Filling material, equipment and method for bituminous pavement coring test hole

A technology of asphalt pavement and equipment, which is applied in the field of pavement engineering repair, can solve the problems of filling incompactness, etc., and achieve the effects of filling test holes, saving resources, and prolonging the durability of pavement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

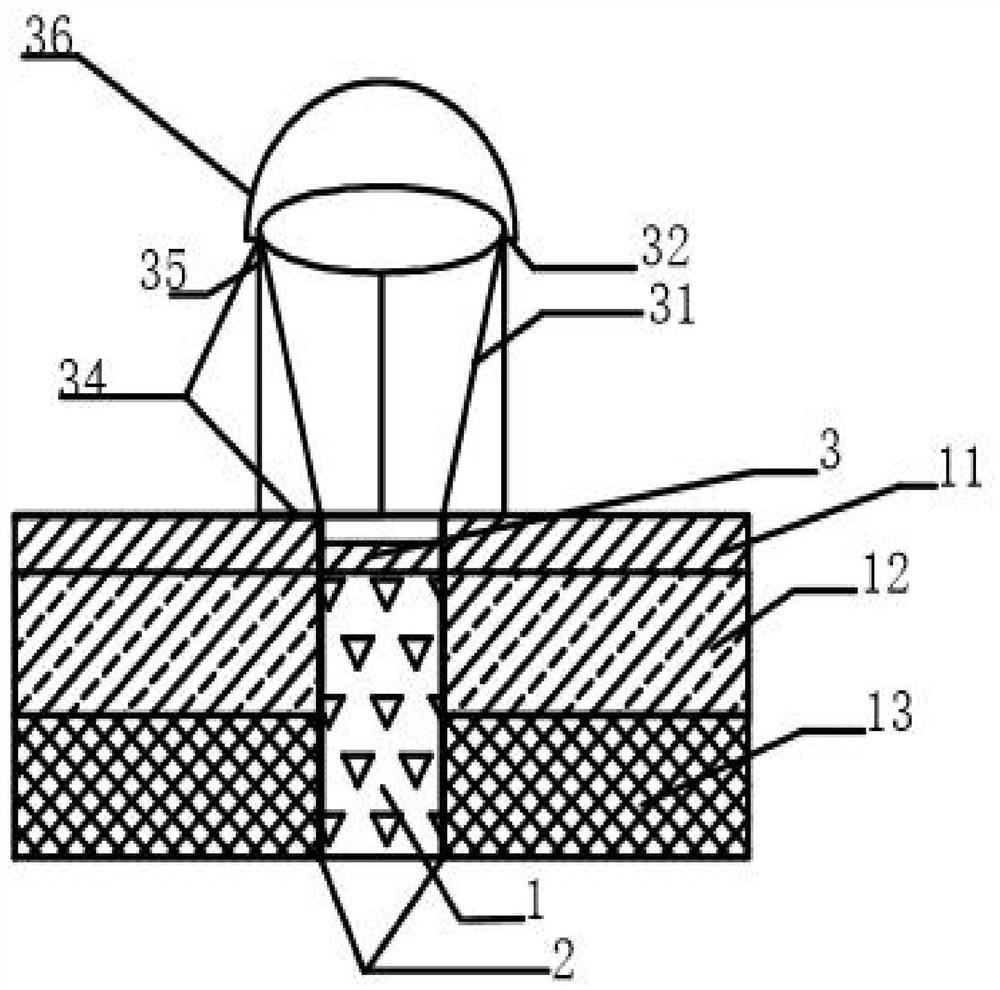

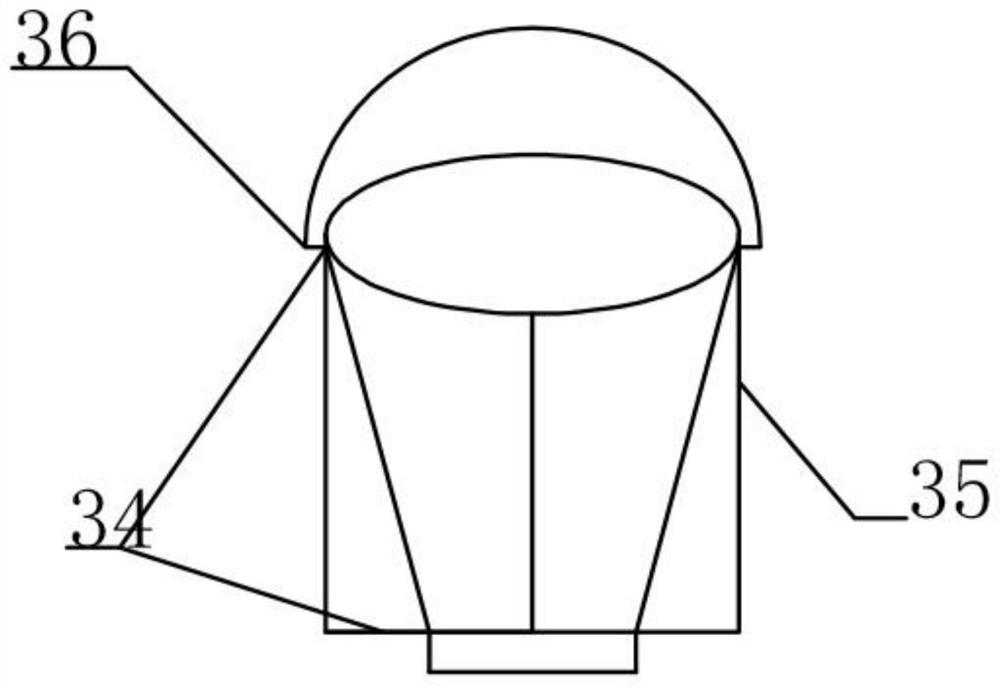

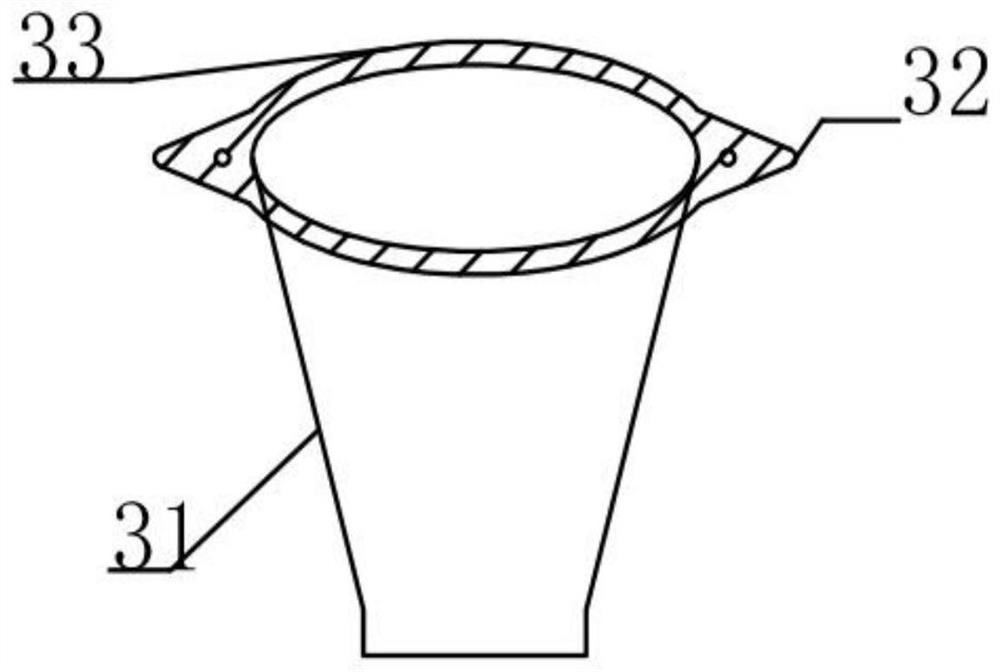

[0032] like Figure 1 to Figure 4 Shown, a kind of filling material, equipment and method for asphalt pavement coring test hole, including test hole filling material 1, funnel 31 and tamping rod 4, test hole filling material 1 is super toughness quick setting cement concrete, test hole Filling material 1 is made by mixing aggregates, yellow sand, cement, rubber particles, water, early strength agent and expansion agent in proportion. Ordinary Portland cement P.O42.5 or P.O32.5, the yellow sand is medium-coarse sand, the fineness modulus is 2.3-3.0 or 3.1-3.7, and the expansion agent is 80-85% of natural anhydrous gypsum, natural It is a combination of 10% alum stone and 5-10% calcined coal gangue. The bulking agent can moderately expand the cement concrete to reduce the volume shrinkage of the concrete, fully fill the gap between the asphalt concrete and the cement concrete, and achieve compactness and compactness. The role of water.

[0033] The test hole filling material 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com