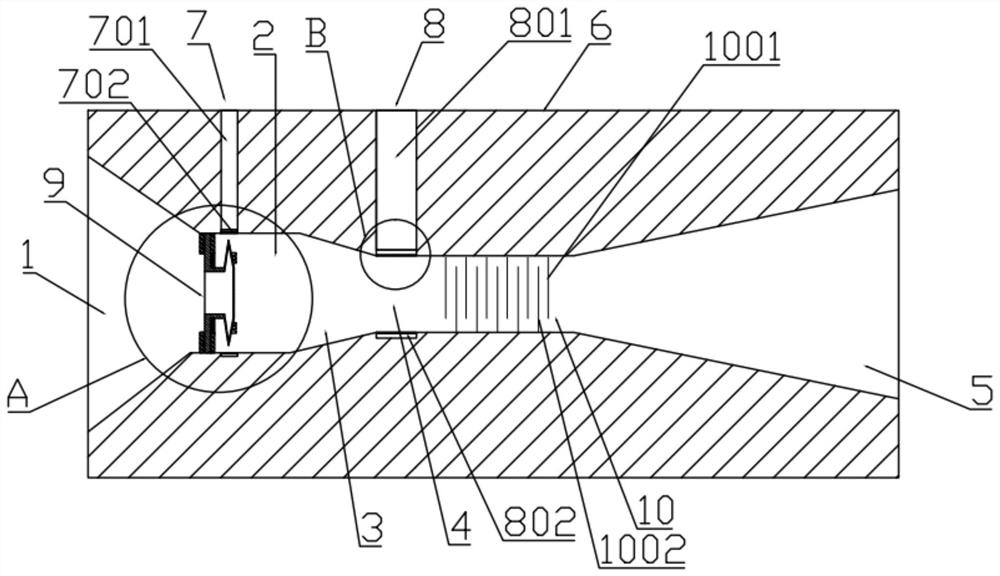

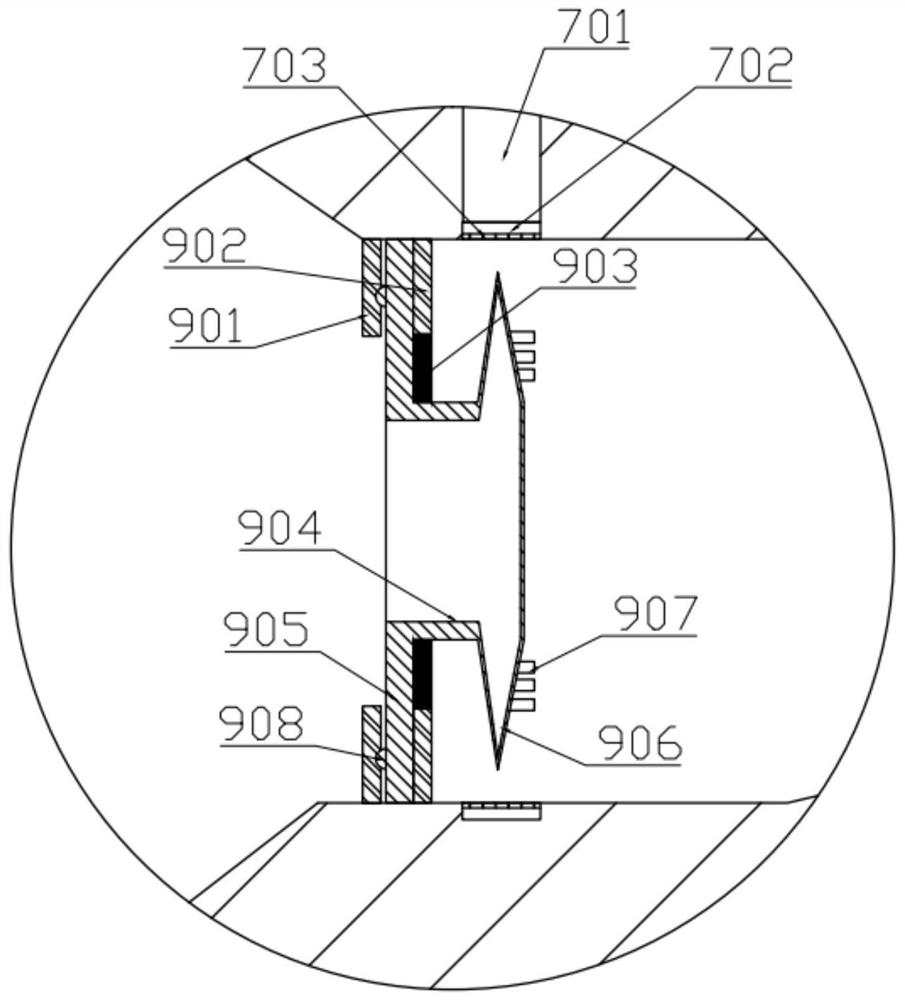

[0025] like Figure 1-5 In the shown embodiment, a nanobubble generating device includes a columnar body 6, and the columnar body 6 is sequentially provided with a first liquid through hole 1, a second liquid through hole 2, a third liquid through hole 3, and a fourth liquid through hole along the axial direction. The liquid through hole 4 and the fifth liquid through hole 5, the first liquid through hole 1 has a tapered structure from the beginning of the columnar body 6 to the second liquid through hole 2, and the second liquid through hole 2 has a cylindrical structure , the third liquid through hole 3 is a tapered structure tapered from the second liquid through hole 2 to the fourth liquid through hole 4, the fourth liquid through hole 4 is a columnar structure, and the fifth liquid through hole 5 is formed by the fourth liquid through hole The conical structure that the liquid through hole 4 reduces to the end of the columnar body 6; the columnar body 6 is provided with a...

Embodiment 2

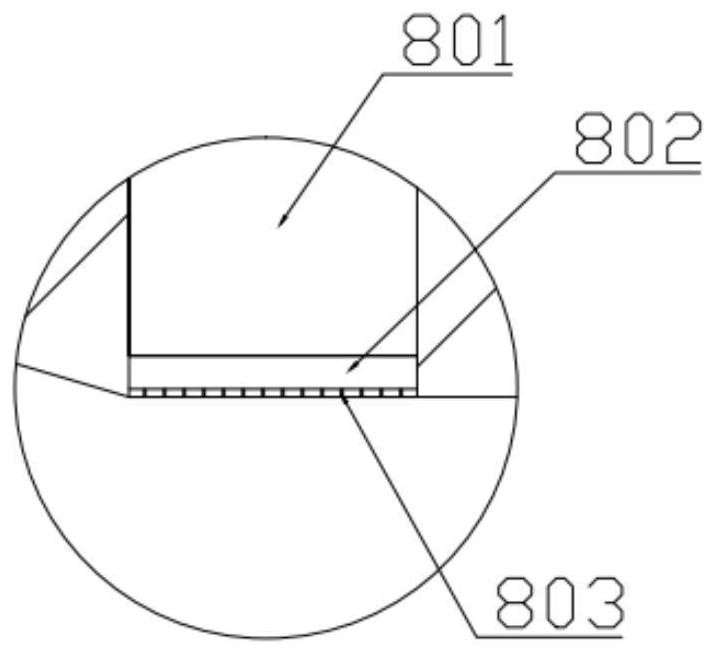

[0036] The structure of embodiment 2 is basically the same as that of embodiment 1, and its difference is: as Image 6 As shown, the first air intake chamber 701 communicates with the top of the second air intake chamber 801 , and the communicating part communicates with the outside air through the total air intake chamber inclined to the first air intake chamber 701 . According to the Venturi effect, since the diameter of the fourth liquid through hole 4 is smaller than the diameter of the second liquid through hole 2, most of the external air enters the fourth liquid through hole 4 along the second air intake chamber 701 after entering from the total air intake chamber. However, because the inner diameter of the first air intake chamber 701 is smaller than the inner diameter of the second air intake chamber 801, the pressure of the fluid in the first air intake chamber 701 is greater than the pressure of the second air intake chamber 801, and there is also a Venturi effect, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com