Grease composition and grease-sealed bearing

A lubricating grease composition and technology of lubricating grease, applied in lubricating compositions, ball bearings, bearing components, etc., can solve the problems of low viscosity lubricant effect and unclear improvement effect of high temperature durability, and achieve thickening Excellent, high temperature durability improvement, low viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 3

[0052] Using the compounding ratio shown in Table 1, a grease composition was prepared using a base oil, a thickener, and a corrosion inhibitor. The ionic liquid as the base oil has a cationic component of 1-octyl-3-methylimidazole 1-octyl-3-methylimidazole manufactured by Merck whose cation and anion components are bis-trifluoromethylsulfonyl-imide anion - Bis-trifluoromethylsulfonyl-imide (shown in Formula 5 below, represented by OMI-TFSI in Table 1). The grease composition obtained was used as the grease composition for testing, and the following high-temperature, high-speed grease life test was carried out to measure the high-temperature, high-speed grease life time. The results are recorded in Table 1 together.

[0053] [chemical 5]

[0054]

[0055]

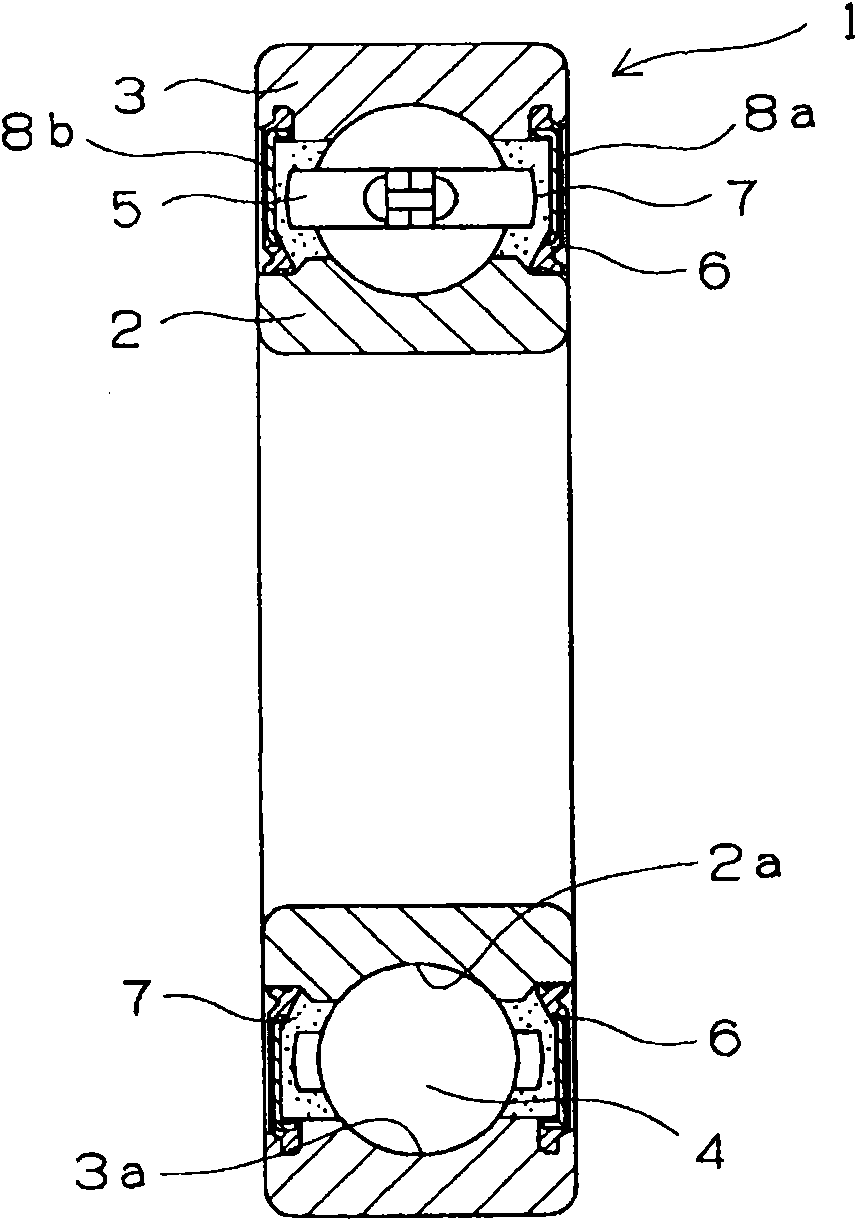

[0056] Enclose 38% of the total space volume of the obtained test grease in the rolling bearing 6204 (inner diameter 20mm×outer diameter 47mm×thickness 14mm). °C, rotated at a rotation speed of 10000rpm, and the ...

Embodiment 4、 Embodiment 6~ Embodiment 10 and comparative example 7

[0058] Using the compounding ratio shown in Table 1, a grease composition was prepared using a base oil, a thickener, and a corrosion inhibitor. The ionic liquid as the base oil has a cationic component of 1-hexyl-3-methylimidazole 1-hexyl-3-methylimidazole manufactured by Merck whose cation and anion components are bis-trifluoromethylsulfonyl-imide anion - Bis-trifluoromethylsulfonyl-imide (shown in Formula 6 below, represented by HMI-TFSI in Table 1). The obtained grease composition was used as the test grease, and the above-mentioned high-temperature, high-speed grease life test was carried out to measure the high-temperature, high-speed grease life time. The results are recorded in Table 1 together.

[0059] [chemical 6]

[0060]

Embodiment 5

[0062] Using the compounding ratio shown in Table 1, a grease composition was prepared using a base oil, a thickener, and a corrosion inhibitor. The ionic liquid as the base oil has a cationic component of 1-hexyl-3-methylimidazole 1-hexyl-3-methylimidazole manufactured by Merck whose cation and anion components are trifluoro-tris(pentafluoroethyl)phosphide anion -Three(pentafluoroethyl)-trifluorophosphides (as shown in the following compound 7, HMI-(C 2 f 5 ) 3 PF 3 - express). The obtained grease composition was used as the test grease, and the above-mentioned high-temperature, high-speed grease life test was carried out to measure the high-temperature, high-speed grease life time. The results are recorded in Table 1 together.

[0063] [chemical 7]

[0064]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com