Developing solution for photoresist

A technology of photoresist and developer, applied in optics, photography, liquid soap, etc., can solve unsatisfactory problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10 and comparative example 1~3

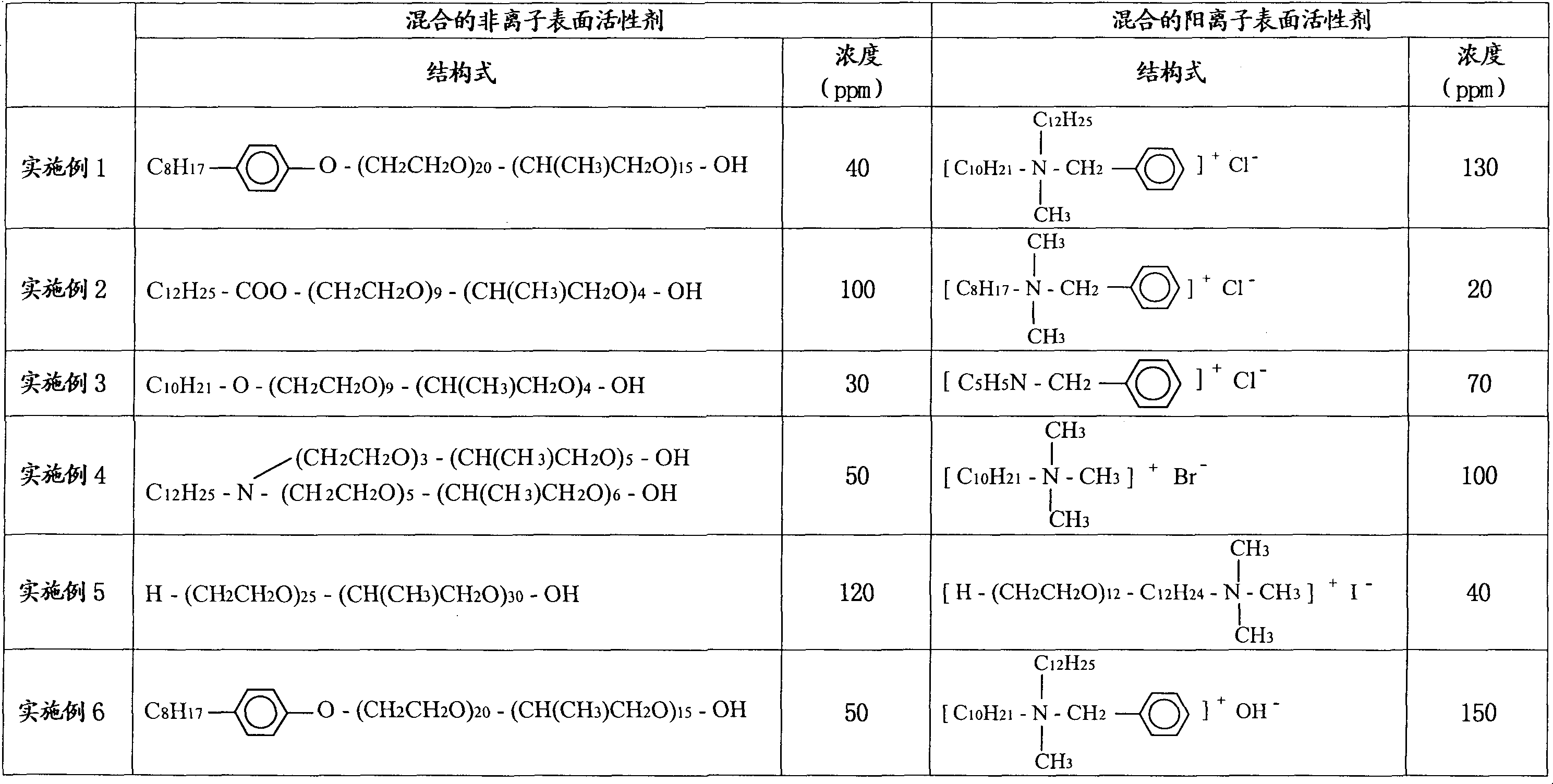

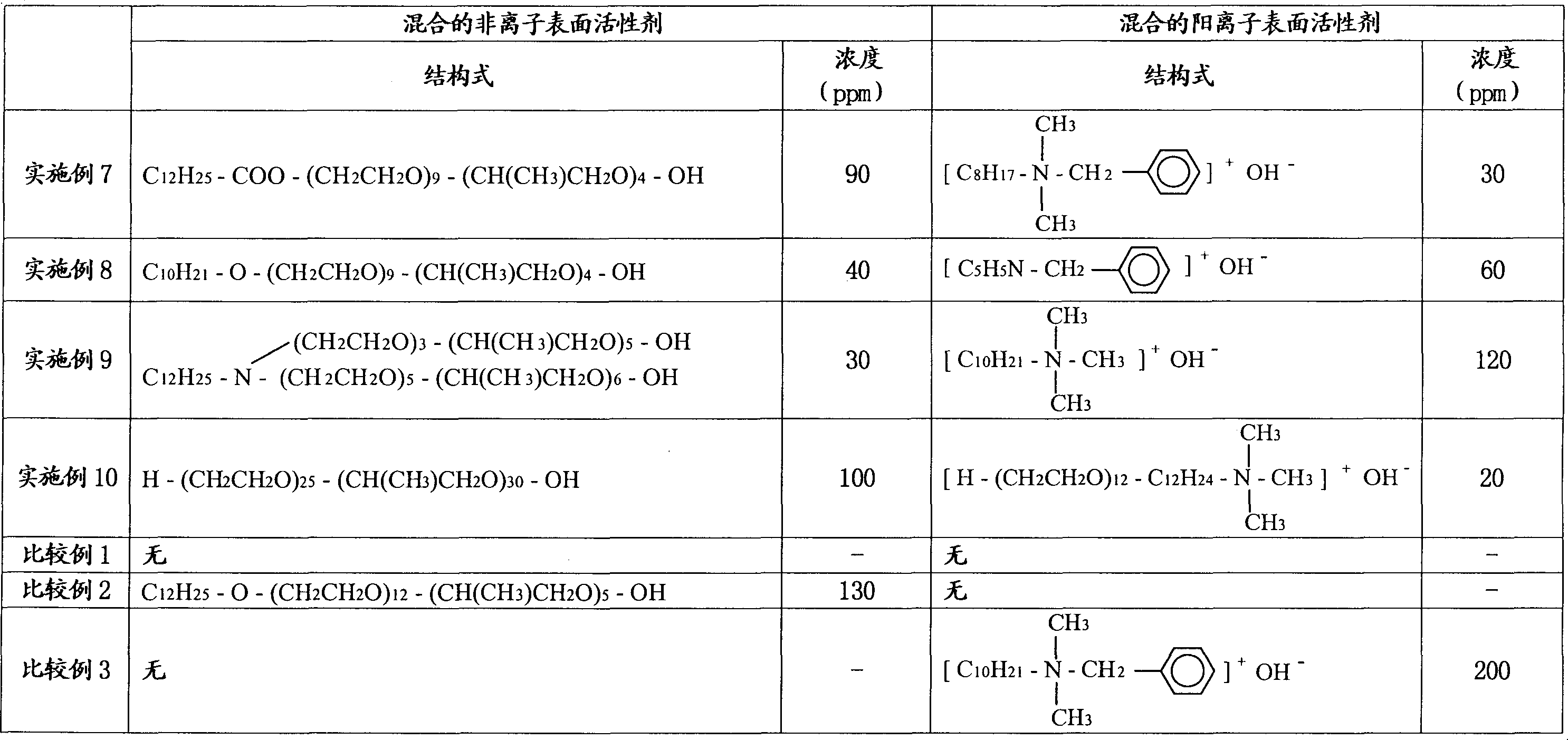

[0059] As a developing solution, the surfactant and the amount shown in Table 1 were added to a 2.38% by weight aqueous solution of TMAH (trade name SD-1 manufactured by Tokuyama Co., Ltd.). The surface tension was determined for the adjusted developer solution. The results are shown in Table 2.

[0060] Next, a silicon wafer was prepared, and the treated surface was cleaned with sulfuric acid-hydrogen peroxide (volume ratio 4:1). Then, baking was performed on a hot plate at 200° C. for 60 seconds. After baking, apply hexamethyldisilazane (HMDS) to hydrophobize the wafer surface. Next, chemically amplified positive photoresists A (t-Boc type), B (acetal type), and C (ESCAP type) for KrF excimer lasers were coated on the silicon wafer with a spin coater. Finally, prebaking was carried out under the conditions shown in Table 3, cooling after prebaking, and then exposing for 100 seconds with an ultraviolet lamp (7 μW) having a spectrum of 248 nm in a square range of 12×12 mm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com