Hot mold steel for long life cycle die casting having high thermal conductivity and method for preparing the same

A technology of hot die steel and manufacturing method, which is applied to the hot die steel for long-life die casting and its manufacturing field, can solve the problems of reduced die life, poor expansion rate, and high frequency of hot cracks, and achieves excellent high temperature durability and shortened cooling time. , excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 12 and comparative example 1 to 8

[0141] First, after preparing a steel ingot having the composition of the following Table 1 and Table 2, an electroslag remelting process was performed under an argon atmosphere, and a mold material was produced by forging at a temperature of 1180° C. at a forging ratio of 5.2S. The spheroidizing heat treatment was performed at a temperature of 800°C. After that, quenching, rapid cooling, and third tempering steps were performed under the conditions shown in Table 3 to manufacture hot die steel.

[0142] Table 1

[0143]

[0144] Table 2

[0145]

[0146]

[0147] table 3

[0148]

[0149]

experiment example 1

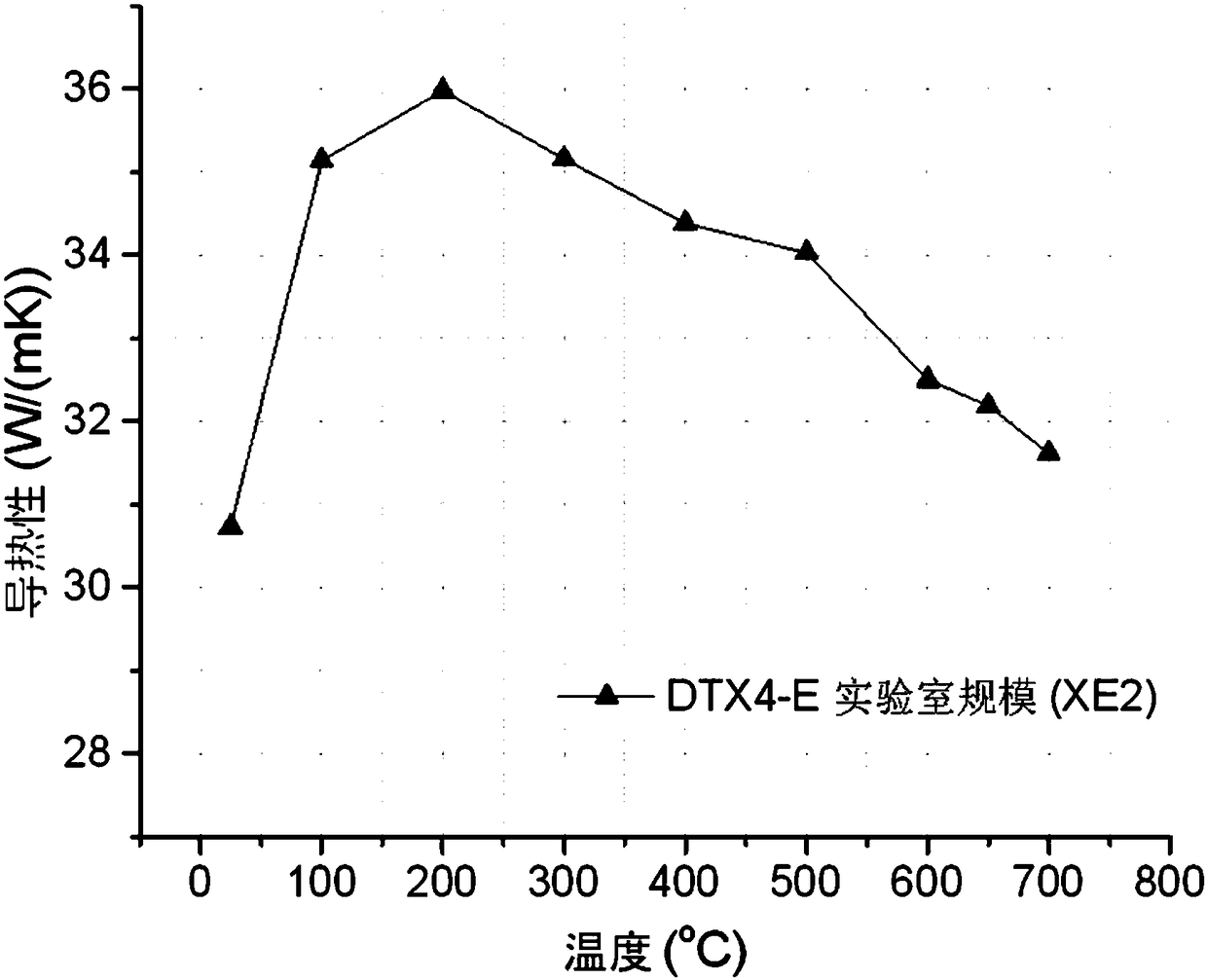

[0150] Experimental example 1. Thermal conductivity evaluation

[0151] The results of measuring the thermal conductivity at each temperature of the mold steel manufactured in Example 3 are shown in the following Table 4 and figure 1 shown

[0152] Table 4

[0153] temperature(℃)

Thermal conductivity (W / mK)

25

30.73

100

35.142

200

35.982

300

35.161

400

34.384

500

34.03

600

32.502

650

32.188

700

31.611

[0154] As stated in Table 4 and figure 1 As shown, the hot die steel produced according to the present invention has a thermal conductivity of 30 W / mK or more in an environment above normal temperature, and has a thermal conductivity of about 35 W / mK or above in a high temperature environment above 100 ° C, and has a thermal conductivity of 600 ~ 700 ° C It also has a thermal conductivity of more than 31W / mK in a very high temperature environment.

[0155] From this, it can be...

experiment example 2

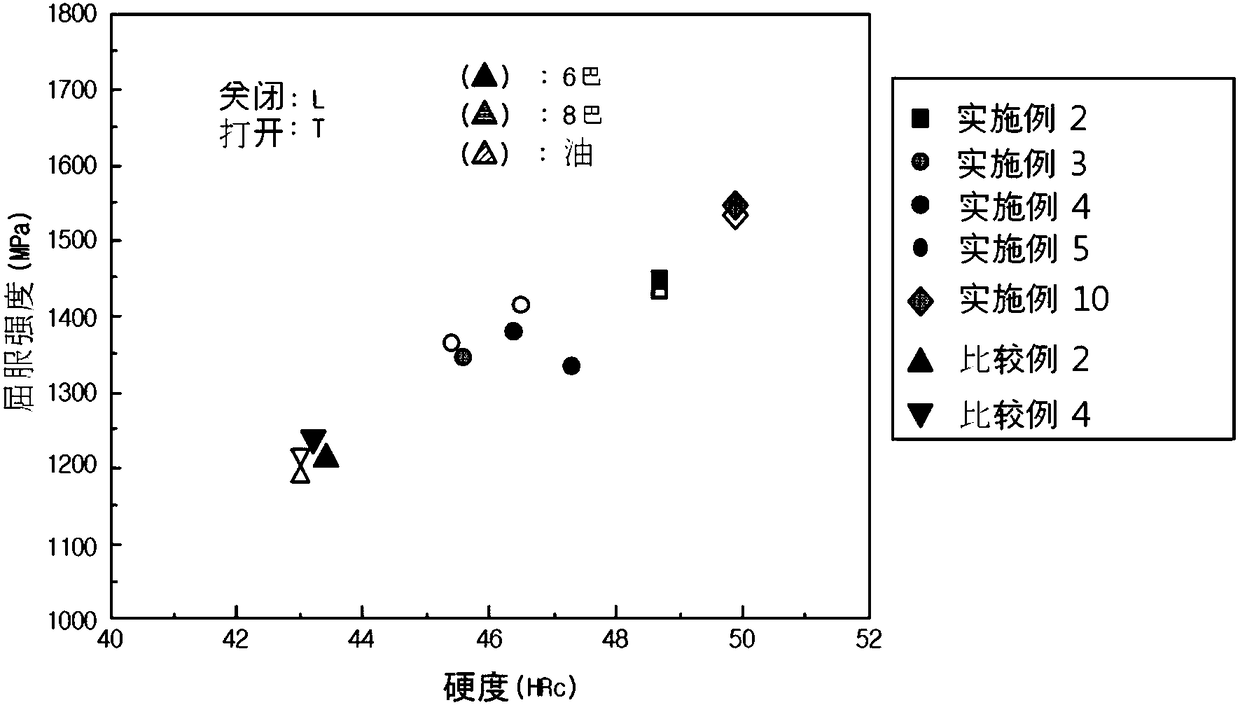

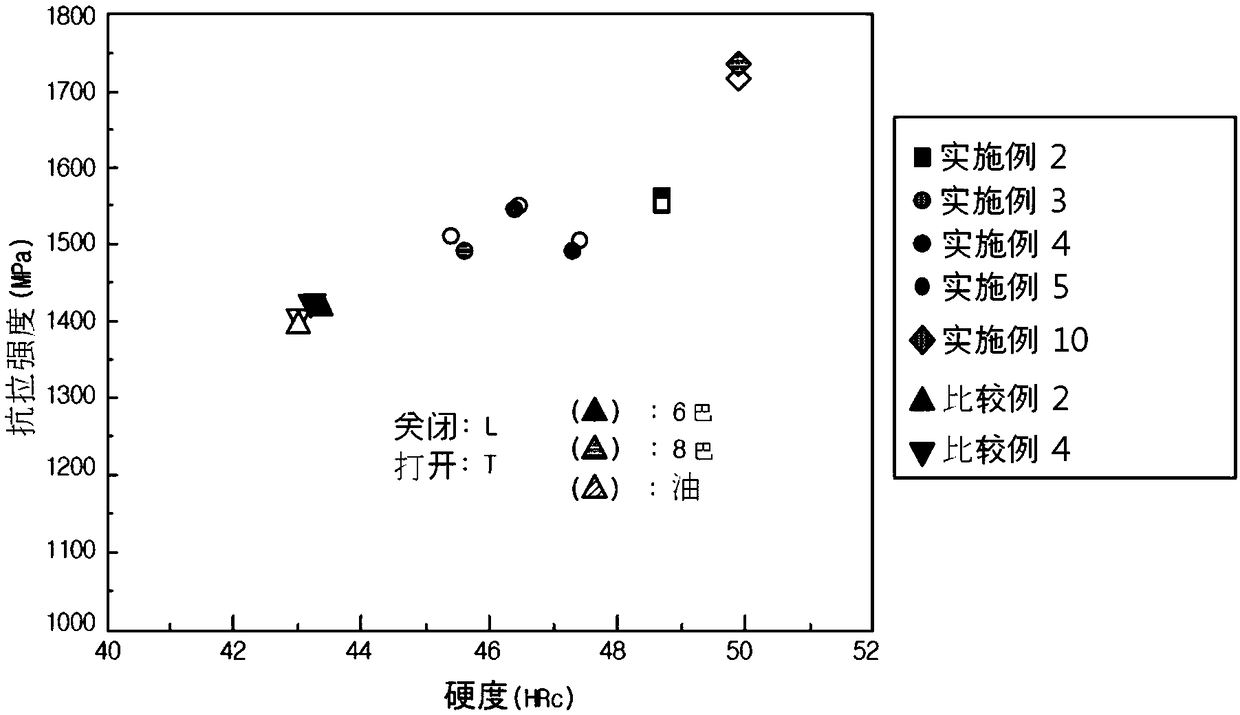

[0156] Experimental example 2. Physical property evaluation

[0157] In order to confirm the strength that changes with the content of chromium and titanium, figure 2 and 3 The graph of is showing the values of yield strength and tensile strength as a function of hardness of hot die steels manufactured in Examples 2, 3 to 5 and 10 and Comparative Examples 2 and 4, Figure 4 The graph shows the value of impact energy as a function of hardness

[0158] Such as figure 2 and 3 As shown, in the case of Examples 2, 3 to 5 and 10 where the chromium content is within the scope of the present invention, the results show that the hardness, yield strength (Yield Strength) and tensile strength (Tensile Strength) are very high, but , in the case of Comparative Examples 2 and 4 in which the chromium content deviates from the range of the present invention, it can be seen that the hardness and yield strength have remarkably low values. In addition, in the case of Example 10, compare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com