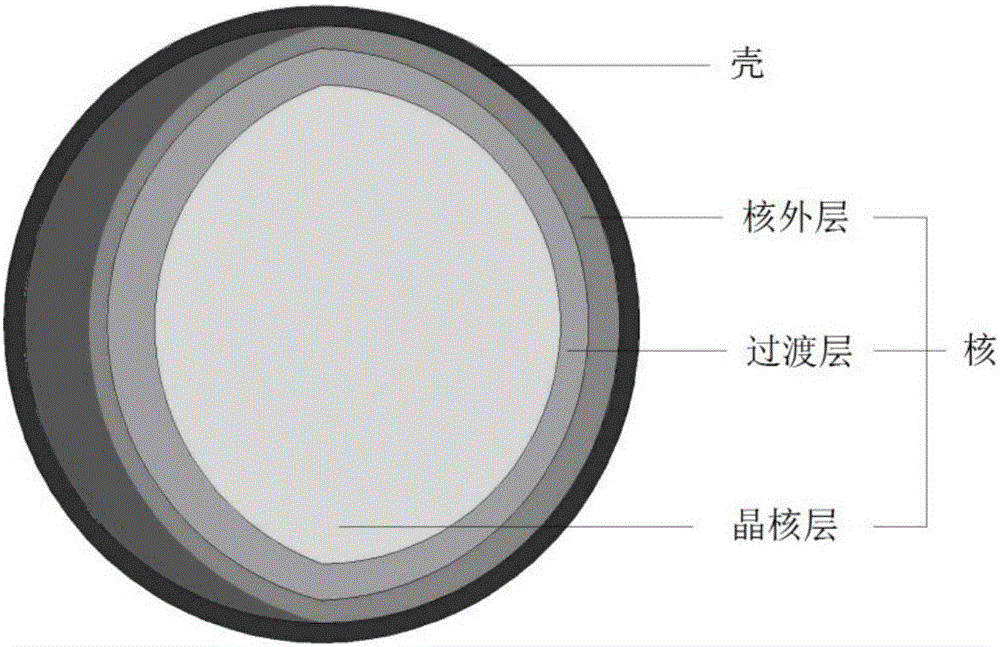

Modified sialon fluorescence powder particle and preparation method thereof as well as sialon fluorophor and luminescent devices

A phosphor particle and modification technology, applied in semiconductor devices, luminescent materials, chemical instruments and methods, etc., can solve the problems of inability to prove anti-aging performance, affect the stability of phosphor powder, and be unsuitable for industrialization, and achieve a crystal structure. Solid and stable, good anti-aging and light decay performance, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

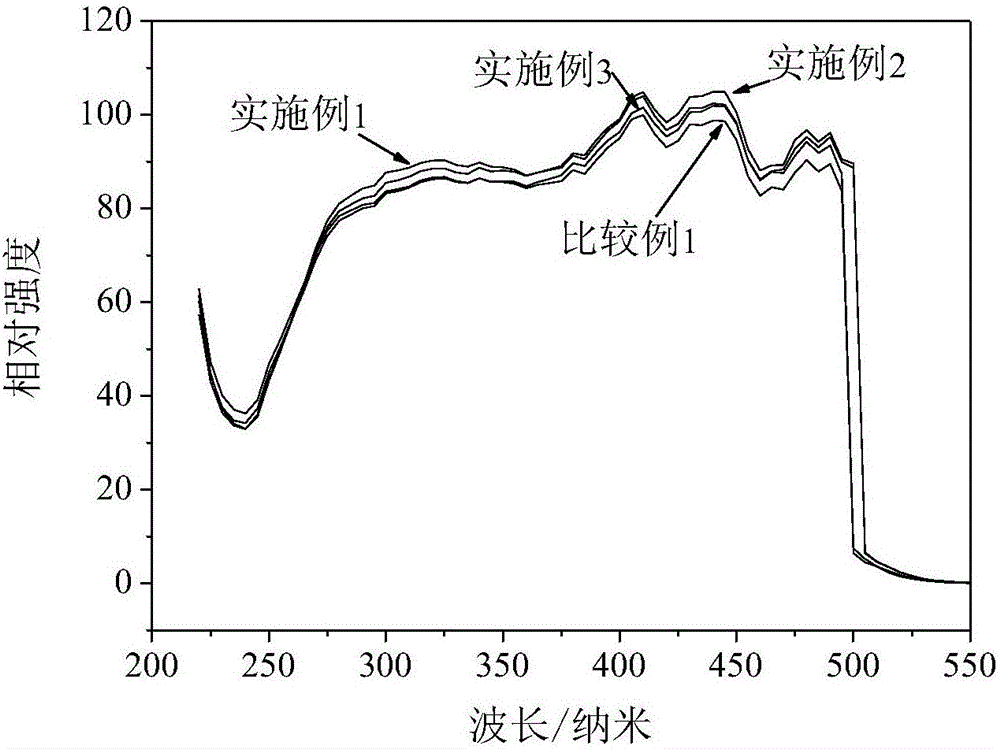

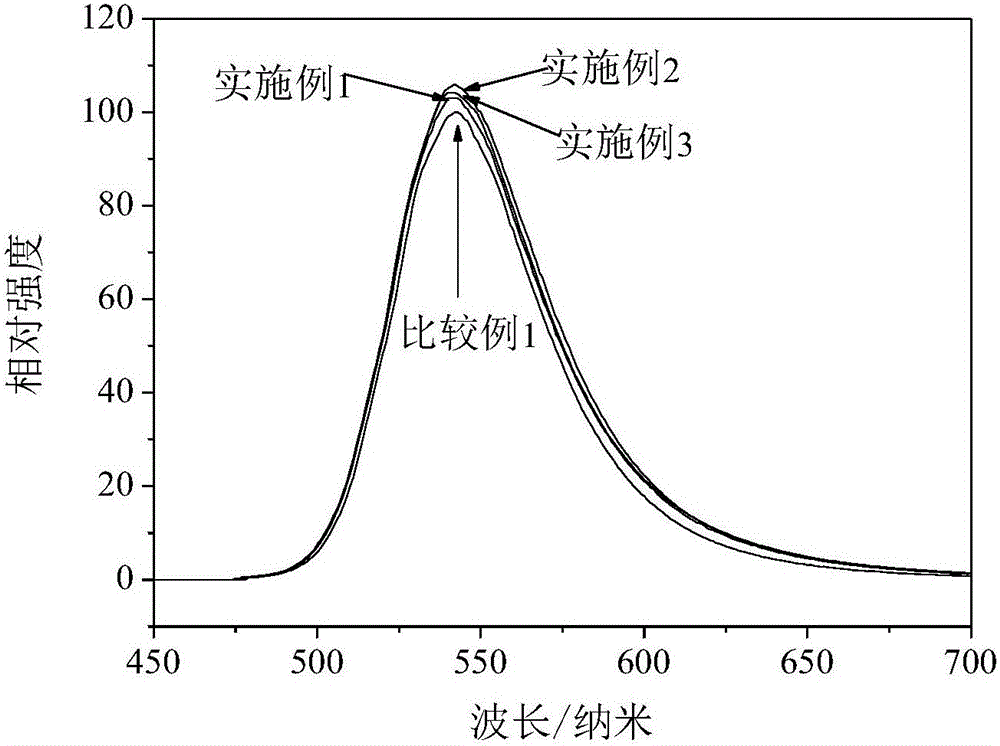

Embodiment 1

[0047] Weigh Si 3 N 4 19.366g, AlN0.522g, Eu 2 o 3 0.112g, mix the above raw materials in a nitrogen atmosphere for 1 hour to form a nuclear mixture, put it into a BN crucible, then quickly move it into a carbon tube furnace, then gradually raise the temperature to 1850°C under the protection of a nitrogen atmosphere, and keep it warm for 8 hours , the atmosphere pressure is 5Mpa, and then the temperature is lowered to 350°C, and the air is introduced at a speed of 5L / min for roasting, and the roasting time is 3h to form a semi-finished product with a nucleus; weigh Si 3 N 4 19.199g, AlN0.801g, the above raw materials are fully mixed in a nitrogen atmosphere for 1h to form a shell mixture, put it into a BN crucible, then quickly move it into a carbon tube furnace, and then gradually raise the temperature to 1600 under the protection of a nitrogen atmosphere ℃, keep warm for 6 hours, and the atmosphere pressure is 2Mpa to form a semi-finished shell. The semi-finished shell ...

Embodiment 2

[0049] Weigh Si 3 N 4 19.32g, AlN0.565g, EuF 3 0.115g, mix the above raw materials in a nitrogen atmosphere for 1 hour to form a nuclear mixture, put it into a BN crucible, then quickly move it into a carbon tube furnace, then gradually raise the temperature to 1850°C under the protection of a nitrogen atmosphere, and keep it warm for 8 hours , the atmosphere pressure is 5Mpa, and then the temperature is lowered to 350°C, and the air is introduced at a speed of 5L / min for roasting, and the roasting time is 3h to form a semi-finished product with a nucleus; weigh Si 3 N 4 19.686g, AlN0.314g, the above raw materials were fully mixed in nitrogen atmosphere for 1h to form a shell mixture, put it into a BN crucible, then quickly moved it into a carbon tube furnace, and then gradually raised the temperature to 1600 under the protection of nitrogen atmosphere ℃, keep warm for 6 hours, and the atmosphere pressure is 2Mpa to form a semi-finished shell. The semi-finished shell is cru...

Embodiment 3

[0051] Weigh Si 3 N 4 19.491g, AlN0.358g, EuCl 30.151g, mix the above raw materials in a nitrogen atmosphere for 1 hour to form a nuclear mixture, put it into a BN crucible, then quickly move it into a carbon tube furnace, then gradually raise the temperature to 1850°C under the protection of a nitrogen atmosphere, and keep it warm for 8 hours , the atmosphere pressure is 5Mpa, and then the temperature is lowered to 350°C, and the air is introduced at a speed of 5L / min for roasting, and the roasting time is 3h to form a semi-finished product with a nucleus; weigh Si 3 N 4 19.16g, AlN0.84g, the above raw materials are fully mixed in nitrogen atmosphere for 1h to form a shell mixture, put it into a BN crucible, then quickly move it into a carbon tube furnace, and then gradually raise the temperature to 1600 under the protection of nitrogen atmosphere ℃, keep warm for 6 hours, and the atmosphere pressure is 2Mpa to form a semi-finished shell. The semi-finished shell is crushed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com