High-fire resistance A1-Cu-Mg-Ag alloy

A high heat-resistant, al-cu-mg-ag technology, applied in the field of Al-Cu-Mg-Ag alloys, can solve the problem of decreased thermal stability of alloys, decreased nucleation sites of Ω phases, decreased overall quantity and density of Ω phases, etc. problems, to achieve the effect of good high-temperature durable performance and excellent high-temperature short-term tensile performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

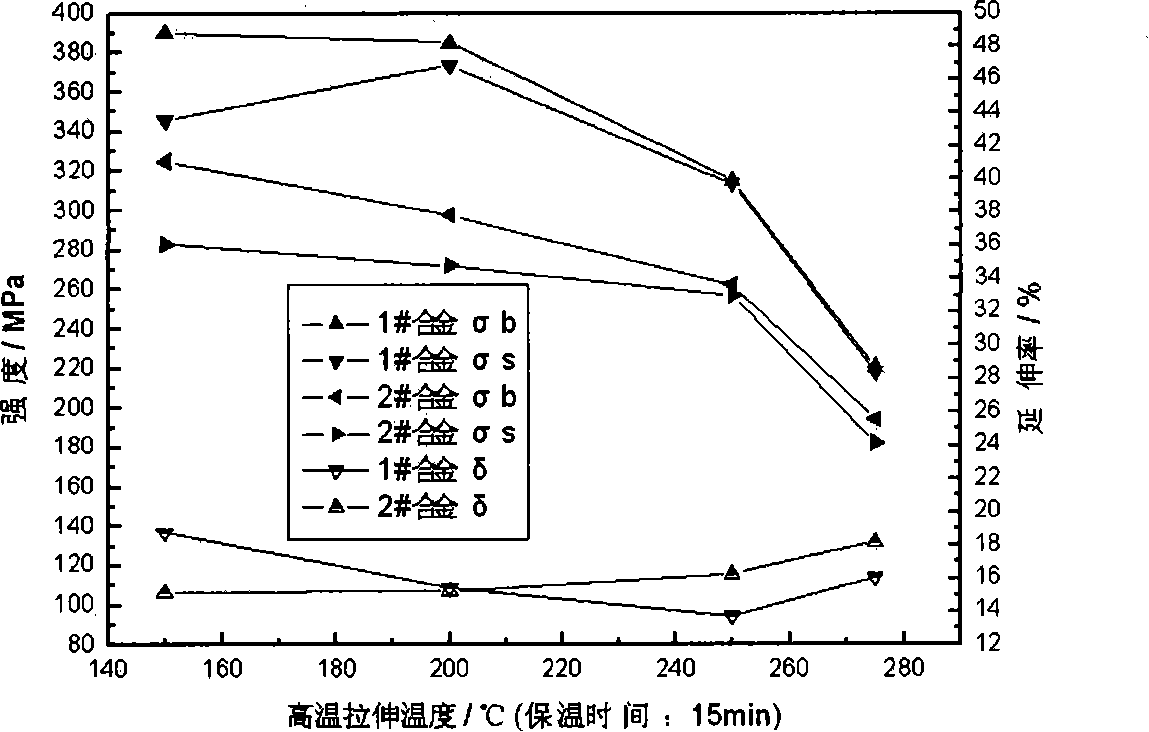

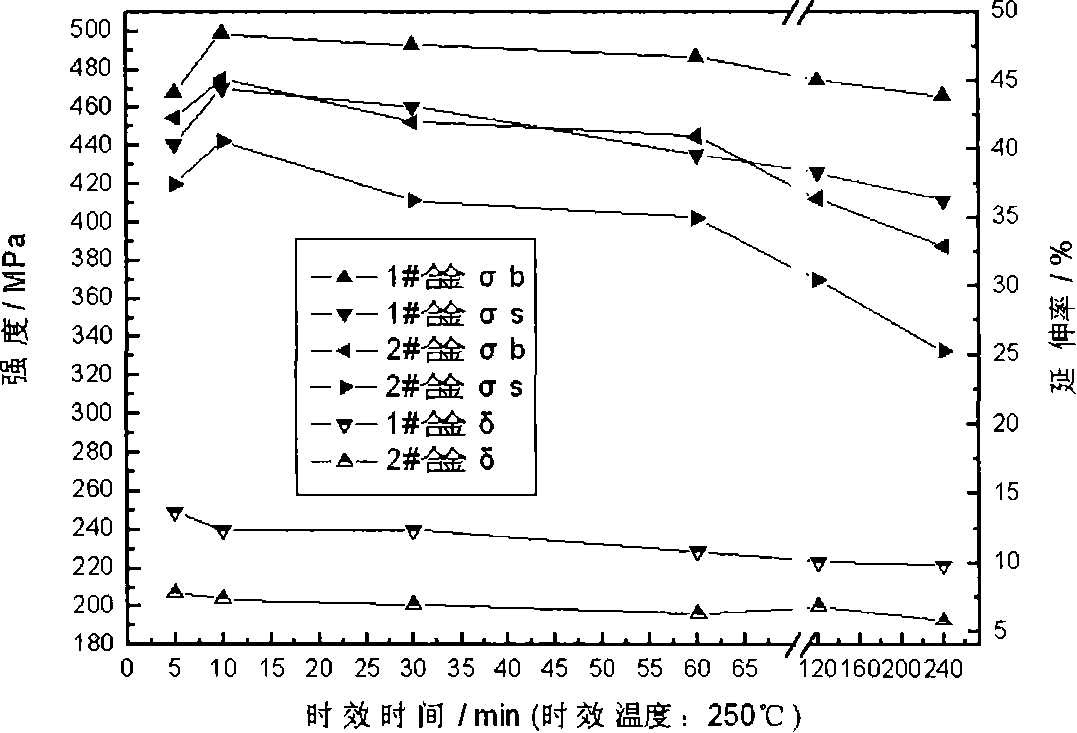

[0016] Proportion each alloy element according to Table 1, prepare 1# and 2# alloy ingots by smelting and casting, hot-roll into thin plates, solid solution at 515°C for 6 hours and water quenching, then aging at 165°C for 2 hours, oil bath slow cooling. The two alloys were held at 150°C, 200°C, 250°C and 275°C for 15 minutes, respectively, and then stretched at high temperature for a short time. After stretching at 150°C, the tensile strength of 1# alloy is 390MPa, and the tensile strength of 2# alloy is 325MPa. The tensile strength, yield strength and elongation of the two alloys after being stretched at 200°C, 200°C, 250°C and 275°C are as attached figure 1 shown. The data show that under the same heat treatment conditions, the short-term tensile properties of high-Ag alloys are better than those of low-Ag alloys. During the stretching process, the degree of aggregation and coarsening of the Ω-reinforced phase is not obvious, so it still has high tensile strength and yie...

Embodiment 2

[0018] Proportion the alloy elements according to Table 1, prepare 1# and 2# alloy ingots by smelting and casting method, hot-roll into thin plates, solid solution at 515°C for 6 hours and water quenching, and then aging at 165°C for 2 hours. After the treatment, the two alloys were subjected to high-temperature endurance tests at 200° C. respectively. The experimental results are: 1# alloy at 200°C, the endurance strength limit of 100 hours is 240Mpa, that is σ 100 200 = 240 Mpa ; 2# alloy is at 200℃, and the endurance strength limit of 100 hours is 220Mpa, that is σ 100 200 = 220 Mpa . The data show that: under the same heat treatment conditions, the high-temperature durability of high-Ag alloys is better than that of low-Ag alloys.

Embodiment 3

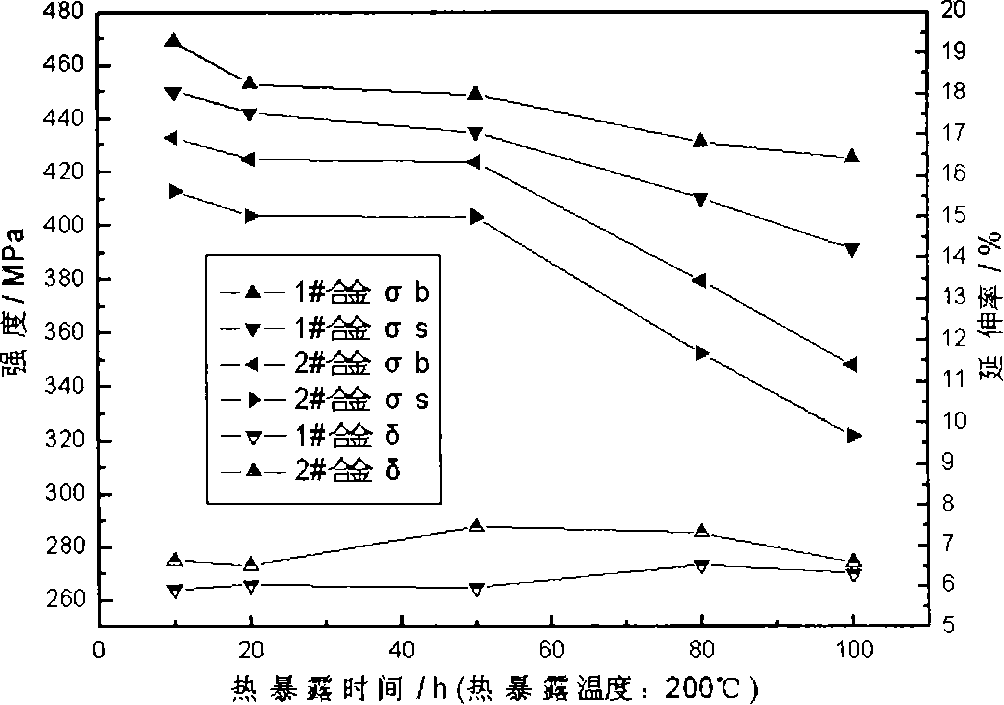

[0020] Proportion the alloy elements according to Table 1, prepare 1# and 2# alloy ingots by smelting and casting method, hot-roll into thin plates, solid solution at 515°C for 6 hours and water quenching, and then aging at 165°C for 2 hours. The two alloys after this treatment were subjected to heat exposure experiments at 200° C., and the heat exposure time was 10 hours, 20 hours, 50 hours, 80 hours and 100 hours. After the thermal exposure, the samples were mechanically stretched at room temperature. The experimental results are: the tensile strength of 1# alloy after 10 hours, 20 hours, 50 hours, 80 hours and 100 hours of heat exposure is 469.16MPa, 453.16MPa, 449.08MPa, 431.22MPa and 425.24MPa, and the yield strength is sequentially 450.37MPa, 442.44MPa, 435.06MPa, 410.55MPa and 391.25MPa, the elongation is 5.92%, 6.04%, 5.96%, 6.54% and 6.32%; 2# alloy after 10 hours, 20 hours, 50 hours, 80 hours and After 100 hours of heat exposure, the tensile strength is 432.89MPa, 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com