Nitrogenous light-emitting particle, nitrogenous light-emitting particle preparation method, nitrogenous light emitter and light emitting device

A technology of luminescent particles and luminescent crystals, which is applied to optical elements, semiconductor devices, and luminescent materials used to change the spectral characteristics of emitted light, and can solve the problem of decreased luminous intensity of phosphor powder, low luminous efficiency of phosphor powder, and weak energy conversion efficiency. Low-level problems, to achieve solid and stable crystal structure, good anti-aging and light-fading properties, and excellent anti-aging and light-fading effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] A preparation method 1 of a nitrogen-containing luminescent particle and its preferred solution proposed by the present invention includes the following specific steps:

[0052] Step 1: Use the nitrides, oxides or halides of M, A, B, R as raw materials, according to the general chemical formula M m-m1 A a1 B b1 o O1 N n1 :R m1 The stoichiometric ratio of the cations in the composition weighs the required raw materials;

[0053] Step 2: mixing the raw materials weighed in step 1 uniformly in a nitrogen atmosphere to form a mixture;

[0054] Step 3: Roast the mixture obtained in step 2 at a high temperature in a roasting atmosphere, then cool down to a predetermined temperature, and then pass in nitrogen-oxygen mixed gas or air for low-temperature roasting to obtain a semi-finished product of nitrogen-containing luminescent particles;

[0055] Wherein: the high-temperature calcination temperature is 1400-2000°C, and the high-temperature calcination time is 6-18h; th...

Embodiment 1

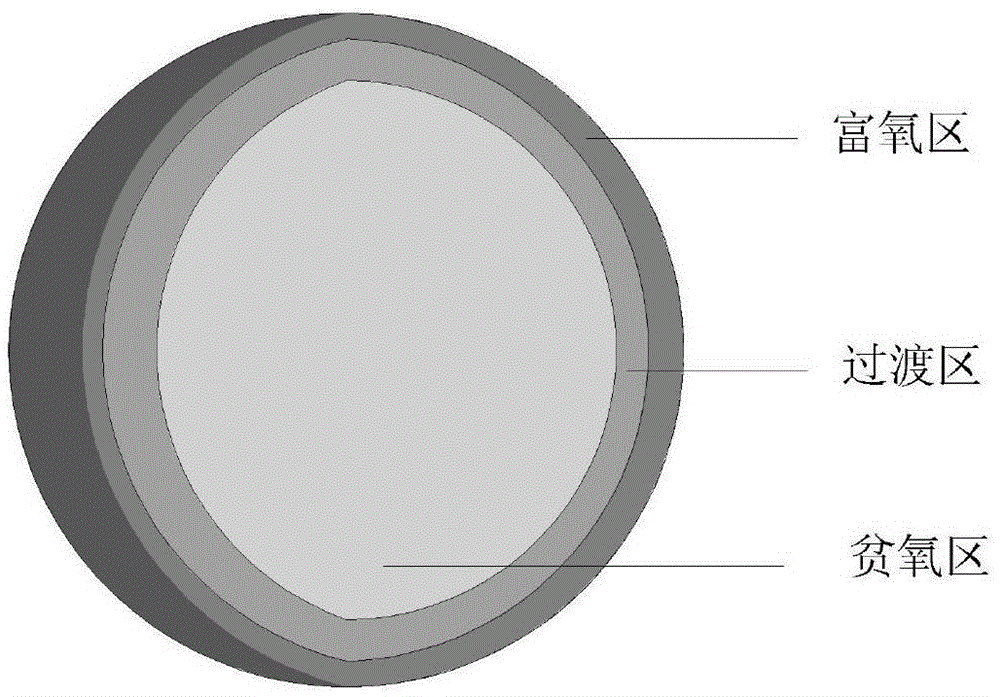

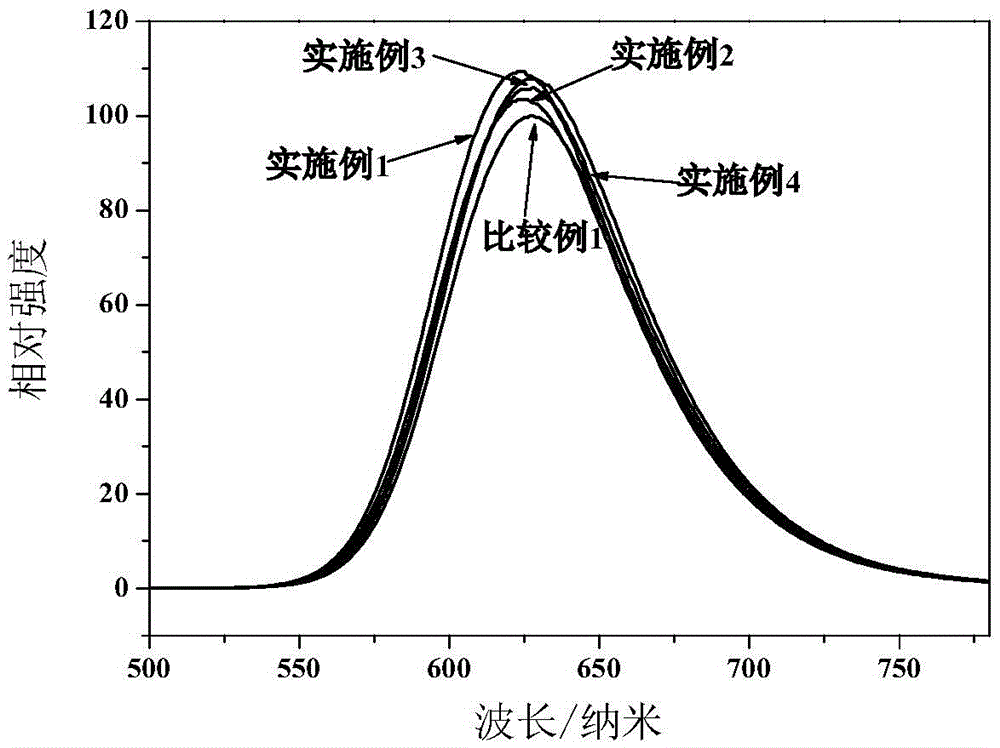

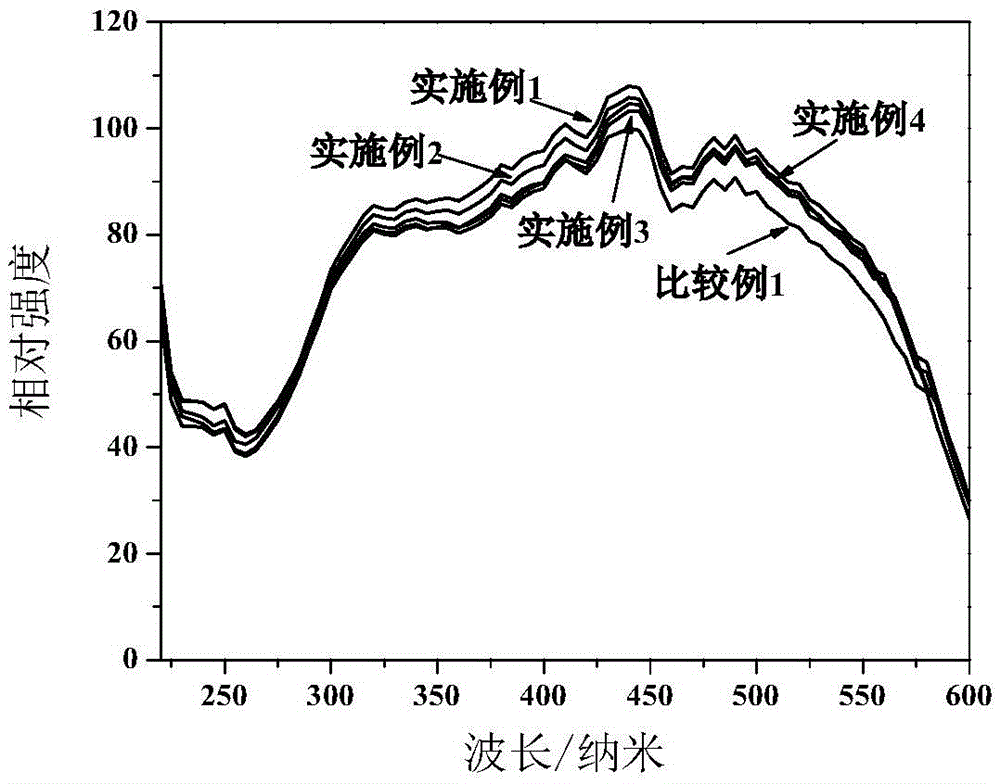

[0069] Weigh Ca 3 N 2 0.27g, Sr 3 N 2 9.954g, AlN4.477g, Si 3 N 4 5.107g, Eu 2 o 3 0.192g, the above raw materials were fully mixed in a nitrogen atmosphere for 3 hours, put into a molybdenum crucible, and then quickly moved into a tube furnace, and then gradually heated up to 1700°C under the protection of a nitrogen atmosphere, and kept for 12 hours; After the particles are crushed and sieved, put the sifted nitrogen-containing luminescent particles into deionized water and stir for 30 minutes, then filter with suction, and finally wash until the conductivity is 8.56μs / cm. After drying, heat up to 400°C, the calcination time is 5h, and the finished nitrogen-containing luminescent particles can be produced. For the emission spectrum see figure 2 , the excitation spectrum is shown in image 3 , X-ray diffraction pattern see Figure 4 . The chemical composition of the oxygen-poor region of nitrogen-containing luminescent particles is Ca 0.05 Sr 0.94 AlSiN 3 :0.01...

Embodiment 2

[0071] Weigh Ca 3 N 2 0.435g, Sr 3 N 2 9.712g, AlN4.512g, Si 3 N 4 5.147g, Eu 2 o 3 0.194g, the above raw materials were fully mixed in a nitrogen atmosphere for 3 hours, put into a molybdenum crucible, and then quickly moved into a tube furnace, and then gradually heated to 1700°C under the protection of a nitrogen atmosphere, and kept for 12 hours; After the particles are crushed and sieved, put the sifted nitrogen-containing luminescent particles into deionized water and stir for 30 minutes, then filter with suction, and finally wash until the conductivity is 4.42μs / cm. After drying, heat up to 400°C, the calcination time is 5h, and the finished nitrogen-containing luminescent particles can be produced. For the emission spectrum see figure 2 , the excitation spectrum is shown in image 3 , X-ray diffraction pattern see Figure 4 . The chemical composition of the oxygen-poor region of nitrogen-containing luminescent particles is Ca 0.08 Sr 0.91 AlSiN 3 :0.01Eu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com