Al-Cu-Mg-Ag alloy and preparation method and application thereof

An al-cu-mg-ag, alloy technology, which is applied in the field of non-ferrous metal material alloying and its preparation, can solve the problem of high production cost, achieve low requirements for production equipment, excellent strength performance, and simple and easy-to-operate production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

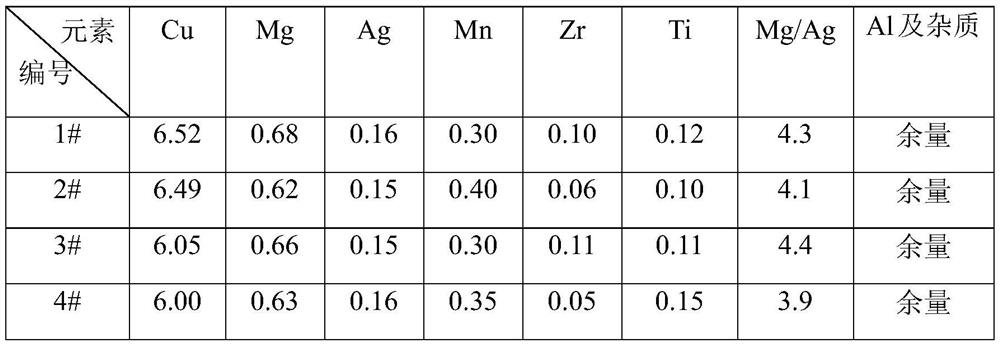

[0041] The alloy composition was prepared according to the 1# sample shown in the alloy composition table of the following Table 1, smelted at 750° C., and subjected to on-line degassing and slag removal and semi-continuous casting treatment to obtain an ingot. The ingot is subjected to two-stage homogenization heat treatment, and the specific process is as follows: firstly, the ingot is kept at 410°C for 18h, and then at 485°C for 48h. The homogenized heat-treated material is extruded into rod-shaped profiles at 400°C, and then subjected to solution aging treatment. The specific process is as follows: the solution system is kept at 520°C for 2 hours, and the aging system is kept at 165°C for 32 hours.

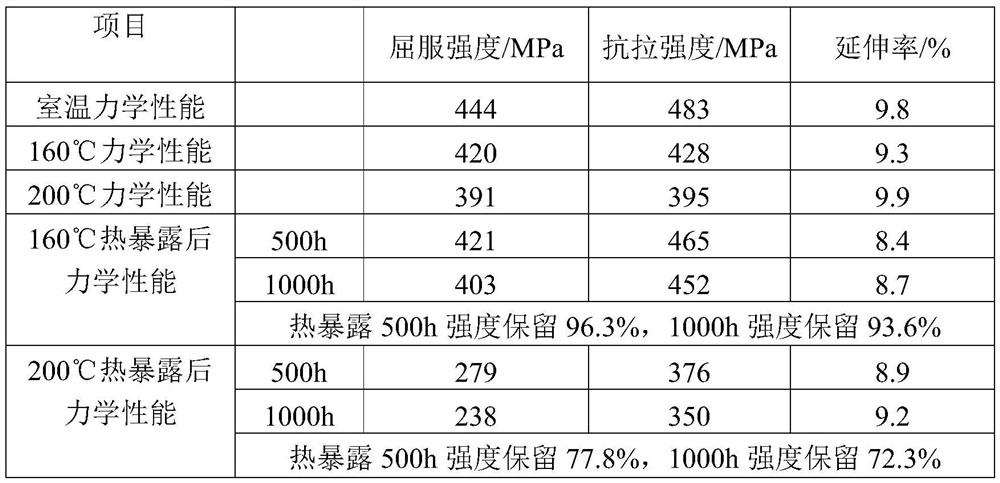

[0042] The obtained 1# alloy was tested for strength, including room temperature mechanical property test, mechanical property test under high temperature conditions of 160°C and 200°C, and mechanical property test after thermal exposure under high temperature conditions of 160...

Embodiment 2

[0044] The alloy composition was prepared according to the 2# sample shown in the alloy composition table of the following Table 1, smelted at 750° C., and subjected to in-line degassing and slag removal and semi-continuous casting treatment to obtain an ingot. The ingot is subjected to two-stage homogenization heat treatment, and the specific process is as follows: firstly, the ingot is kept at 410°C for 18h, and then at 485°C for 48h. The homogenized heat-treated material was hot-extruded into a rod-shaped profile at 400 °C, and then subjected to solution aging treatment. The specific process was: the solution system was kept at 520 °C for 2 hours, and the aging system was maintained at 165 °C for 32 hours.

[0045] The obtained 2# alloy was tested for strength, including room temperature mechanical property test, mechanical property test under high temperature conditions of 160°C and 200°C, and mechanical property test after thermal exposure under high temperature conditions...

Embodiment 3

[0047] The alloy composition was prepared according to the 3# sample shown in the alloy composition table of the following Table 1, smelted at 750° C., and subjected to in-line degassing and slag removal and semi-continuous casting treatment to obtain an ingot. The ingot is subjected to two-stage homogenization heat treatment, and the specific process is as follows: firstly, the ingot is kept at 410°C for 18h, and then at 485°C for 48h. The homogenized heat-treated material is extruded into rod-shaped profiles at 400 °C, and then subjected to solution aging treatment. The specific process is as follows: the solution system is kept at 520 °C for 2 hours, and the aging system is maintained at 165 °C for 12 hours.

[0048] The obtained 3# alloy was subjected to strength tests, including room temperature mechanical property test, mechanical property test under high temperature conditions of 160°C and 200°C, and mechanical property test after thermal exposure under high temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com